ruian chuangbo machine co.,ltd |

|

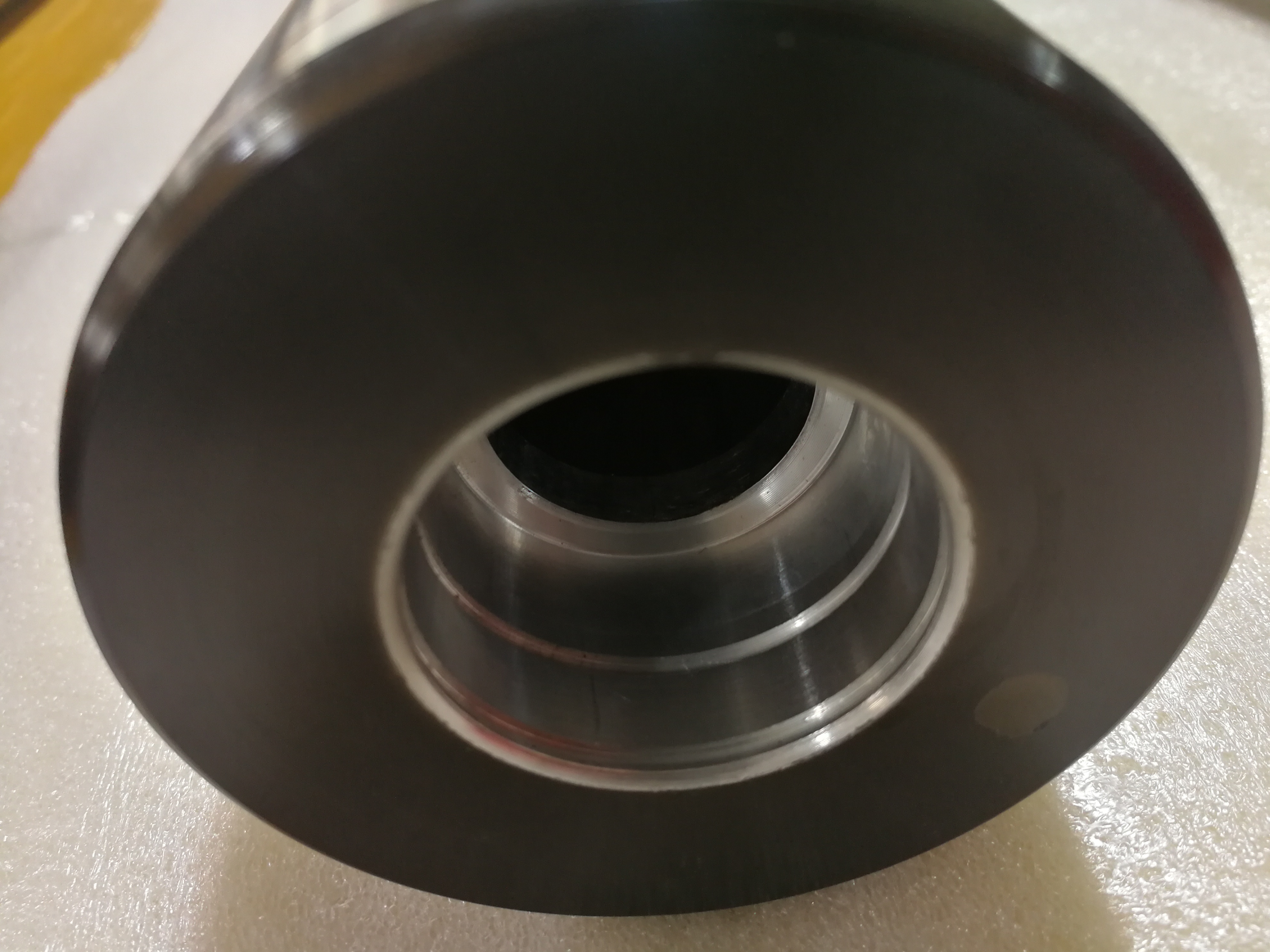

Hard Oxidation Aluminum Idler Roller HV700 Center Groove Light Weight

Briefly

Aluminum idler roller is made of high quality aluminum alloy material 6061/6063 T6, which is high plasticity and strong structure. It has all kinds of modules and sizes with ribs structure and the outside diameter is from 25mm to 320mm. Under the cheat by computer balancing correction process, the dynamic balance of the aluminum roller will be small than 2g. With using of sophisticated equipment and special tools, the roll surface gloss can be 0.8, concentricity can reach to 0.02mm.

Aluminum idler roller is much lighter than steel roller, journal configuration, roll diameter and face length is customized to meet your application.

