Guangdong Yonglong Aluminum Co., Ltd. |

|

Broken bridge aluminum doors and windows are mainly made of

heat-insulating broken bridge aluminum profiles and insulating

glass, which have the functions of energy saving, sound insulation,

noise prevention, dust prevention, waterproof and so on.

advantage:

1. Good thermal insulation;

2. There is a drainage outlet designed to ensure smooth drainage

and good water tightness;

3. The three-way sealing structure separates the water vapor

chamber, realizes the balance of water pressure and air pressure,

and prevents condensation and frost;

4. Metal material, heat insulation strip, high temperature

resistance, non combustion, fire prevention function;

5. Broken bridge aluminum doors and windows do not produce harmful

materials in the production process, and the materials can be

recycled, which belongs to green building materials;

6. High strength, not easy to deformation and corrosion, almost no

maintenance.

Disadvantages:

1. To achieve the thermal insulation performance of broken bridge

aluminum doors and windows, PA66 thermal insulation strip is

required, but its price is high, so the price of broken bridge

aluminum doors and windows is also high.

2. In addition, because PVC spacer is cheaper, some illegal

businesses may cut corners, so they need to pay more attention when

purchasing.

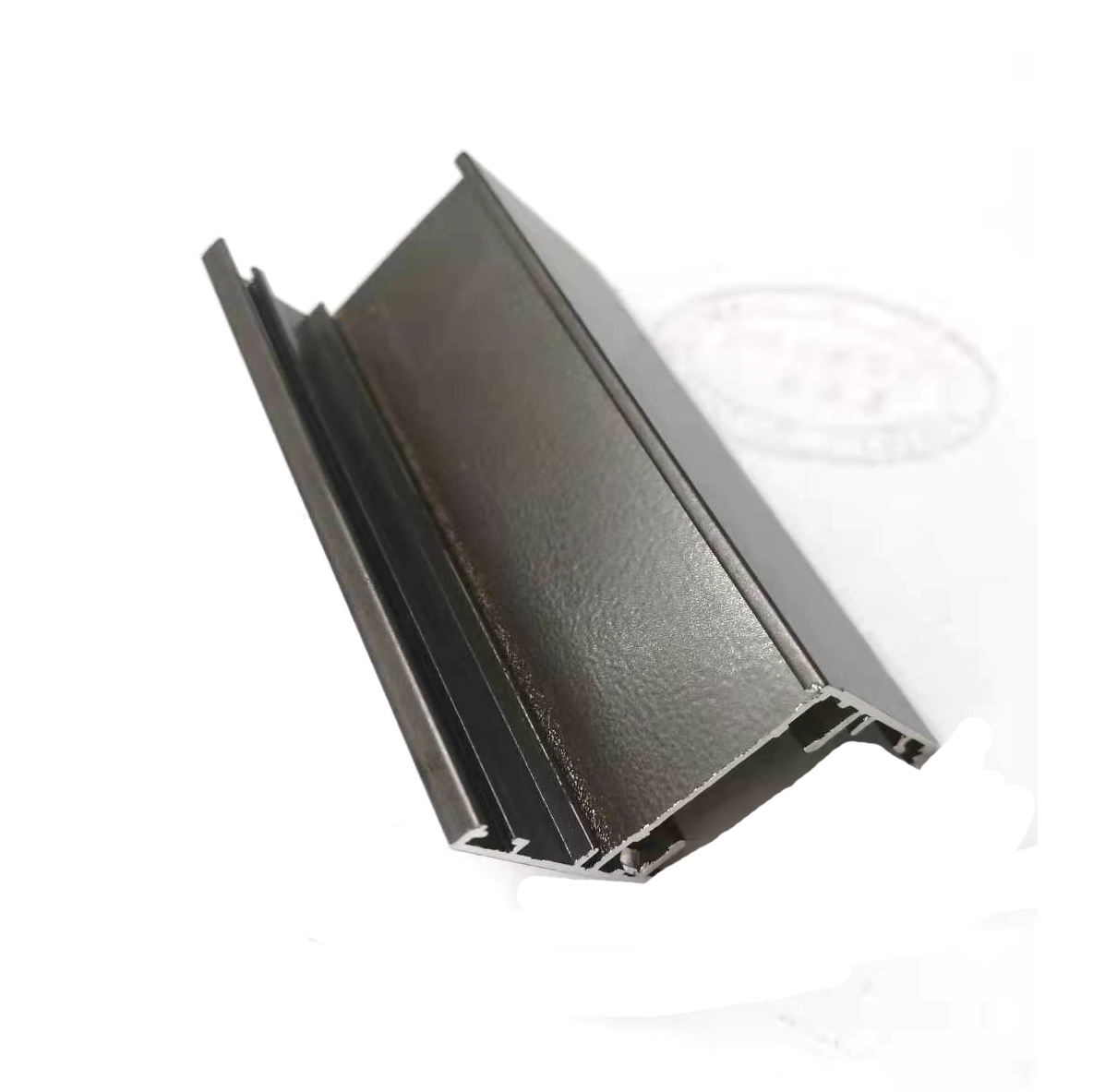

| Description | Construction Aluminum Window Profiles Casement Window Frame Set Building Materials |

| Material Thickness(t) | 0.8-2.0 mm |

| Materiral | aluminum alloy 6063 |

| Annealing Treatment | T3-T8 |

| Color | Wood, Silver White ,Bronze , Champagne, Black, (RAL series)etc. |

| Surface Treatment | anodized, powder coated, electrophoresis, wood grain, polished and etc |

| Shape | Square, Round, Flat, Oval, and according to customer's drawing. |

| Length | Normal length=6m or in customer's order |

| Usage | Building, Production Line, Decoration, Industrial, Transportation, Door and window, etc. |

| Package | 1. Pearl cotton foam for each profile; 2. Wrap with shrink film exterior; 3. Packed according to customer request. |

| Advantages/Features | Providing colorful products with various mechanical performances to adapt all kinds of architectural styles |

