Active Member

|

[China]

Address: Building 13, Maker Town, Liuxian Avenue, Nanshan District, Shenzhen

Contact name:Roc Chow

ShenZhen Vector Technology Co., Ltd. |

|

Internal Planning Position 7.5kw 380V AC Servo Drives System For 3C Electronic Equipment

Vector Tech. Focus on Servo system for more than 17 years. Focusing on industrial automation products

with independent intellectual property rights, we are positioned to serve high end equipment manufacturers

and provide overall solutions for customers in market segments. To become the world's leading provider of

industrial automation products and solutions. Independently developed products include servo drive, motion

controller, human-machine interface, servo motor, etc.,

Products Description

| Products | 7.5kw 380V AC Servo Drives System |

| Brand | Vector |

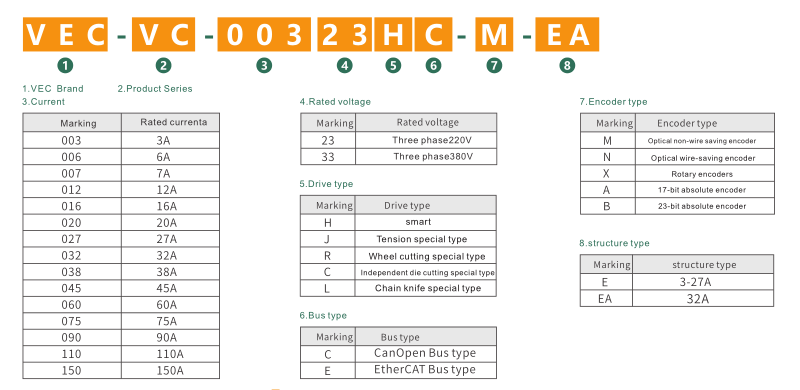

| Model No. | VEC-VC-02733HC-M-E/180ME-7R515A33-MF2C |

| Power | 7.5KW |

| Voltage | 380V |

| Phase | Three Phase |

| Rated Speed | 1500 rpm |

| Rated Current | 27.6A |

| Rated Torgue | 48 N.m |

| Communication Protocols | Modbus/CANopen/EtherCAT |

| Voltage | Control Mode | Single-phase / three-phase full-controlled rectification SVPWM modulation |

| Encoder | Encoder Feedback | 2500 pulse incremental + Hall encoder; 2500 pulse incremental; 17bit Tamagawa absolute encoder; 23bit Tamagawa absolute encoder; 24bit Nikon absolute encoder; |

| Pulse Command Input | Pulse Type | Differential input,Open collector |

| Frequency Range | Differential input:0-500kHz,pulse width greater than 1us Open collector: 0-300kHz,pulse width greater than 2.5us | |

| Pulse Mode | pulse + direction; AB pluses; CW+CCW; | |

| Analog Input | Voltage Range | -10V to 10V |

| Input Impedance | 10kΩ | |

| Maximum Frequency | 1.5kHz | |

| DI/DO Interface Type | NPN/PNP | |

| Communication | Modbus/CANopen/EtherCAT | |

| Position Mode | Command Input Method | Pulse Command Internal Planning Position Plan by target position, speed, acceleration and deceleration time Trapezoidal speed curve Cubic speed curve Absolute / relative command mode |

| Instruction Smoothing Mode | Low Pass Filtering / Median Filtering | |

| Electronic Gear Ratio | N/M;(M=1~2147483647,N=1~2147483647) | |

| Torque Limit | Internal Torque Limit / Analog Torque Limit | |

| Feedforward Compensation | Speed Feedforward / Torque Feedforward | |

| Torque Compensation | Fixed Torque Compensation / Analog Torque Compensation / Automatic Torque Compensation; | |

| Speed Contol Mode | Command Input Type | Pulse Frequency / Analog / Internal Planning Speed |

| Speed Control Range | 1~max speed | |

| Bandwidth | 1kHz | |

| Torque Limit | Internal Torque Limit / Analog Torque Limit | |

| Instruction Smoothing Mode | Low Pass Filtering / Median Filtering | |

| Feedforward Compensation | Torque feedforward | |

| Torque Compensation | Fixed Torque Compensation / Analog Torque Compensation / Automatic Torque Compensation; | |

| Torque Control Mode | Command Input Type | Internal Torque Reference / Analog Control Torque |

| Torque Compensation | Fixed Torque Compensation / Analog Torque Compensation / Automatic Torque Compensation; | |

| Speed Limit | Internal Speed Limit / Analog Speed Limit | |

Details about a Servo Drive, how to select the Servo drive model and do installation?

| Key Name | Key function |

| Mode | mode switch, return to the previous menu |

| ▲(add) | increase flashing bit value of the LED digital tube |

| ▼(dec) | Decrease flashing digit value of the LED digital tube |

| ◄◄(shift) | Moves the blinking LED tube to the left; checks the high value of

data longer than 5 bits; Fault reset;execute Fn function |

| SET | read/write parameter values |

● Install the driver on a dry and sturdy platform. Maintain good ventilation and

heat dissipation during installation and maintain good grounding.

● Please install in the specified direction to avoid malfunction.

● When installing, please ensure that the servo driver is kept at a specified

distance from the inner surface of the cabinet and other machines, otherwise it may cause fire or malfunction.

● When installing, do not block the suction and exhaust ports, and do not allow foreign objects inside the

product to enter, otherwise it may cause malfunction or fire due to aging of internal components.

● Do not place heavy objects on or under this product as this may result in injury.

● Please install in the following environment:

1.places without direct sunlight;

2.Locations where the ambient temperature is in the range of 0 ° C to 55 ° C;

3.Relative humidity in the range of 0% to 95%, and no condensation;

4.Locations free of water droplets, vapors, dust and oily dust;

5.Locations where there is no high heat device;

6.Non-corrosive, flammable gas and liquid sites;

7.It is not easy to splash water, oil and medicine;

8.places that are not exposed to radioactive radiation;

9.Strong and vibration-free places;

10.Locations where there is no electromagnetic noise interference.

| Installation Environment Requirements | Atmospheric Pressure | 86~106kPa |

| Mbient Humidity | 0~55℃ | |

| Ambient Temperature | 0~90%RH | |

| IP Rating | IP20 | |

| Vibration | 0~4.9m/s^2 |

Servo motor description - How to select the servo motor

Delivery Time and Shipping Way

| Quantity | 1-5 kits | 50-100 kits | 200-500 kits |

| Delivery time | Within 3 days | 5-10 days | 15-25 days |

1. For small order we always can delivery out within 1 week.

2. Our products can be shippied via Air, Land or Sea.

Contact Us