ruian chuangbo machine co.,ltd |

|

Type 90 Foot Mount Steel Safety Chucks STO STW 90 Safe Chuck Torque

1000kgfm

Introduction

Safety Chuck is for continuous action of the shaft (air shaft) to provide fast, accurate, simple, safe and effective connection device.

They provide economic and easy to install, the design, and for the transmission links. Safety chuck allow to load or unload rolls more easily without moving the airshaft directly. Any model can be both foot-mounted and flange-mounted. Biggest mode is type 230.

| Size | Maximum load | Maximum torque | Standard square bar size | Unit Weight |

| FLO/FLW STW/STO 28 | 800 kg | 18 KGFM | 25/30 mm(22~30 mm avaiable) | 18 KG |

| FLO/FLW STW/STO 35 | 1600 kg | 35 KGFM | 32/38 mm (30~4O mm avaiable) | 27 KG |

| FLO/FLW STW/STO 50 | 2800 kg | 110 KGFM | 40/45/50 mm (40~50 mm avaiable) | 53 KG |

| FLO/FLW STW/STO 75 | 7000 kg | 235 KGFM | 55/65/75 mm (50~80 mm avaiable) | 120 KG |

| FLO/FLW STW/STO 90 | 12000 kg | 1000 KGFM | 80~120 mm | 300 KG |

| FLO/FLW STW/STO 120 | 22000 kg | 2000 KGFM | 120~180 mm | 600 KG |

| FLO/FLW STW/STO 180 | 32000 kg | 2500 KGFM | 170~200 mm | 1000 KG |

| FLO/FLW STW/STO 230 | 64000 kg | 4100 KGFM | 170~230 mm | 1200 KG |

Application

Printing machinery

Bag making machinery

Paper machinery

Roll of wire machinery

Bundle bag machinery

Textile machinery

Other machinery

Features

Advantage

How do you operate a Safety Chuck?

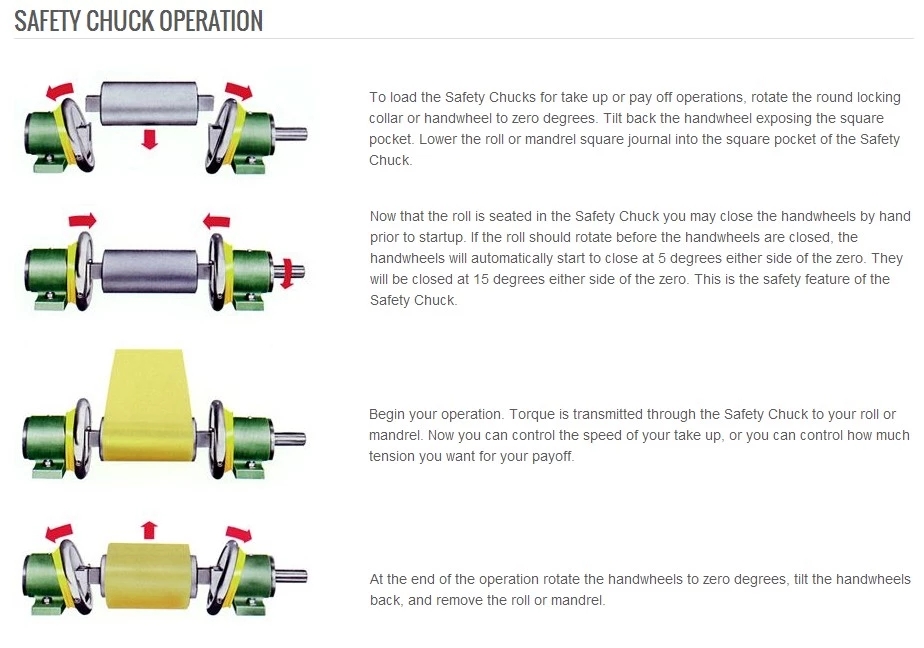

1. To load the Safety Chucks for take up or pay off operations, rotate the round locking collar or handwheel to zero degrees. Tilt back the handwheel exposing the square pocket. Lower the shaft square journal into the square pocket of the Safety Chuck.

2. When the shaft is seated in the Safety Chuck the handwheels are closed by hand prior to start up. If the roll should rotate before the handwheels are closed, the handwheels will automatically start to close at 5 degrees either side of the zero. They will be closed at 15 degrees either side of the zero. This is the safety feature of the Safety Chuck.

3. Start the operation. Torque is transmitted through the Safety Chuck to the shaft. The speed of the take up and, the amount of tension required can be controlled with the inclusion of a compatible Boschert Brake.

4. At the end of the operation rotate the handwheels to zero degrees, tilt the handwheels back and remove the Air Shaft

Why choose CBB Chuangbo

A. Reliable supplier in China

Established in 1995, CBB Chuangbo has been in machinery parts for 25 years, now we are biggest manufacturer of machinery parts in East China.

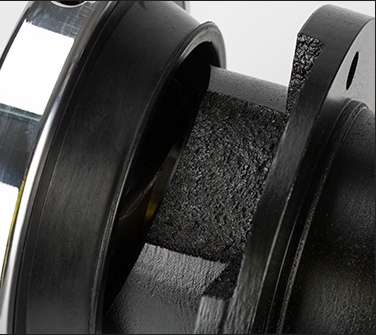

B. Hight quality material

High quality of steel shell for the brake and imported powder for longer life of the brake.

C. Cooling treatment

Insider there is a small cooling fan inside the brake, cooling the tempreture and make the brake stable.

D. Quality control

We have the quality control system during the whole production fromthe very beginning to the end and our principle is to make sure each shaft is qualified.