Dongguan Xinlong Non Woven Machinery Equipment Co., Ltd. |

|

Verified Suppliers

|

|

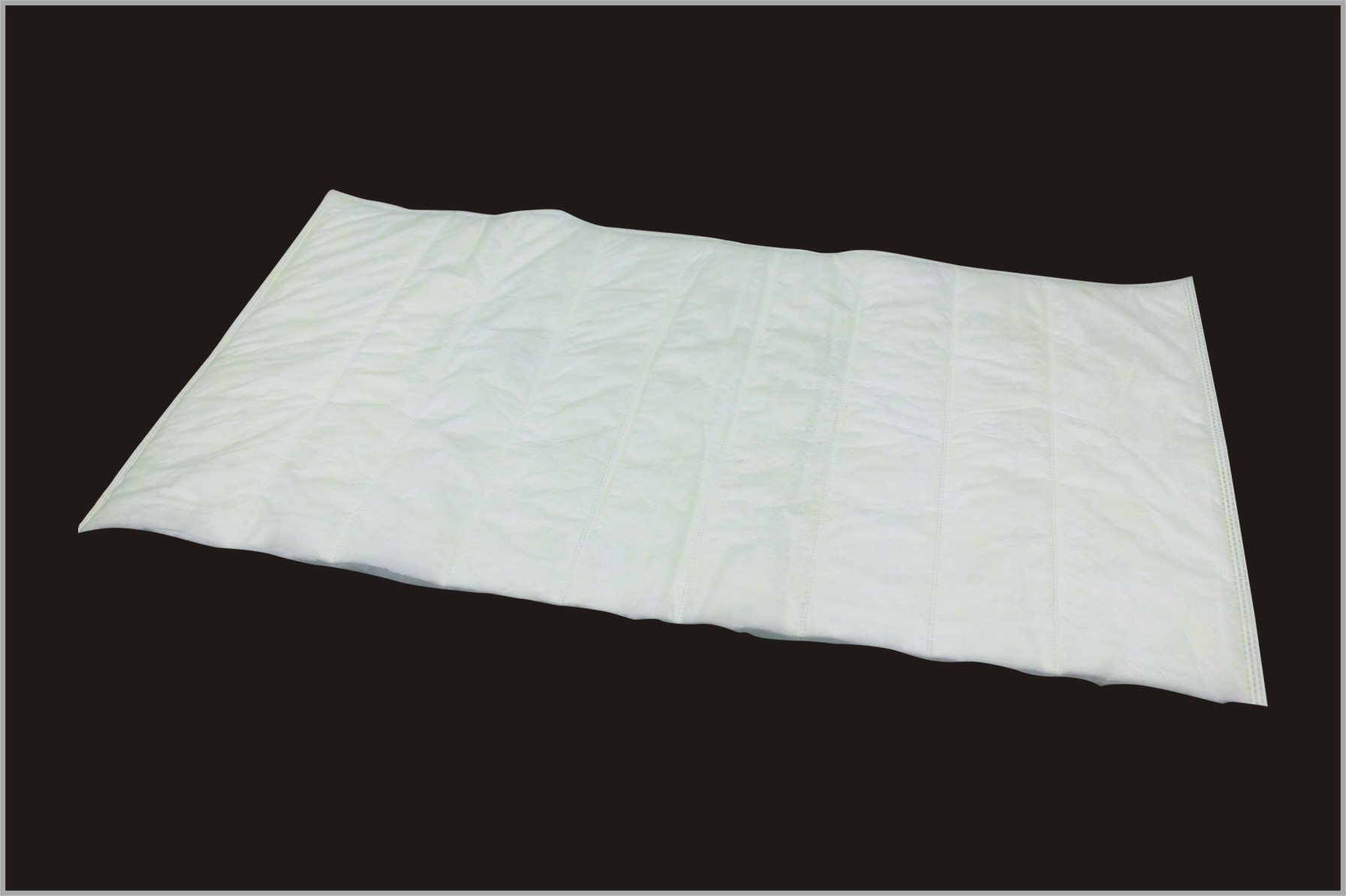

7.5KW A Special Machine For Cutting Non-Woven Primary And Secondary Filter Bags

XL-60 Ultrasonic Nonwoven Filter Bag Dust Bag Slicing Machine

XL-60 is a special machine for cutting non-woven primary and secondary filter bags, from raw material to finished product is an automatic operation. It is neat, time-saving, and the cutting length can be adjusted freely.

