Suzhou Jinyicheng Thread&Ribbon Co.,Ltd |

|

Verified Suppliers

|

|

Customer Logo 100% Polyester Nylon Jacquard Webbing Strap Belt For Luggage Seat Belt

Product Features | ||

Product Name | Polyester Webbing | |

Material | Polyester | |

Tenchnic | Woven | |

Width | 1cm | |

Feature | Soft,High Tenacity | |

Color | Any Colors Can Be Made | |

MOQ | 3000 meters,we also make small trial orders | |

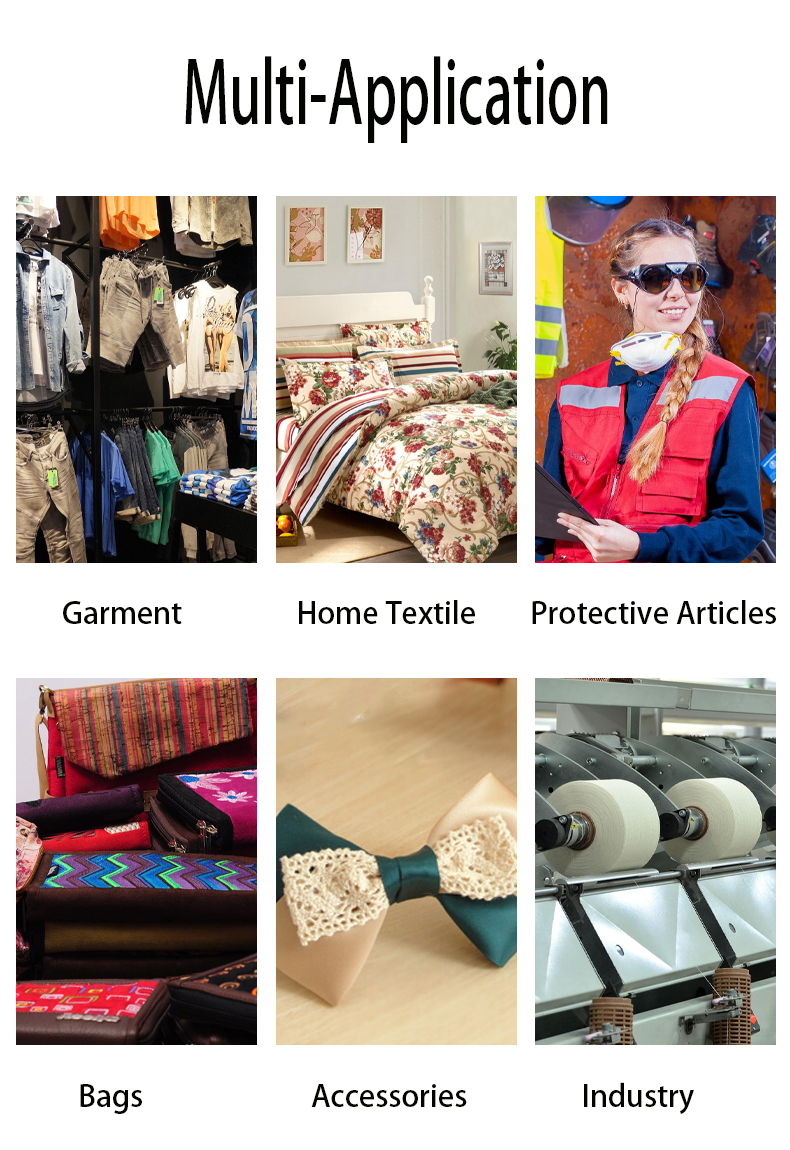

Usage | Garment, home textile, bag, etc. | |

Package | 1. Usually 50m/roll 2. Festoon packing 3.As your requirements | |

Payment | 30% T/T in advance, the balance paid against the B/L Copy or 100%

L/C at sight. | |

Delivery Time | 10 -15 days (depending on the order qty) | |

Shipment | By express (DHL, EMS, TNT,UPS, FEDEX)/by sea/air, etc. | |

FOB PORT | Shanghai,China | |

Quality Certification | Oeko-Tex | |

After-sales Service | We value after-sales service, we promise repairing, replacing and

refunding if there’s any quality problem of our products | |

Polyester Jacquard webbing is a type of woven webbing made from polyester yarns using the Jacquard weaving technique. It combines the durability and versatility of polyester with the intricate patterns achievable through Jacquard weaving.

