Quanzhou Weforging Machinery Manufacturing Co., Ltd. |

|

Verified Suppliers

|

|

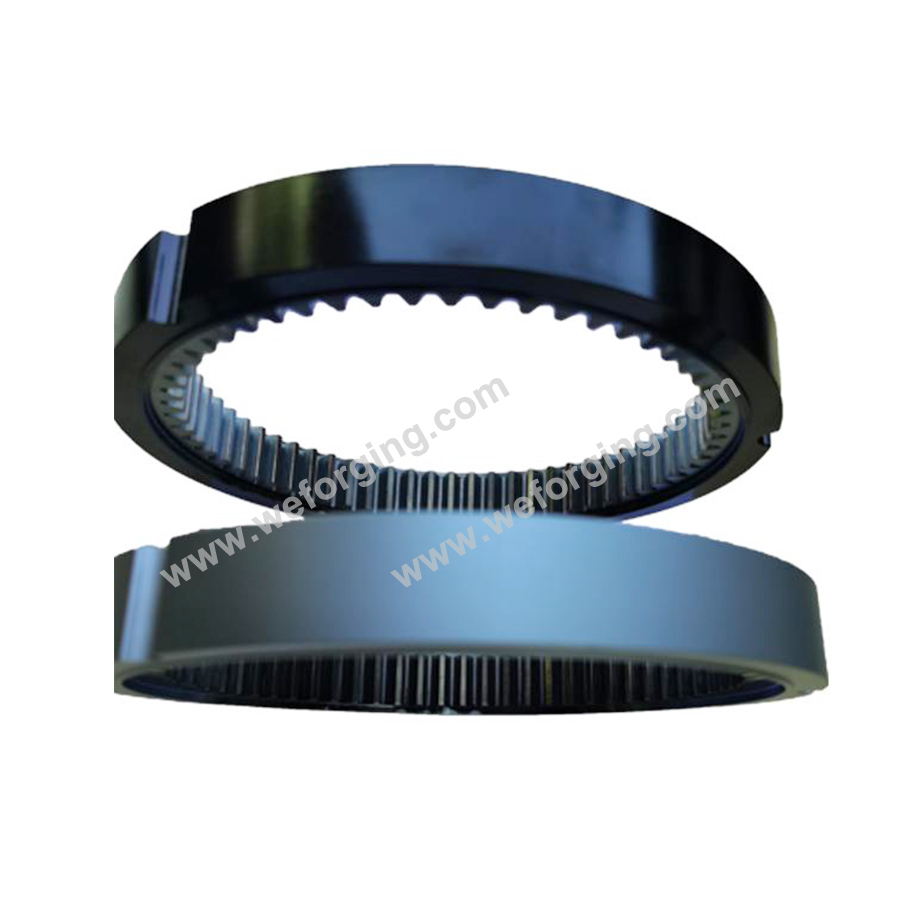

Precision GearBox Gear Manufacturing Company Diameter Planetary Gears For Gear Box Components 18CrNiMo7-6 For Machinery

Ring Gear is a type of spline gear shaft with an annular cut teeth. It is made from a variety of materials such as alloy steel, stainless steel, aluminum alloy, copper, titanium, and steel, and with a pressure angle of 20° and surface hardness of HRC50-62. It comes with an inner diameter of 800mm and outer diameter of 2000mm.

Ring Gears are mainly used in heavy machinery and equipment that require high accuracy and strength. It can be used in different industries such as automotive, aerospace, and marine. This type of gear is designed to be highly durable, reliable, and efficient. It is also easy to install and maintain.

Ring Gears provide superior performance and can be customized to fit specific applications. It is also cost-effective, making it a great option for many manufacturers. With its high-quality construction and precision engineering, Ring Gears are sure to provide long-term performance and reliability.

| Property | Value |

|---|---|

| Application | Industrial Machinery |

| Pressure Angle | 20° |

| Surface Hardness | HRC50-62 |

| Processing Method | Cutting, Hobbing |

| Heat Treatment | Carburizing And Quenching |

| Inner Diameter | 800mm |

| Tolerance | ±0.05mm |

| Tooth Number | 0-350 |

| Backlash | 0.01mm |

| Material | Alloy Steel, Stainless Steel, Aluminum Alloy, Copper, Titanium,Steel |

Ring Gear is an essential part of the gearworks that is used for transmitting power and motion. It has been developed to deliver high precision gears with excellent performance. ODM located in Quanzhou China, manufactures and supplies Ring Gear with ISO certification, which meets customer requirements. Our ring gears are made of Alloy Steel, Stainless Steel, Aluminum Alloy, Copper, Titanium and Steel, with outer diameter up to 2000mm and tooth number ranging from 0 to 350. Moreover, the surface hardness of our ring gears can reach up to HRC50-62, and the backlash is as low as 0.01mm.

If you are looking for an annular gear or spline gear shaft with high accuracy and reliability, ODM Ring Gear is the ideal choice. We accept orders with minimum quantity of 200 and offer competitive prices. Delivery could be arranged within 25-60 days and payment terms are TT. With the capacity of 10000 sets per month, we are sure to meet your needs in time.

Ring Gear is manufactured by ODM, a professional gear manufacturer based in Quanzhou China. Our Ring Gear products are certified by ISO and only available for purchase by order quantities of 200 or more. We offer flexible pricing options for our customers and accept TT payment terms. We are capable of delivering 10,000 sets per month. Our Ring Gears are available in various Tooth Numbers (0-350), Pressure Angles (20°), Outer Diameters (2000mm) and Inner Diameters (800mm). We also offer our Ring Gears in various materials, such as Alloy Steel, Stainless Steel, Aluminum Alloy, Copper, Titanium and Steel. If you are looking for a reliable Aluminum Gear, Wind Turbine Gear or Ring Gear manufacturer, look no further than ODM!

At Ring Gear, we understand the importance of providing reliable technical support and service. We offer a comprehensive range of services to help you ensure that your Ring Gear product is running smoothly and efficiently.

Our team of experienced technicians are available to come to your location and provide on-site support. Our technicians are knowledgeable and have the experience to diagnose and repair any Ring Gear product.

If you prefer to have remote support, our team of experts are available to help you via telephone, email, or live chat. We can provide troubleshooting and repair services remotely.

All Ring Gear products come with a standard warranty. Depending on the product, the warranty period can range from 1 year to 5 years. If you experience any issues with your Ring Gear product during the warranty period, we will repair or replace it at no cost.

Ring Gear will be packaged in cardboard boxes and shipped with UPS, FedEx, or USPS.

The box will include bubble wrap and other cushioning materials to ensure the product arrives in pristine condition.

Items will be shipped as soon as payment is received. Customers will be provided a tracking number to monitor their package.