Anode effect is a special phenomenon in molten salt electrolysis, especially in electrolytic aluminum production. In production, when the anode effect occurs, the voltage of the electrolytic cell rises sharply, reaching 20 ~ 50V, sometimes even higher. Its occurrence has a great impact on the whole electrolysis series, reduces the current efficiency, affects various technical indexes of electrolysis, reduces the output and quality of aluminum, and destroys the stable power supply of the whole electrolysis series. In terms of treatment methods, there are no more than two kinds: extinguish with effect rod (wood rod), or reduce the anode and increase the blanking amount of alumina, so as to extinguish the anode effect. No better treatment has been found.

The anode effect occurs because the oxygen-containing ions in the

electrolyte gradually decrease with the progress of the

electrolysis process. When it reaches a certain degree, fluorine

precipitates and reacts with the anode carbon to form carbon

fluoride. When the carbon fluoride decomposes, fine carbon

particles are precipitated. These carbon particles are attached to

the anode surface to prevent the contact between the electrolyte

and the anode, The electrolyte can't wet the anode well, just as

water can't wet the oiled surface, so a layer of gas film with poor

conductivity is formed between the electrolyte and anode, and the

anode overvoltage increases, causing the anode effect. When new

alumina is added, oxygen is precipitated on the anode, which reacts

with carbon powder to gradually calm the anode surface, reduce the

resistance, and the electrolysis process tends to be normal.

Q – What is the average lead time for pre production samples?

A – Our average lead time is normally 7 days for making new samples and 7 days for testing , totally need about 14days.

Q – What is the average lead time for mass production?

A – Our average lead time is delivery within 20-30 days after receive deposit and and moulds/samples are passed.

Q – What is CAD?

A – CAD stands for “computer assisted design” and it is a 3-D program that is used by our clients to provide our technicians with a three-dimensional example of the custom shape that they want made at GUANGDONG YONGLONG ALUMINUM.Aluminium Window Profiles