Shandong Weike CNC Machinery Co. LTD |

|

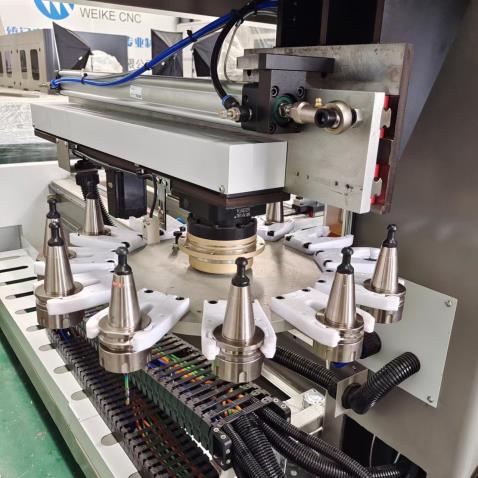

The 4 Axes CNC Machining Center, It is a Gantry Frame machining center with 4-axis milling motor of 9 KW with tool turret of 12 places. At this large profile section, width 550 mm x heigth 200 mm, we are albe to measure, drill, tap, mill and saw.

1. Equipment Features

● The machine can realize the clamping of raw materials at one time, and according to the processing needs, it can complete the cutting, milling end face tenon, milling key hole slot, running trough, air pressure balance hole, installation hole and other multi-process processing to meet customers' requirements for doors, windows, curtain walls, and sun rooms. , Personalized customization of industrial aluminum profiles.For a variety of aluminum, copper, PVC, industrial profiles and other complex parts processing.

● The machine is equipped with an industrial numerical control system, dedicated CAD-CAM editing software for three-dimensional modeling display, automatic tool setting, which can optimize the travel path. It can complete continuous automatic milling of different specifications and sizes of profiles, with powerful functions. CAD drawings can be imported into the system for convenient and simple, and can be equivalent to domestic and foreign doors, windows, and curtain wall system software.

● It is suitable for the processing of complex parts such as various aluminum, copper, PVC, industrial profiles, building curtain walls, and sun rooms.

● The single-arm frame structure with moving beam and moving column is adopted, which makes the operation more stable and improves the processing rigidity of the machine tool.

● High-quality bus servo motors, ball screws, linear guides and bearings are used to ensure that the equipment has high processing accuracy, high stability and reliability. The feed movement is pre-stretched to ensure the stability of the machining accuracy.

| Product Parameter | |

| Tools magazine | 12 Milling drilling bits |

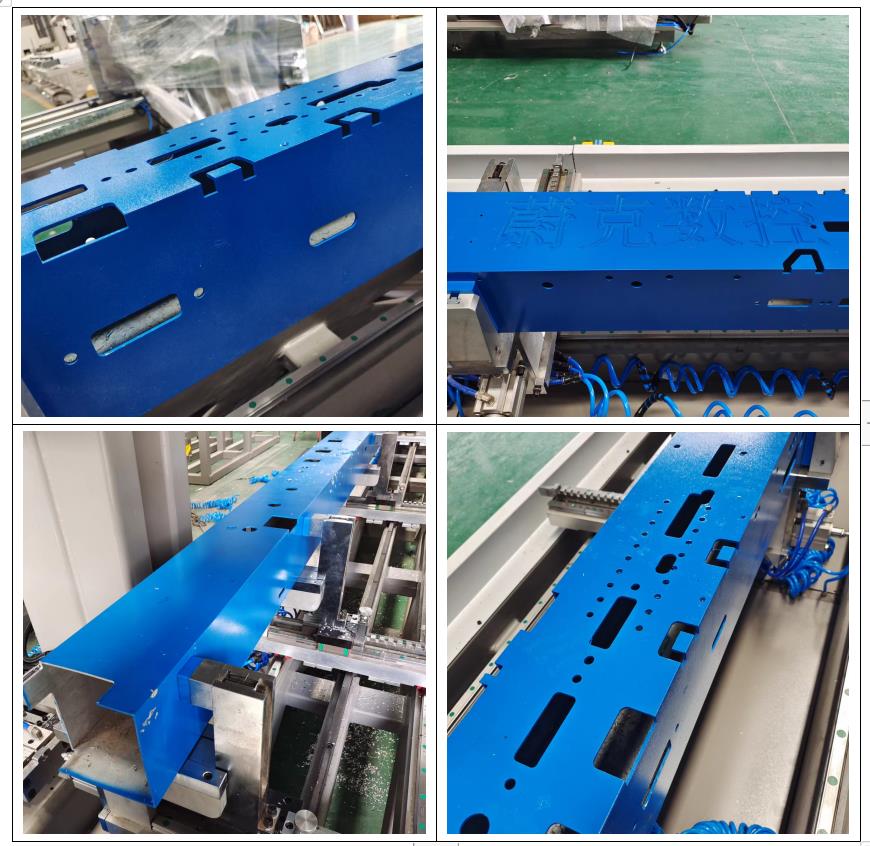

| Table structure | Heavy duty welded machine body with clamping tooling on it special for clamping aluminum profile |

| Working Size | X/Y/Z> 6500*400*300mm |

| Maximum speed | 24000/min |

| Processing length | 6500mm |

| Processing width | 400mm |

| Processing height | 300mm |

| Control System | Germany HANS PA industrial CNC system is equipped with professional CAD-CAM programming software |

| Lubrication system | Auto lubrication pump |

| Tool setting | Automatic tool setting |

| Electric Components | French Schneider AC contactor, Taiwan Airtac electromagnetic valve |

| Working voltage | 380V 3Ph 50Hz |

| Size | 9500*2500*2800mm |

| Weight | 4500kg (more or less) |

| Machine function | End milling, lock holes, water slots, install hole... Auto tool changer Auto tool setting |

2.Mechanical details and after working samples

1.Controller:

Germany HANS PA CNC system

Match CAM programming software special for aluminum profile area

2.Spindle:

Italy Olispeed fast milling head is air-cooled, operates with 9 kW 24,000 rpm

3.Tool Magazine

ISO30 tool holder and has 12-tool changing magazine

4.Clamps:

Designed clamps approved patent can adjust to suitable different width and height profile.

