Shanghai Genius Industrial Co., Ltd |

|

Verified Suppliers

|

|

Arc welding robot control program introduction

The most widely used and most used industrial robots are welding robots. The whole welding robot is composed of robot body, welding power source, fixture, peripheral equipment, safety fence, safety protection and clearing gun system. Users can also combine designs according to different characteristics of products and production needs. The use of welding robots is inseparable from the control program, which includes the generation of programs and the running of programs.

In the program generation process, the control program of the welding robot is generated by teaching. First, a new program framework is generated. The robot teaches through the teaching box, and at the same time, under the control of the teaching box axis operation keys, according to the specified coordinates or the joint moves, and the robot moves to the desired target point under the operation of the operator. When it is determined that the teaching point is valid, the controller generates a motion command and simultaneously records the current axis position data as the associated position of the corresponding motion command in the program data.

At this point, you only need to record the position of each axis,

you can calculate the corresponding coordinate value of the robot

in other position coordinates. Programs generated through teaching

are generally subject to trial run to facilitate inspection and

debugging of the program.

In the running process of the program, the robot has demonstrated

the production of single - variety, continuous production, multi -

variety rotation production, random production of different

varieties, etc. Therefore, there are various procedures to start,

but the ultimate goal is to good work is done smoothly.

Genius Industrial arc welding robot have independent developed core components, first - rate price, independent developed anti - collision design, first - class safety, open control system, first - class compatibility, high rigidity body design, first - rate accuracy.

Arc welding robot body specification

| Robot model | GNS1400W - 06 | |

| Application | Arc welding | |

| Mounting | Vertical ground installation | |

| Number of axes | 6 | |

| Payload | 6kg | |

| Max working radius | 1400mm | |

| Repeated posiontioning accuracy | 0.03mm | |

| Maximum joint range | J1 | RV reducer ±160° |

| J2 | RV reducer +110°, -70° | |

| J3 | RV reducer +65°, -120° | |

| J4 | RV reducer ±150° | |

| J5 | Hollow harmonic reducer +105°, -110° | |

| J6 | Hollow harmonic reducer ±320° | |

| Maximum joint speed | J1 | RV reducer 201.9°/S |

| J2 | RV reducer 198.3°/S | |

| J3 | RV reducer 198.3°/S | |

| J4 | RV reducer 296.2°/S | |

| J5 | Hollow harmonic reducer 197.5°/S | |

| J6 | Hollow harmonic reducer 247.2°/S | |

| Allowable bending moment N.m | J4 | RV reducer 9.8N.m |

| J5 | RV reducer 9.8N.m | |

| J6 | Hollow harmonic reducer 4N.m | |

| Allowable inertia Kg.㎡ | J4 | RV reducer 0.3kg.㎡ |

| J5 | RV reducer 0.3kg.㎡ | |

| J6 | Hollow harmonic reducer 0.05kg.㎡ | |

| Body total weight | KG | 185KG |

| Operating environment | Temperature | 0℃ - 45℃ |

| Humidity | 20% - 80% | |

| Others | Keep away from corrosive gases or liquids or explosive gases, | |

| Power capacity | 6KVA (Robot) + 24KVA (Welding source | |

Control system introduction

Integrated drive and control, open control system, comprehensive

compatibility.

1. Adapt to a variety of welding power

2. Restarting a weld / arc reignition

3. Arc breaking restart

4. Scratch start

5. Sticky wire detection

6. (2D 3D 4D seek) Starting point search

7. Multistation reservation.

8. Swing arc ( Positive arc, Triangular arc, circular arc ) .

Welding power source introduction

ATIG - PACIII - R series is fully digital models with high end DSP technology, suitable for both automatic application and manual welding. it offers advanced wave control technology which brings more flexibility for thinner / thicker material during critical alumumium welding. Smart parameters adjuestment brings cleanest, deepest penetration and perfect welding result for high welding quality demanding.

FAQ

Q: Are you a manufacturer or a trading company?

A: We are a manufacturer, and our factory located in Nantong city,

Jiangsu province. Our company occupies an area of 32,000 square

meters, with a plant area of 25,000 square meters. It has 72 senior

technicians, 42 technicians directly researching and developing, we

are a manufacturer with strong R&D capabilities and own core

technology, sincerely welcome to visit our factory.

Q: How about your after - sale service?

A:

1. Installation Services: In the period of installation and

debugging, we shall offer training about effective operation and

maintenance.

2. Technical Services: We can assist our clients to solve all kind of technical problems with our capable technical team, and we own adequate experience for production line transformation project.

3. Warranty Services: We offer free after sale service except the

engineers' traveling expense for any quality problem occurs during

our 12 months warranty period.

.

Q: What is your payment term?

A: The payment method is 50% prepayment, 50% balance before cargo

delivery if the client does not need onsite installation or

debugging;

The payment method is 50% prepayment, 40% balance before cargo

delivery, 10% upon verification in the client’s factory if the

client needs onsite installation or debugging.

Q: Can you provide customized service for our product?

A: Yes. We will provide you the professional robotic welding system

solutions according to your specific product. Only you need to send

us your detailed product drawings and welding requirement, then we

will come out with the customized technical proposal for you.

Q: What does the whole welding robot system include?

A: The whole welding robot system includes the robot arm, controller,

welding power source, positioners (one - axis or two axis),

fixtures, welding gun cleaner, safety fence, etc.

Q: What's the warranty period and delivery time?

A: Warranty period is 12 months. While the delivery time would be

within 15 - 30 days after receiving your deposit.

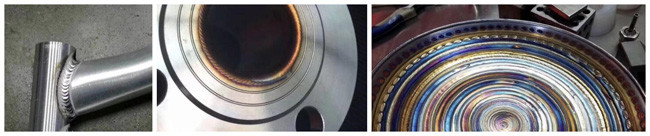

Welding effect

1. The surface has no rust, no high height, the welding is full and

the interface is firm.

2. The welding is consistent and does not need to be polished or

reduced by two-thirds.

3. There are no pores, cracks, unfused, slag inclusions, welds,

flying rafts, crater cracks, etc. on the surface.

Welding torch clearing device