JIANGSU LIANZHONG METAL PRODUCTS (GROUP) CO., LTD |

|

Verified Suppliers

|

|

Vacuum Low-Temperature Stirring Drying Machine For Ethyl Formate Processing

Based on the manufacture technology of vacuum dryers in China, ZPG

Rotary Vacuum Rake Dryer is our improved products for drying

materials shaped like slurry, paste, grain, powder and fibre. The

drive system adopts column gear reducer which performs firm and

wear well. The driving shaft is stainless steel thickened solid

type. The rake teeth is made of high strength stainless steel,

which guarantees the stable operation under all kind of odious

conditions. Inside the shell can be added two or four impact rods

for the purpose of high speed drying and smashing. The heating

medium can be steam, heat conducting oil and hot water.

Features:

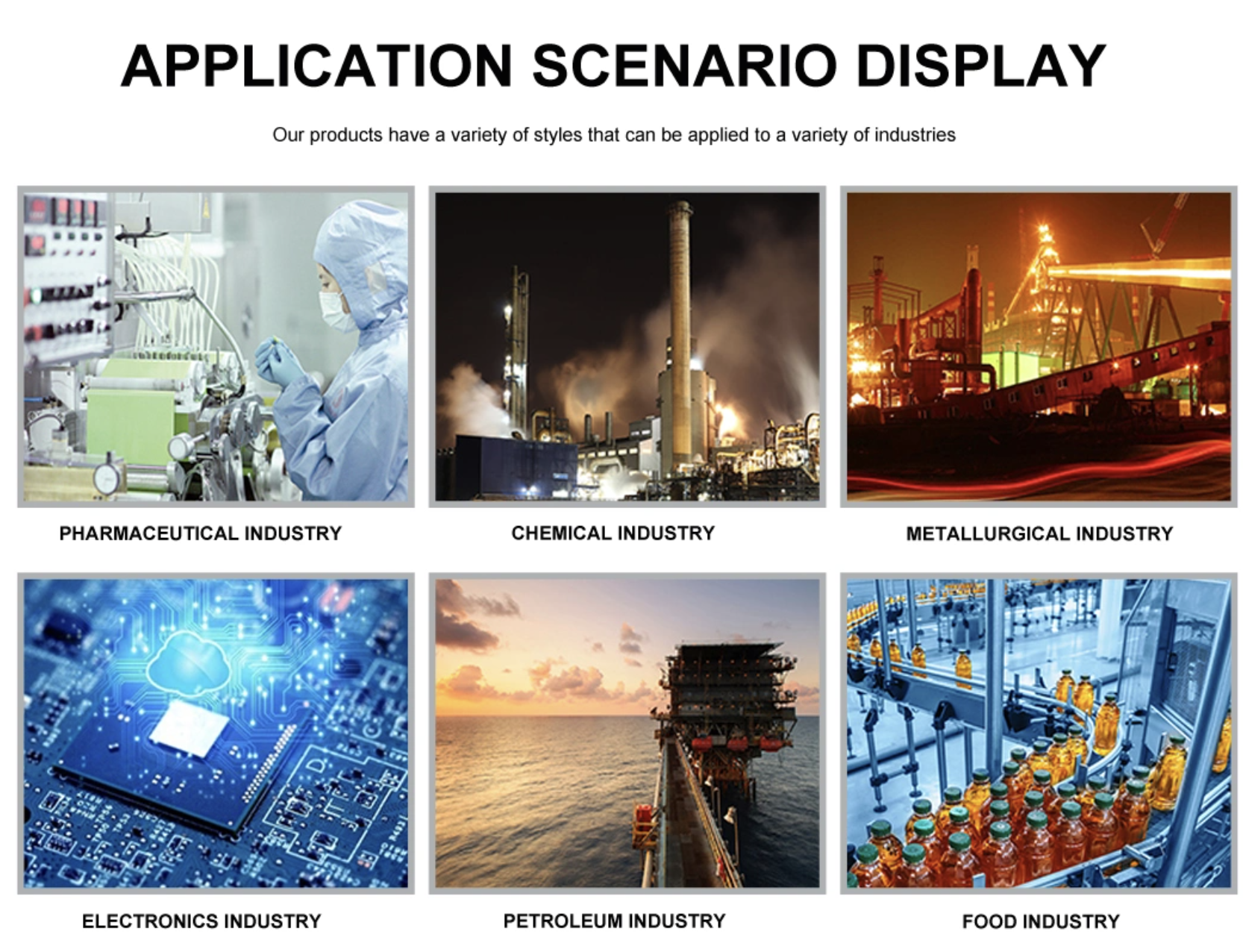

1. Wide application range, high drying speed. Because the rake

vacuum pump use jacket to heat and high vacuum to vent gases. So it

can almost apply for all materials with different quality and

different shape. It is especially suitable for flamable and

oxidable materials.

2. High quality products. The rake teeth turns in two directions

constantly, and the material is well mixed.

3. Small steam consumption.

4. Easy operation. It can be used to reclaim volatilizable gases,

and reduce environment pollution.

Service:

pre-sale service

We Invite customers to visit our company and communicate on

technical requirements face to face.

sale service

Responsible for debugging the equipment according to customers'

requirements of various technical data. Our engineers will train

our customers about equipment features and operation key points to

make sure the equipment running in the best condition.

after-sale service

We provide installation, debugging, maintenance, training and other

services; Provide relevant technical data, equipment, software and

related GMP certification materials;Set up after-sales service

hotline, and arrange personnel to visit customers every year to

know more customer needs,like customer operation problems in the

process of production equipment.