Shanghai Genius Industrial Co., Ltd |

|

Verified Suppliers

|

|

High Precision Inline Cycloidal Gear Reducer Motor RV-160 Nabtesco

The cycloidal gear reducer is the part of the mechanical arm that is applied to the high - load one, two, and three joint shafts. It has large reduction ratio, light weight, large torque, precise positioning, high rigidity, and impact resistance. More than five times the torque, including the tool magazine, the fourth axis of the machine tool, the rotating shaft, medical equipment, aerospace equipment and other applications.

In the field of global industrial robot core components, the Japanese reducer brand Nabtesco has long occupied 60% to 80% of the international market share of precision reducers for industrial robots.

Zhenkang cycloidal gear reducer has won many large orders of AGV unmanned trucks in the world. Although the specifications of AGV unmanned vans are numerous, Zhenkang is one of the few manufacturers in the world that can undertake customized speed reducers.

Zhenkang has the most comprehensive cycloidal gear reducer comprehensive performance test platform, which can quickly and effectively measure RV gearbox backlash accuracy, transmission accuracy, efficiency, noise, stiffness, vibration and other performance indicators. The RV gearbox produced must pass the detection of the backlash accuracy, noise and stiffness, and the products that meet the enterprise standards can be shipped.

Cycloidal gear reducer RV-160E technical parameters

Operating parameter

| Output Rotational speed r/min | 5 | 15 | 25 | 35 | ||||

| Output torque | Input capacity | Output torque | Input capacity | Output torque | Input capacity | Output torque | Input capacity | |

| Model | Nm | kW | Nm | kW | Nm | kW | Nm | kW |

| 160E | 2215 | 1.49 | 1600 | 3.41 | 1358 | 4.77 | 1215 | 5.89 |

Note: the rated torque is the output torque when the output speed

is at 15r/min.

Performance Parameter

| Model | Speed ratio | Allowable output speed | Maximum backlash | Allowable acceleration/decleration torque | Momentary max allowable torque | Allowable moment | Momentary max allowable movement | Weight | Efficiency | Noise | |

| 160E | Shaft(R) | Housin | r/min | arc.min | Nm | Nm | Nm | Nm | kg | % | dB |

| 81 | 80 | 45 | 1 | 4000 | 8000 | 3840 | 7680 | 26.4 | >80 | <75 | |

| 101 | 100 | ||||||||||

| 129 | 128 | ||||||||||

| 145 | 144 | ||||||||||

| 171 | 170 | ||||||||||

Cycloidal gear reducer backlash and empty trip

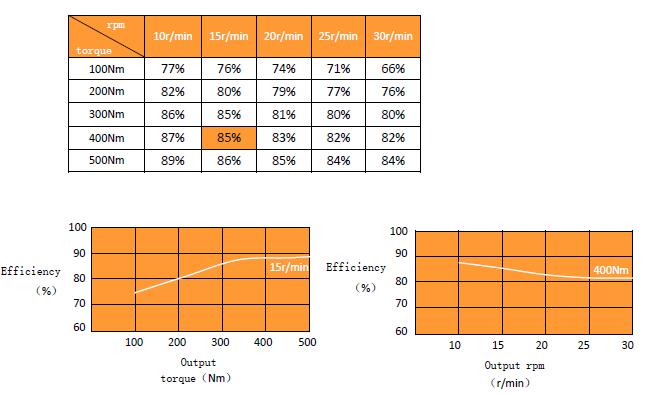

Cycloidal gear reducer efficiency

All E - Series gearboxes are rated for > 80 % efficiency.

40E efficiency example

Cycloidal gear reducer noise

The gear unit is operated at rated speed with a noise of <

75 dB.

The noise level is related to installation accuracy, lubrication,

temperature, load and other factors.

Cycloidal gear reducer torque

Cycloidal gear reducer working torque maximum: refers to the maximum torque of the reducer during start, steady

operation and stop.

Typically, the starting and stopping torque is approximately 2.5

times the rated torque;

The torque during steady operation is lower than the rated torque.