User-Friendly Interface: Equipped with a user-friendly interface, the machine enables easy operation and intuitive control of slicing parameters, ensuring efficient setup and minimizing the learning curve for operators.

Reliable Safety Features: The machine is equipped with safety features such as emergency stop buttons, protective covers, and sensors to ensure operator safety during operation and reduce the risk of accidents.

Robust Construction: Built with a sturdy and durable frame, the ultrasonic nonwoven filter bag dust bag slicing machine is designed for long-term reliability and can withstand heavy usage in industrial environments.

MACHINE CHARACTERISTICS:

1. the whole machine is made of aluminum alloy structure, which is oxidized and sturdy without rust.

2. PLC program control, servo motor drive, human-machine interface operation, high stability, excellent performance, no material can automatically stop. If there is any problem during production, the human-machine interface will automatically show the place for troubleshooting, saving time and making the production capacity more efficient.

3. Maximum diameter of filter media: 1000mm.

4. Maximum working width of filter media: 720mm.

5. Width of finished product: 675mm.

6. Side fusion and end fusion can be freely selected.

7. Length of finished products (bags) can be freely selected.

8. 4 to 6 sets of ultrasonic synchronous welding.

| Machine size | 6400 (L) *1650 (W) *2100 (H) mm |

| Power supply | 1P 220V 3P 380V |

| Air pressure | 0.6-0.7MPa |

| Production capacity | Melt bottom slicing 15PCS/min |

| Power consumption | 7.5KW |

Our advantage

SCALE ADVANCED PRODUCTIVITY

The company has gathered a group of experts who have been engaged

in production site maintenance, operation control, and machine

debugging for many years. With experienced staff. For long-term

operation of industrial equipment due to disturbance Difficulties

and frequent detects, production and design put forward solutions,

let the solutiongs in the design Stages are field-tested to

maximize the effectiveness of the solution at the lowest cost.

PROFESSIONAL R&D TEAM

At the beginning of its establishment, Xinlong started to cultivate

a professional R&D technical team, always pay attention to the

latest development in the field of non-woven fabrics, and closely

track new technologies at home and abroad. The R&D team has

been accumulating for many years and has maintained professinoal

sensitivity.

EQUIPMENT MANUFACTURING TEAM

The company has gathered a group of staff with many years of rich

exerience. Aiming at some difficulties and frequent defects that

have caused long-term disturbance to the operation of equipment in

the industry, production and design propose solutions, allowing the

solution to undergo on-site inspection during the design stage, so

that the solution can achieve the strongest effectiveness and the

lowest cost.

Xinlong brand advantage:

Choosing our Xinlong brand air filter bag machinery and equipment means choosing high efficiency and quality.

Our products meet the highest standards and provide excellent results.

To provide your foreign business partners with the best air filter bag production technology. With our machines, customers can improve their productivity.

Excellent performance: high productivity, able to quickly complete the production process of non-woven bags, and produce a large number of products in a unit time to meet the needs of mass production.

Precision molding: Non-woven fabrics can be accurately cut, sewn or hot-pressed into specified shapes and sizes to ensure the uniform specifications of each bag.

Diversified production: it can adapt to non-woven materials of different styles, sizes and thicknesses, and produce various types of non-woven bags, such as handbags and backpacks.

Stable operation: the machine maintains stable performance during long-term operation, with low failure rate and reduced downtime and maintenance time. Made of high-quality materials, it is durable and will serve you for a long time.

Convenient operation: intelligent operation, simple operation, automatic control, worry-free and labor-saving Friendly man-machine interface, simple and convenient operation, easy for workers to get started quickly and skillfully.

Energy-saving characteristics: it has certain energy-saving design, reducing energy consumption and production cost.

Reliable quality: the manufactured non-woven bag is durable and sealed firmly, and can bear certain weight and wear.

Customized design: meet your personalized needs in different scenarios.