Specification

| Production | Aluminum Idler Roller |

| Length | Max.6,000mm |

| Diameter | Max.320mm |

| Material | Aluminum 6063 T6, aluminum 6061 T6, etc. |

| Surface Treatment | Hard anodized, anodized |

| Runout | ≥0.01mm |

| Dynamic Balance | G2.5 |

| Surface Roughness | Grinding: ≤Ra0.8um; Mirror-like: ≤Ra0.4um |

| Surface Hardness | Could be ≥700HV |

| Application Fields | Printing, converting, plastic film, textile machinery, etc. |

| Package | Wooden case |

| Type of roller | Hollow type |

| Dead shaft type | |

| Live shaft type | |

| Surface treatment | HV300 soft anodize |

| HV700 hard anodize | |

| HV700 hard anodize with mirror surface | |

| Teflon | |

| Surface groove | Plain |

| Cross line | |

| Center line | |

| Grooved line | |

| Anilox line | |

| Rolla line |

Features

Proper smoothness of the surface and groove on the surface will reduce web slippage and get better tension control. Reduce bearing side-thrust, longer the life of the bearings.

In the printing machines, there are a lot of chemicals and dust, proper quantity of aluminum guide rollers are with live shaft and with dead shaft can make the life of the bearings for the machines much longer

Advantages

a.There is a rib structure in the aluminum guide roller, which makes it very strong.

b.We use precision equipment and special tools to finish the surface to make the surface smooth and the concentricity reaches 0.02mm.

c.Dynamic balance accuracy within 2g

In the production process, through the hot set matching process and the appearance of the CNC lathe, the aluminum guide roller can obtain high bonding strength and precision, good linearity and concentricity, and a high-speed dynamic balancing system can ensure static balance With high-speed dynamic balancing performance, it can ensure that aluminum guide rollers run on the machine at high speed without vibration.

d.Low resistance, light weight, flexible rotation, no rust, wear resistance and corrosion resistance

Application

Aluminum idler rollers are widely used in printing, packaging plastics, paper, glass, pharmaceutical, electronics batteries, textile machinery and industries.

Sizes

| Finished Diameter/mm | Material Diameter/mm | Inner Diameter/mm | Thickness |

| φ22 | φ22.7 | φ15 | 3.85 |

| φ25 | φ25 | φ18 | 3.5 |

| φ28 | φ28 | Φ22 | 3 |

| φ30 | φ30.1 | φ20.1 | 5 |

| φ34 | φ33.8 | φ25.4 | 4.2 |

| φ35 | φ35 | φ26 | 4.5 |

| φ38 | φ38.2 | φ30.2 | 4 |

| φ40 | φ40.1 | φ30.1 | 5 |

| φ42 | φ42 | Φ33 | 4.5 |

| φ45 | Φ45 | Φ35 | 5 |

| φ50 | φ50.2 | φ40.2 | 5 |

| φ51 | φ51 | Φ38.6 | 6.2 |

| φ52 | φ52.3 | φ45.3 | 3.5 |

| φ55 | φ55 | φ45 | 5 |

| φ57 | φ57.2 | φ50.2 | 3.5 |

| φ60 | φ60 | φ50 | 5 |

| φ61 | Φ60.6 | Φ50.6 | 5 |

| φ70 | φ70 | φ61.0 | 4.5 |

| φ72 | φ72.4 | φ64.4 | 4 |

| φ75 | φ75 | φ66 | 4.5 |

| φ75 | φ75 | φ60 | 7.5 |

| φ77 | φ77.4 | φ70 | 3.7 |

| φ80 | φ81.3 | φ73.7 | 3.8 |

| φ80 | φ80.2 | φ70 | 5.1 |

| φ80 | φ80 | φ64 | 8 |

| φ90 | φ90.5 | φ82.9 | 3.8 |

| φ90 | φ90.6 | φ75.6 | 7.5 |

| φ100 | φ100.5 | φ92.5 | 4 |

| φ100 | φ100.8 | φ89.80 | 5.5 |

| φ110 | φ111 | φ101.8 | 4.6 |

| φ120 | φ121.8 | φ111.8 | 5 |

| φ120 | φ120.4 | φ108.4 | 6 |

| φ130 | φ131 | φ120 | 5.5 |

| φ150 | φ151.5 | φ139.5 | 6 |

| φ150 | φ151.5 | φ135.5 | 8 |

| Φ162 | Φ162.5 | Φ146.5 | 8 |

| Φ172 | Φ172.2 | Φ156.2 | 8 |

| φ180 | φ180 | φ160 | 10 |

| φ200 | φ202 | φ186 | 8 |

| φ240 | φ240 | φ208 | 16 |

| Φ320 | Φ320 | Φ296 | 12 |

About CBB Chuangbo:

Ruian Chuangbo Machinery Co., Ltd. formerly named Ruian Feiya Electromechanical Equipment Co., Ltd. established in 1995, is located in Nanbin Street Industrial Zone, Ruian City, Zhejiang Province, PRC.

The company is specialized in manufacturing of machinery parts, and has been granted with independent import and export rights. Our products widely used in printing, packaging, plastics, pharmaceuticals, textiles machinery and industries.

The company implements ISO9001 standards and striving for excellence to ensure the product as leading ranks for domestic and international markets. The products sold to allover the country and export to more than thirty countries and regions, such as: Germany, the United States, Israel, Russia, Spain, Portugal, Canada, India, the United Arab Emirates, Pakistan and so on.