BETTER CONVEY AUTOMATIC EQUIPMENT CO., LTD. |

|

High Speed Swivel Sorters for Parcel Sorting at Airport

Technical data

Pivot wheel sorters are typically belt driven, and sort using two sets of wheels that pivot separately and in sequence, at each diverter station. Pivot wheel sorters run up to 75 cartons per minute.

Solutions has a strong history of Pivot Wheel Sorter installations across many industries. Let us help you achieve new levels of automated sortation accuracy.

Specification of Swivel Wheel Sorter

| Name | Swivel Wheel Sorter |

| Voltage | 48VDC / 380V / 415V, 220V / 380V / 415VAC |

| Dimension(L*W*H) | 610mm*688mm*800mm or Customized |

| Material | Stainless Steel/Carbon Steel |

| Material Feature | Fire Resistant |

| Structure | Line Wheel Diverter |

| Power | 750W or Customized |

| Width | 480, 580, 680, 780,980,1080mm |

| Length | 510mm + 100 x numbers of module |

| Sorting capacity | 4,000 PPH or Customized |

| diverting angle | 30-45-60-90degree |

| Diverting time | 0.24s |

| Sorting orientation: | forward, right and left |

| Min. parcel size | 100 x 100 x 10mm |

| Max. parcel size | 1200 x 800 x 800mm |

| Loading weight | 0.2-40kg |

| Loading size | max. 800mm x 1,200mm x 800mm |

| min. 100mm x 100mm x 10mm | |

| Conveying Speed | 60~150m/min(Adjustable) |

| Noise | less than 75dB |

| Warranty | 1 Year |

| After-sales Service Provided | Free spare parts, Engineers available to service machinery overseas |

Wheel Sorter Catalogue

| 1200W | L1230*W1280*H600 | 60-120 |

| 1200W | L1030*W1280*H600 | 60-120 |

| 1000W | L1230*W1080*H600 | 60-120 |

| 1000W | L1030*W1080*H600 | 60-120 |

| 800W | L1030*W880*H600 | 60-120 |

| 800W | L830*W880*H600 | 60-120 |

| 600W | L630*W680*H600 | 60-120 |

Working environment

■ Environment temperature: -50 ~ 45℃

■ Relative humidity: 20 ~ 95%

■ The site does not allow the medium with explosive danger, and the surrounding medium should not contain corrosion metal and destroying insulation gas and conductive medium.

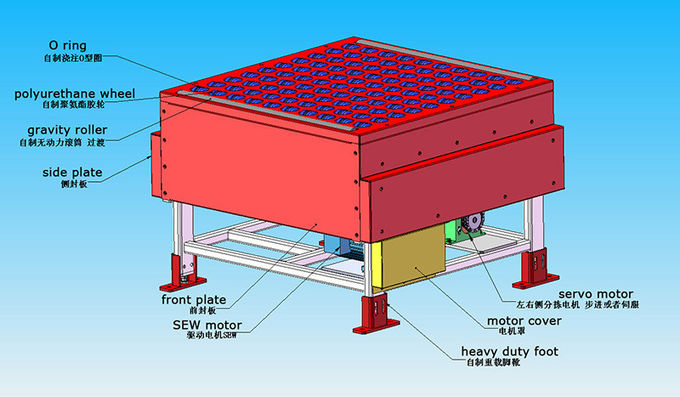

Equipment composition

The wheel diverting sorter is mainly composed of polyurethane wheels, driven motor, O belts, control cabinet and other components. It uses thrust ball bearing inside to switch the direction. Polyurethane wheels, O belts, U supporting form the pendulum mechanism. The wheels and O belts supply the straight driving force. The connecting rods and thrust ball bearings supply the switching force for left and right sorting so as to achieve two-way diverting, so the goods can be sorted.

General view

1) Wheel diverting sorter: supply driven force for the parcel moving.

2) Carbon steel plate: the mechanical structure of the equipment.

3) Wheels: made of polyurethane, then precisely processed. They are the key parts of the conveying and diverting.

4) O belts: made of polyurethane, the main part of transmission.

5) Motor: driven force

6) Gravity roller: increase the smooth moving.

Application

This equipment is used for the occasions of sorting, diverting and conveying together. Can be used with conveyors, scanning and weighing and WCS software.

Installation and commissioning

All parts are driven by connecting rods, easy to assemble, interchangeable and universal.

The installation and commissioning of the equipment are required to operate by our professional and technical personnel or the operaters authorized by our company. Equipment must be installed with matched mounting brackets. Forklift or crane will be used to move the equipments to place it in the designated location.Make sure the equipment aligns and all fasteners are installed firmly.

After the main structure of the equipment is installed, then start to install the electrical control components. All the equipment has an independent control cabinet, connected with the main equipment by communication bus standard and fast joints to ensure the fast and accurate installation.

After finishing installation, start to connect the software and test. It can be used with independent system or with other systems.

Maintenance

Mechanical part: Routine inspection of the drive shaft, make sure there is enough oil in the bearing. It is necessary to clean up the surface dust and dirt regularly to ensure the smooth operation of the mechanism.

Electric part: Daily inspection of electrical components in the control cabinet to prevent the leakage of mouse biting or water soaking.