JIANGSU LIANZHONG METAL PRODUCTS (GROUP) CO., LTD |

|

Verified Suppliers

|

|

The large carbon fiber curing molding high temperature and high pressure tank is a state-of-the-art equipment used in the manufacturing industry. It is specifically designed for the production of high-quality carbon fiber products.

This tank is made from carbon fiber, a lightweight and high-strength material known for its exceptional mechanical properties. The use of carbon fiber ensures the tank's durability and resistance to high temperatures and pressures.

The tank is designed to provide a controlled environment for the curing and molding process of carbon fiber products. It is equipped with advanced temperature and pressure control systems to ensure precise and consistent conditions during the production process.

The high temperature and high pressure capability of the tank allow for the efficient curing and molding of carbon fiber composites. This results in products with excellent strength-to-weight ratio, stiffness, and impact resistance.

The large size of the tank allows for the production of large-scale carbon fiber products, such as aerospace components, automotive parts, and sporting goods. The tank's spacious interior provides ample space for the placement of molds and ensures uniform heat distribution during the curing process.

Overall, the large carbon fiber curing molding high temperature and high pressure tank is an essential tool for manufacturers in the carbon fiber industry. Its advanced features and capabilities enable the production of high-quality carbon fiber products that meet the stringent requirements of various industries.

| TYPE | MODEL | VALID CAPACITY (m³) | WORKING PRESSURE (Mpa) | DIMENSIONS (mm) |

| LPG Tank ( Ground ) | WG 1.77-1400-005 | 5 | 1.77 | 1400*2750 |

| WG 1.77-1400-010 | 10 | 1.77 | 1400*5980 | |

| WG 1.77-1400-010 | 10 | 1.77 | 1600*4400 | |

| WG 1.77-1400-020 | 20 | 1.77 | 2000*5650 | |

| WG 1.77-1400-025 | 25 | 1.77 | 2200*5800 | |

| WG 1.77-1400-030 | 30 | 1.77 | 2200*7100 | |

| WG 1.77-1400-040 | 40 | 1.77 | 2600*6600 | |

| WG 1.77-1400-050 | 50 | 1.77 | 2600*8500 | |

| WG 1.77-1400-060 | 60 | 1.77 | 2600*10360 | |

| WG 1.77-1400-100 | 100 | 1.77 | 3000*13200 | |

| WG 1.77-1400-120 | 120 | 1.77 | 3600*10500 | |

| WG 1.77-1400-150 | 150 | 1.77 | 3600*13500 | |

| WG 1.77-1400-200 | 200 | 1.77 | 3800*16300 | |

| LPG Tank (UnderGround ) | WG 1.77-1400-005 | 5 | 1.77 | 1400*2750 |

| WG 1.77-1400-010 | 10 | 1.77 | 1600*4400 | |

| WG 1.77-1400-025 | 25 | 1.77 | 2200*5770 | |

| WG 1.77-1400-030 | 30 | 1.77 | 2200*7100 | |

| WG 1.77-1400-050 | 50 | 1.77 | 2600*8500 | |

| WG 1.77-1400-060 | 60 | 1.77 | 2800*8740 | |

| WG 1.77-1400-100 | 100 | 1.77 | 3000*13200 |

Details technical

Specification

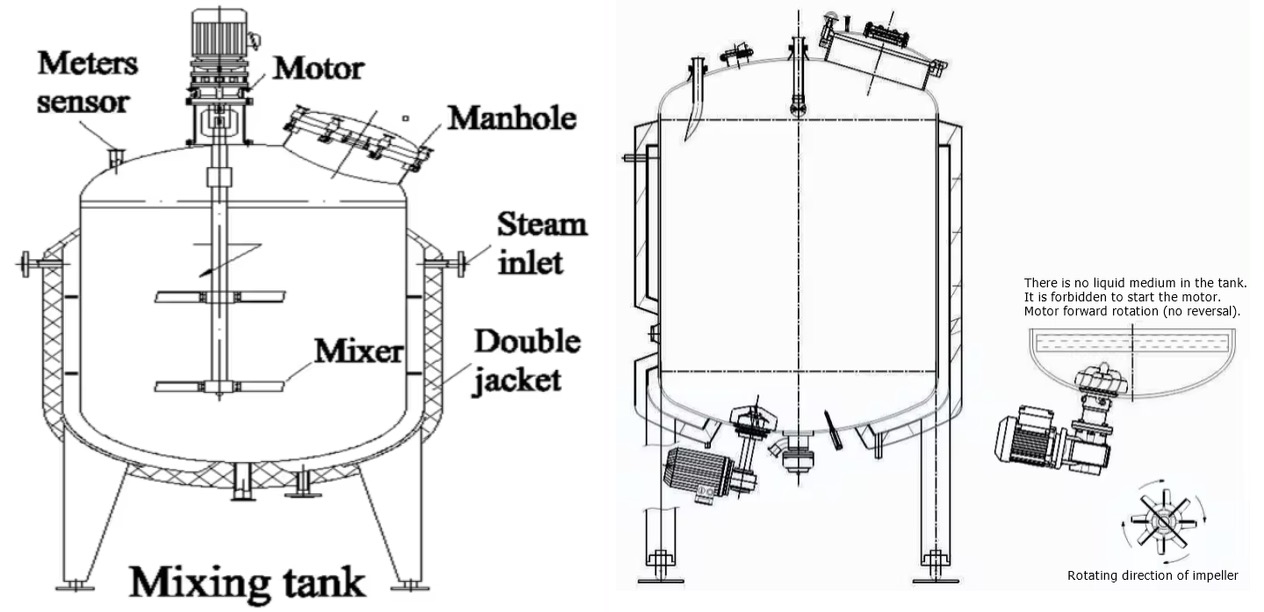

1. Capacity:50L-50000L

2. Materical:SS304 and SS316

3. Single layer/Double layers/Three layers

4. Polished inside and outside

5. Quick open manhole

6. Agitator Power:0.25-15KW

Application of Resin plant

Chemical Machine Resin Plant is the key equipment for producing all

kinds of resins, such as Alkyd resin, Acrylic resin, PET resin,

epoxy resins, ABS resins, Polyester resin, Unsaturated polyester

resin, , Amino resin, curing agent. PVA Emulsion/Acrylic

emulsion/polymer emulsion/water base PU

The whole set of equipment includes reactor, vertical fractionating

column, horizontal condenser, water storage tank, oil spill tank

and piping (dilution kettle). All parts of the equipment that

contact with the material are all made by stainless steel.

Detailed Photos

Packaging & Shipping

More Products

FAQ

Q1: How long is the warranty of the AAC production line?

A1: Our warranty period is one year generally.

Q2: Can l visit your factory?

A2:Yes. We warmly welcome you to visit our factory.

We will take you to our customer site to have a real look.

Q3: Do you provide equipment operation training?

A3:Yes. We can send professional engineers to the working site for

installation, adjustment,and operation training. All of our

engineers have passports.

Q4: Do you provide whole AAC production line flow chart?

A4:Yes. Our experienced engineers are specialized in designing

process flow for various project.

Q5: Can you test our samples?

A5:Yes. You can send your samples to us for test and analysis.

Q6. How about price?

A6:Yes, we are factory and are able to give you the lowest price

than market one and we have a policy that “for saving time and

absolutely honest business attitude, we quote as low as possible

for any customer, and discount can be given according to quantity.

contact us.