Jiangsu Sankon Building Materials Technology Co., Ltd. |

|

Autoclaved aerated concrete (AAC)is the material of choice for building applications, such as residential, commercial, industrial and agricultural buildings, hotels, schools and hospitals, etc., - an excellent building material for all climatic conditions. It is used for all walls, external or internal, loadbearing or non-loadbearing walls, basement walls, infill walls to framed structures, party walls, fire break walls, etc.

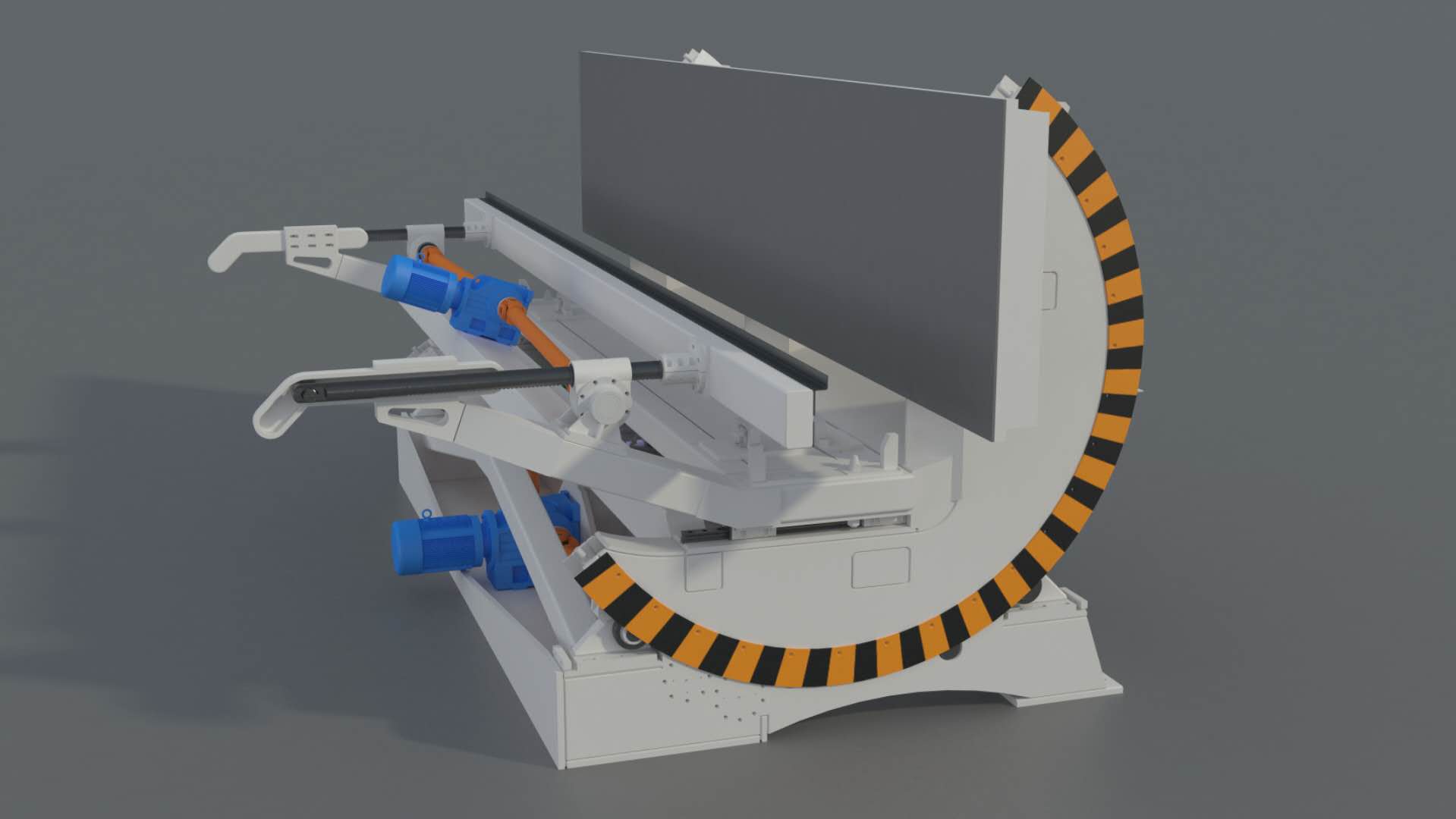

Automatic AAC Block Making Machine Servo Motor Control

Aerated concrete brick (light brick ) is the light and porous building material. It has lightweight keeping temperature can't burn and other advantages.it can be made into many kinds of bricks(for example:600×200×100,80×80×180,240×115×53,600×200×125), they could be used industry building and common building, they are more and more popular in the world.in the future,they will replace the Clay brick completely.

Areated concrete common conception

Common concrete density is usually 1600-2400kg/m3,but Created concrete are 500kg/m3,600kg/m3,700kg/m3.It has not the big grain,main use silicon material (for example:coal ash,sand,stone dust and others ),through making the material small for example

sand,they can be used directly if has enough degree of small (for example coal ash.Mixing calcium material lime cement water to a special slop,then add the aluminum dust and the additive.Make the aluminum dust and the special slop have a Chemical reflect.then

produce Hydrogen to make the concrete slop to expanding or swell,foam.Next,put them into the curing room to concreting cutting steaming curing,last,there will bacome the light brick,the porous rate is 70-80%.

| Automation Grade | Automatic |

| Brick Material | Quick Lime |

| Production Capacity | 50,000-350,000 blocks per day |

| Power Consumption | 400 - 1000 kW |

| Country of Origin | Made in India |

| Voltage Range | 320-380 V |

Advantages

1) light weight

Areated concrete density is usually 400-700kg/m3,(according the market in produce ),same as 1/3 of clay brick and 1/5 common concrete.So use the Light brick can reduce the weight of the build more,and also reduce the beam of roof and pillar press best.then you can see,it can save the material and cost,it also fighting shaking.

2) keeping temperature

It has many porous,the delivery hearting coefficient is 0.9-0.22W/(mk),the same as 1/4 or 1/5 of clay brick,so it is best materials now in the world. Also many kinds raw material,have lowest wasteMain Material:coal ash sand waste mine material coal stone,stone dust and other silicon materials.

Company introduction:

SANKON Building Materials Technology Co. is a one stop solutions provider for autoclaved aerated concrete (AAC) production equipment including complete AAC production lines. We employ a team of experts with more than 20 years of industry experience to drive our innovative efforts and create highly efficient building material production equipment. Using highly automated production machinery, SANKON is able to produce more than 9 thousand tons of equipment each year to satisfy our customers all over the world. Contact us today to learn more about our outstanding AAC production machinery.

If you are interested in any product of our company, please feel free to contact me. Any enquiry would get our professional and prompt reply!

JIANGSU SANKON BUILDING MATERIALS TECHNOLOGY CO.,LTD.

Add.: No. 31, Xinxi Road, Chuanjiang Town, Xinbei District, Changzhou City, Jiangsu Province

Contact Person: Rita

Tel.: +86-519-83996829