The production process of polyester Jacquard webbing generally involves the following steps:

Design: The desired pattern or design for the Jacquard webbing is created or selected. This can be done through manual design or computer-aided design (CAD) software.

Warping: Polyester warp yarns are prepared and wound onto a beam according to the design specifications. The number of warp threads and their arrangement depend on the desired width and pattern of the webbing.

Weaving: The prepared warp beam is mounted onto a Jacquard loom. Polyester weft yarns are interlaced with the lifted warp threads according to the programmed design. The Jacquard loom controls the lifting and lowering of the warp threads to create the intricate Jacquard pattern.

Finishing: After weaving, the polyester Jacquard webbing undergoes various finishing processes to enhance its appearance, functionality, and durability. This may include treatments such as heat setting, dyeing, coating, or printing. Heat setting helps stabilize the webbing and minimize shrinkage.

Cutting and Packaging: Once the webbing has been finished, it is cut into the desired widths and lengths. This can be done using cutting machines or other cutting tools. The webbing is then packaged for shipping or distribution, typically rolled or folded and protected in packaging materials.

Throughout the production process, quality control measures are implemented to ensure the webbing meets the required specifications. This includes inspections for defects, testing for strength and durability, and checks for color consistency and pattern accuracy.

Polyester Jacquard webbing finds applications in various industries, including apparel, bags, belts, straps, home furnishings, and more. Its combination of strength, durability, and intricate patterns makes it a popular choice for products that require both functionality and aesthetic appeal.

The production process of polyester Jacquard webbing involves several stages, including design, warping, weaving, finishing, cutting, and packaging. Here is a general overview of the process:

Design: The first step is to create or select the desired pattern or design for the polyester Jacquard webbing. This can be done through manual design or using computer-aided design (CAD) software. The design determines the intricate pattern that will be woven into the webbing.

Warping: Polyester warp yarns are prepared and wound onto a beam. The number of warp threads and their arrangement depend on the desired width and pattern of the webbing. The warp yarns are typically wound under tension to ensure even distribution and prevent tangling.

Weaving: The prepared warp beam is mounted onto a Jacquard loom. The Jacquard loom uses a system of punched cards or digital controls to lift and lower individual warp threads. Polyester weft yarns are interlaced with the lifted warp threads to create the intricate Jacquard pattern. The loom controls the weaving process, ensuring the correct interlacement of the yarns.

Finishing: After weaving, the polyester Jacquard webbing undergoes various finishing processes to enhance its appearance, functionality, and durability. This may include treatments such as heat setting, dyeing, coating, or printing. Heat setting is often applied to stabilize the webbing and reduce shrinkage. Dyeing or printing can add color or patterns to the webbing, while coating can provide additional protection or desired properties such as water resistance.

Cutting: Once the webbing has been finished, it is cut into the desired widths and lengths. This can be done using cutting machines or other cutting tools, depending on the specific requirements. The webbing is typically cut with precision to ensure uniformity of size and shape.

Packaging: The final step involves packaging the polyester Jacquard webbing for shipping or distribution. The webbing is typically rolled or folded and placed into packaging materials to protect it during transportation and storage.

Throughout the production process, quality control measures are implemented to ensure the webbing meets the required specifications. This includes inspections for defects, testing for strength and durability, and checks for color consistency and pattern accuracy.

It's important to note that the specific details of the production process may vary depending on the manufacturer, equipment used, and the desired characteristics of the polyester Jacquard webbing. Specialized machinery and skilled technicians are typically involved in producing high-quality polyester Jacquard webbing.