Jiangsu Sankon Building Materials Technology Co., Ltd. |

|

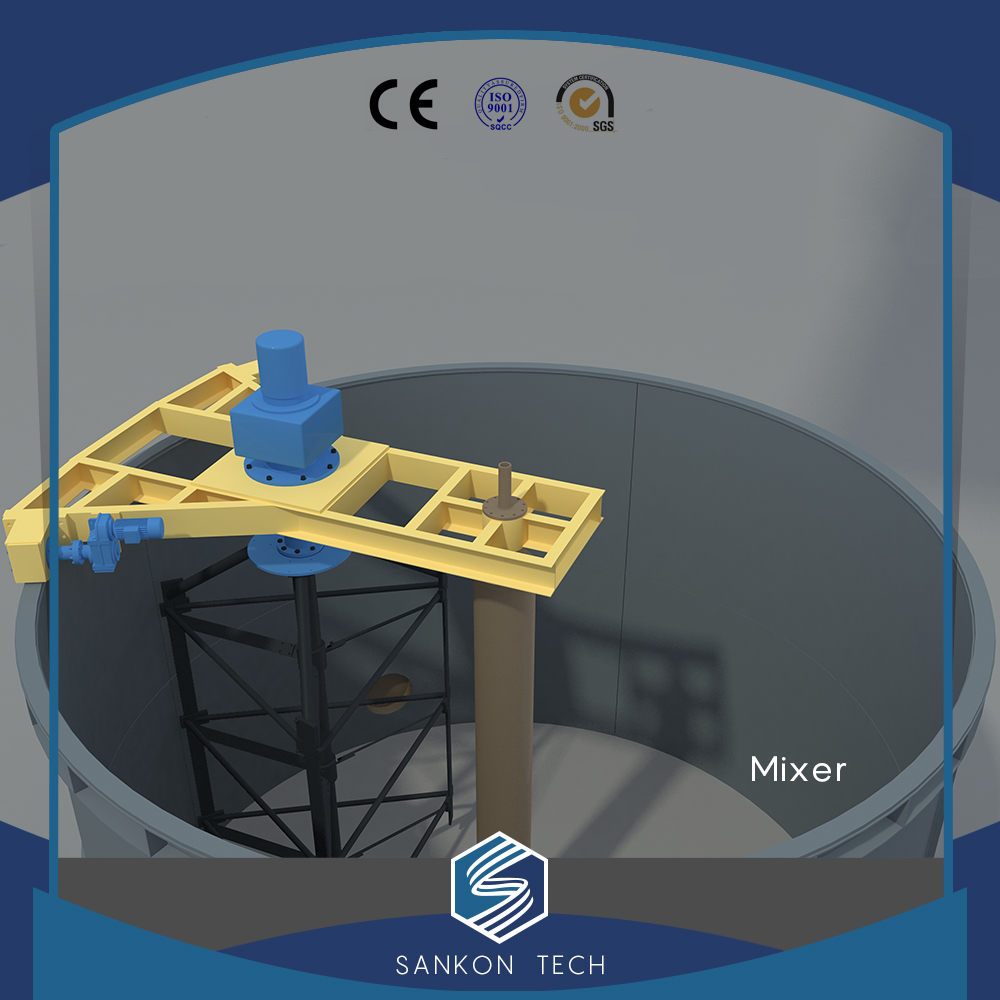

Slurry Mixer

Application:

The Six-cube Slurry Mixer (refer to the photo and drawing) is especially used to mix the lime, Steam Aerated concrete arenaceous powder, water completely to form slurry.

Technical Parameter:

1.Max size

L:3980 mm W:3000 mm H:3108mm

2. Weight:~2500kg

3. Helical gear reducer

a) Type:CRM147-84.5-Y-11-V1

b) Motor:Y160M-4 power 11KW rotate speed:1460r/min

c) speed ratio:i=84.5

4. Mixing speed:17.2r/min

Structure:

The mixer is composed of helical gear reducer, channel steel frame, and paddle wheel, etc.

Channel steel frame is made of 20# channel

It is equipped with helical gear reducer.

Paddle wheel is made of steel pipe, plate and mixer shaft.

Working principle:

The twenty-cube mortar mixer is used to mix the lime, Steam Aerated arenaceous powder, water completely to form slurry. Mixer is driven by helical gear reducer, which rotate counterclockwise from up to down.

Pilot running and debugging:

1.Pilot running

Reducer can rotate without abnormalities, no jamming and no weird noise. Mixer can rotate in balance, no inclining, no swaying.

2.Adjust

a.If the reducer is jammed or there is weird noise, please disassembly and then check the pad of its bearing pedestal.

b.If the mixer is inclining or swaying, please try to debug with a pad between bearing pedestal and beam frame.

Maintenance and repair:

1.Maintenance

a.Please make sure that there is no slurry in the basin before stop working. Otherwise, the mixer may be damaged because of slurry sedimentation.

b.Please check lubricating oil of the reducer and to fill timely. Normally, lubricating oil is expected to be changed after six months.

c.To clean the mixer and its basin after every day’s work.

2.Repair

Please check all fasteners to avoid any possible loose and change worn parts.

Cautions:

Please turn off power and stop mixing before you start to clean up the mixer.