Cycloidal gear reducer maximum impact torque: refers to the maximum torque that the reducer can withstand when

subjected to external shock or emergency stop.

Note that the impact torque should be avoided as much as possible,

otherwise the performance of the reducer will decrease.

Cycloidal gear reducer bending moment

Cycloidal gear reducer maximum working moment: refers to the maximum bending moment of the reducer during start

- up, stable operation and stop.

The working bending moment is borne by the deep groove ball bearing

inside the reducer, and the speed reducer should not exceed its

maximum value when it is running.

Cycloidal gear reducer maximum impact moment: refers to the maximum bending moment that the reducer can

withstand when subjected to external impact or emergency stop.

Note that the impact bending moment should be avoided as much as

possible, otherwise the performance of the reducer will decrease.

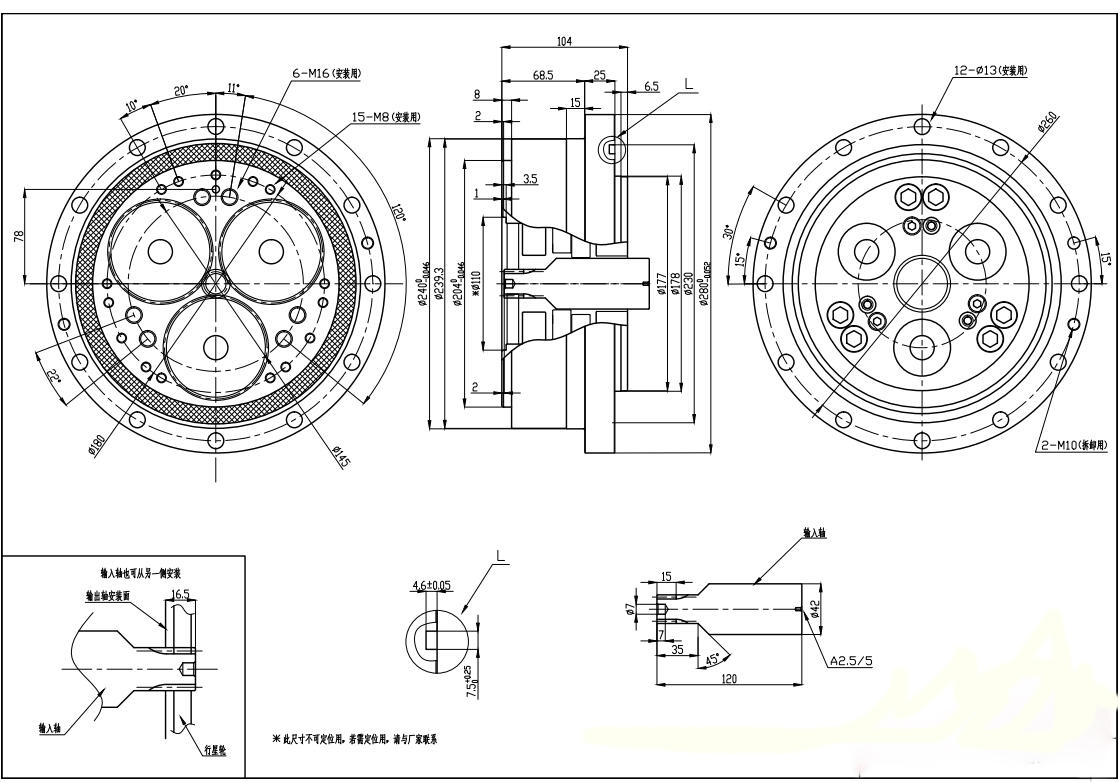

Cycloidal gear reducer ZKRV - 160E Installation parameter

| inner hexagon bolt Nominal dimension(mm) | fastening torque(Nm) | fastening force | bolt requirement |

| M8 × 1.25 | 37.2 ± 1.86 | 23960 | GB/T 70.1 - 2000 intensity:12.9 thread requirement:GB/T 1167-1996 |

| M16 × 2.0 | 318.5 ± 15.9 | 103410 |

Cycloidal gear reducer ZKRV - 160E installation drawings