5.Holes sample after work

3.Other products

4. Our services

1.Provide free training when come to factory study.

2. If need engineer go to oversea training: Client afford transportation and accommodation, Engineer salary is 100USD/Day.

Because of Covid-19, we provide:

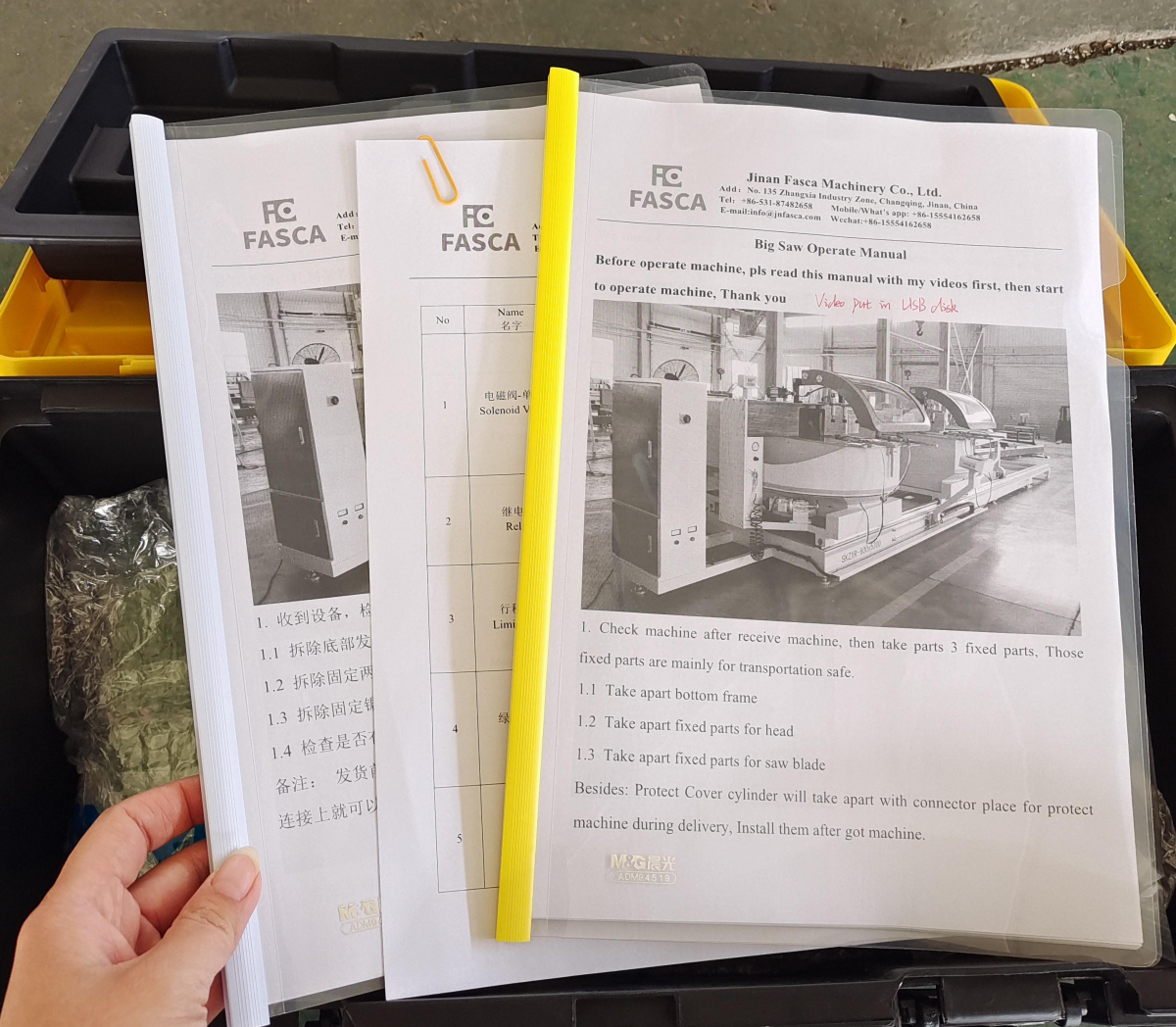

1. Before delivery: Machine operate manual, program software user manual and English videos.

2. Before delivery: Face to face video training online between your operator and our engineer.

3. After delivery: Will video guild you how to install and adjust machine. Also we can online control your machine to show you how to work.

Machine Operate Manual Will Be Provided

Machine Operate Video Will Be Provided

5.Packaging Details

1. Inside is plastic film.

2. Under the equipment is the iron tray fixed, or choose

wooden box packing

3. Can also be based on customer needs for

packaging QingDao Port

6. Any Questions?

1. Why is it called 4 axes machining centre ? What are the functions?

2. What are the advantages of 4 axes over 3 axes?

3. Are there training instructions?

4. How long is the warranty?

5. Can the 4 axes be customized according to my needs?

6. What brand are the accessories?

If you also have these questions, you can contact me for more

details.

WEIKE provide machine

More important is provide

Solutions