Shanghai Genius Industrial Co., Ltd |

|

Verified Suppliers

|

|

Robotic arc welding machine description

The welding robot can perform welding work, control various welding

guns through the sensing system, and the sensing system has camera

and other control equipment. It is effective to perform butt

welding. Therefore, welding is generally divided into two systems,

one is the control system and the other is the operating system.

The welding robot is simple to weld and is suitable for welding

many kinds of materials, including stainless steel, carbon steel,

etc., and the welding quality is stable. Therefore, welding robots

can be widely used in various industrial fields.

Why choose Zhenkang robotic arc welding machine?

Robotic arc welding machine control system functions

Integrated drive and control, open control system, comprehensive compatibility.

Robotic arc welding machine robot body specification

| Robot model | ZK1400-06 | |

| Application | Arc welding | |

| Mounting | Vertical ground installation | |

| Number of axes | 6 | |

| Payload | 6kg | |

| Max working radius | 1400mm | |

| Repeated posiontioning accuracy | 0.03mm | |

| Maximum joint range | J1 | RV reducer ±160° |

| J2 | RV reducer +110°, -70° | |

| J3 | RV reducer +65°, -120° | |

| J4 | RV reducer ±150° | |

| J5 | Hollow harmonic reducer +105°, -110° | |

| J6 | Hollow harmonic reducer ±320° | |

| Maximum joint speed | J1 | RV reducer 201.9°/S |

| J2 | RV reducer 198.3°/S | |

| J3 | RV reducer 198.3°/S | |

| J4 | RV reducer 296.2°/S | |

| J5 | Hollow harmonic reducer 197.5°/S | |

| J6 | Hollow harmonic reducer 247.2°/S | |

| Allowable bending moment N.m | J4 | RV reducer 9.8N.m |

| J5 | RV reducer 9.8N.m | |

| J6 | Hollow harmonic reducer 4N.m | |

| Allowable inertia Kg.㎡ | J4 | RV reducer 0.3kg.㎡ |

| J5 | RV reducer 0.3kg.㎡ | |

| J6 | Hollow harmonic reducer 0.05kg.㎡ | |

| Body total weight | KG | 185KG |

| Operating environment | Temperature | 0℃ - 45℃ |

| Humidity | 20% - 80% | |

| Others | Keep away from corrosive gases or liquids or explosive gases, | |

| Power capacity | 6KVA (Robot) + 24KVA (Welding source) | |

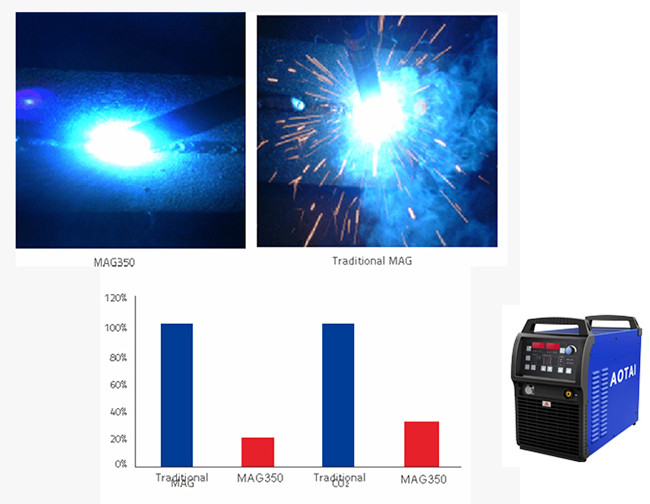

Robotic arc welding machine welding power source introduction

Robotic arc welding machine package

Company introduction

Shanghai Genius Industrial Co.,Ltd is the overseas sales service center of Nantong Zhenkang Welding Electromechanical Company, which was established in 1993, have 20years of history in the welding industry.

Our company professionally manufacture wire feeder, RV gear reducer and industrial robot, which is engaging in research and development, manufacture and sell.

FAQ

Q: Are you a manufacturer or a trading company?

A: We are a manufacturer, and our factory located in Nantong city,

Jiangsu province. Our company occupies an area of 32,000 square

meters, with a plant area of 25,000 square meters. It has 72 senior

technicians, 42 technicians directly researching and developing, we

are a manufacturer with strong R&D capabilities and own core

technology, sincerely welcome to visit our factory.

Q: Can you provide customized service for our product?

A: Yes. We will provide you the professional robotic welding system

solutions according to your specific product. Only you need to send

us your detailed product drawings and welding requirement, then we

will come out with the customized technical proposal for you.

Q: What does the whole welding robot system include?

A: The whole welding robot system includes the robot arm,

controller, welding power source, positioners (one-axis or two

axis), fixtures, welding gun cleaner, safety fence, etc.

Q: What's the warranty period and delivery time?

A: Warranty period is 12 months. While the delivery time would be

within 20 days after receiving your deposit.