New Release Automatic BGA Rework Station WDS850 Optical Alignment

Motherboard Repair Tools For Mobile Computer Laptop

Application of WDS-850 automatic bga rework station :

→Laptop / Notebook/ Computer motherboard

repair.

→ Playstation / XBOX 360 and other game console repair.

→ Mobile ECU Car motherboard repair.

→ TV / Video / ipad mainboard repair.

→ SMD/ SMT / IC / VGA BGA rework .

Power | Ac220v±10%,50/60hz |

Total power | 7600W |

Heater power | Upper heater max1200W |

Down heater max1200W |

IR max5000w |

Pcb position way | V-groove +universal jigs+laser position |

Temperature control | K-sensor closed-loopindependent temperature measurement |

Electronic material | High sensitive touch screen+Hign sensitive temp control module+plc+server driver+server motor |

PCB size | Max610×480mm Min 10×10 mm |

Chip size | Max120×120mm Min 0.5×0.5mm |

Pcb thickness | 0.3-5mm |

Alignment system | Optical prism+HD industry camera |

Mount accuracy | ±0.01mm |

Temperature interface | 5pcs |

Max mount load | 150G |

Tin point monitoring | Optional external camera to monitor the solder ball melting process

during the soldering process |

Feeding device | Auto receiving and feeding device |

Dimensions | L810×W790×H1580mm |

Weight | About 210kg |

Other features | 5axis electric motion control |

PRODUCT SPECIFICATIONS

♦ 5 working modes

♦ 15’’ HD LCD monitor

♦ 7’’ HD touch screen

♦ CCD color optical alignment system

♦ Laser light for positioning

♦ Infrared preheat tubes + hot air heating areas

♦ HD camera comes in & out automatically by button

♦ Temperature accuracy within ±1℃

♦ Mounting precision within ±0.01mm

♦ Repair success rate: 99% +

1. Auto feed chips,auto pick up chips,auto blowing chips.

2. Hot air head and mounting head integration design, with auto

soldering and desoldering functions.

3. Upper heaters adopt hot air system,heating faster,temperature

evenness,cooling faster.(the temperature can be up to 50 to 80 centigrade)It can better meet technological requirements about

lead-free soldering.Lower heaters adopt Hot air & IR mix heating. IR acts on the heating area directly; in the

meanwhile, hot air works. They interact to heat quickly, and

keep temperature even. (heating-up speed is up to 10 centigrade per

minute.

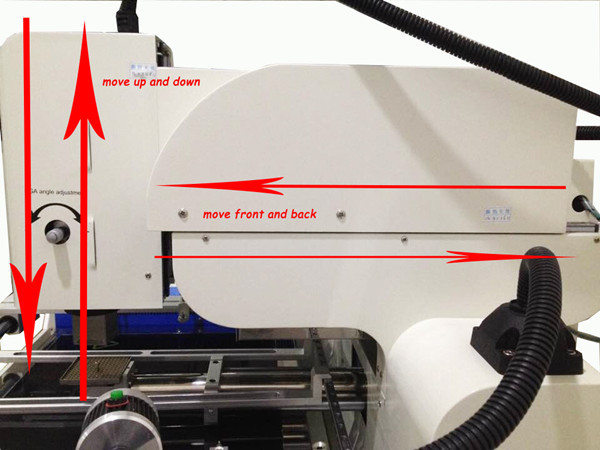

4. Independent 3 heaters, upper and lower heaters can realize move

synchronously and automatically,can reach IR every position.Lower heater zone can remove up and down,support PCB

board. bottom pre-heating area along X/Y axis. Lower heater can move up/down and support PCB,auto-controlled by motors.

It can realize the upper and lower heater able to move towards target BGA, without moving PCB.

5. PCB board adopts high accuracy slider to make sure the mount

precision of BGA and PCB. Unique bottom preheating table made of Germany-imported good

quality heating materials plated IR tube & constant temperature glass anti-dazzle (heat-resist up to 1800 C),

pre-heating area up to 500*420mm.

6. Preheating table, clamping device and cooling system can move

integrally in X axis that make PCB locating &desoldering safer and conveniently.

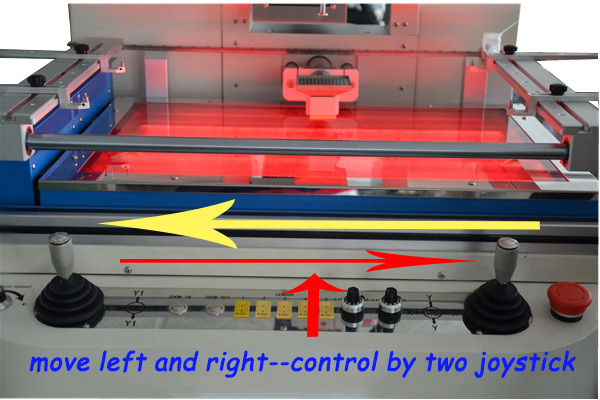

7. X and Y axis adopt motor automatic control moving way to make

the alignment faster and more convenient,make the most use of the equipment space,realization of repairing large area

PCB with a smaller volume of equipment.TheMax.plate size can reach 650*610mm,no repair dead corner.

8. Double rocker control the camera and upper and lower heating

platform to make sure the alignment precision accuracy.

9. Inbuilt vacuum pump, rotate 360 in angel; fine-adjusting

mounting suction nozzle.

10. Suction nozzle can detect BGA pickup and mounting height

automatically with pressure controllable within 10grams; zero pressure available to smaller BGA pickup and mounting.

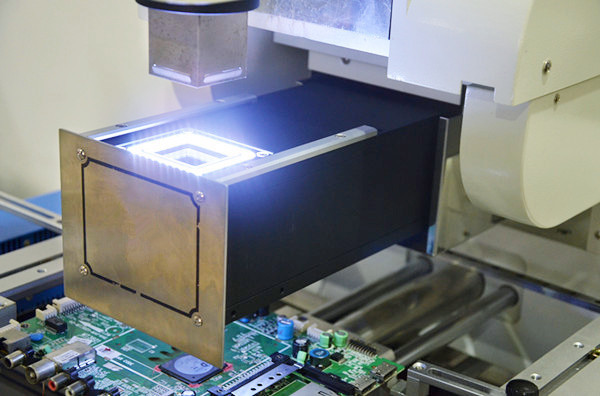

11. Color high-resolution optical vision system, movable by hand in

X/Y axis, with split vision, zoom in and fine-adjusting functions, aberration distinguish device included, auto-focus,

software operation, 22x optical zoom; reworkable max. BGA size 80*80MM;

12. With 10 segments of temperature up (down) and 10 segments of

constant temperature control,can save many segments of temperature.analyze the temperature parameter curves on the

touch screen.

13. Many sizes of alloy nozzle, easy for replacement; can locate at

all angle.

14. With 5 thermocouple ports, can real-time detect and analyze

temperatures at multipoint.

15. With a solid operation display function to make the temperature

control more reliable.

16. It can generate SMT standard temperature removing curve

automatically in different regions and different environment temperature,don’t need to set curves manually, anybody can use it

even without experience, realize machine intelligence

17. With the camera that can observe the melting point of solder

side, it is convenient to determine the curve (this feature

is optional items).

Packing Details

Customer Feedback