Changsha Vibo Wearable Material Co., Ltd. |

1.9kgs 80x56x50mm 65HRC Sugar Mill Shredder Hammer Tips

| Product Description |

Shredder hammer maintenance is one of the main targets in cost

reduction efforts in cane crushing factories. Recent developments

in shredder hammer technology remain far from improving the current

situation in the matter of wear in cane preparation machinery.

Trials with very hard but brittle materials such as ceramics and

tungsten carbide tips had left white iron (FeCrC) alloys as the

most cost-effective choice, especially when used as replaceable

mild steel blocks with brazed tips. In an effort to develop a more

cost-effective solution, a combination of the replaceable block and

Flux-Cored Arc Welding (FCAW) (possible to be repaired a few times)

was evaluated under factory trials and with a comprehensive

analysis that includes maintenance costs, energy and pol losses in

bagasse. Wear performance of welded tips made with hardfacing

alloys and bolted to shredder hammers is reported and compared to

commercially available tips and other conventional technologies. It

was found that welded tips are likely to be cost effective under

the evaluated conditions and a complete welding procedure was

developed for production and maintenance of the tips.

Material

This Bi-metallic wear resistant product, as a combination of high

Chromium cast iron (ASTM A532 15/3CrMo, 700BHN - 63HRc)

metallurgically bonded to a mild steel backing plate, obtains both

very high abrasion resistance and weldability.

Product Dimensions

| Part No | Type | Size(mm) | Dimensions(mm) | Unit Weight(kgs) | ||||

| A | B | C | D | E | ||||

| H175 | 1 | 75x75x45 | 75 | 75 | 25 | 20 | 45 | 2 |

| H180 | 1 | 80x56x45 | 80 | 56 | 25 | 20 | 45 | 1.6 |

| H181 | 1 | 80x80x45 | 80 | 80 | 25 | 20 | 45 | 2.4 |

| H190 | 1 | 90x50x45 | 90 | 50 | 25 | 20 | 45 | 1.6 |

| H191 | 1 | 90x90x45 | 90 | 90 | 25 | 20 | 45 | 2.9 |

| H100 | 1 | 100x100x45 | 100 | 100 | 25 | 20 | 45 | 3.6 |

| H280 | 2 | 80x56x55 | 80 | 56 | 35 | 20 | 55 | 1.9 |

| H290 | 2 | 90x90x55 | 90 | 90 | 35 | 20 | 55 | 3.1 |

| H291 | 2 | 90x50x55 | 90 | 50 | 35 | 20 | 55 | 1.8 |

| H380 | 3 | 80x56x50 | 80 | 56 | 30 | 20 | 50 | 1.9 |

| H390 | 3 | 90x90x50 | 90 | 90 | 30 | 20 | 50 | 3.3 |

Product Drawing

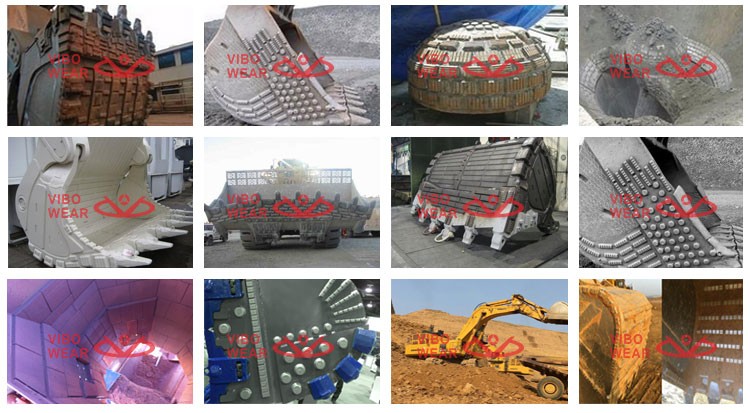

| Product Categories |

| 1. Chocky Bars and Blocks | 2. Wear Bars and Blocks | 3. Shaped Wear Bars |

| 4. Wear Buttons & Donuts | 4. Knife Edges | 6. Shredder Hammer Tips |

| 7. Skid Bars | 8. Wear Plates | 9. Grizzly Bars |

| 10. Chocky Rockbox Liners | 11. Dozer Blade | To View More |

| Company Profile |

VIBO Wear is a professional manufacturer of bimetallic composites and dozer blade, which focuses on wear solutions. VIBO factory covers 30000 square meters, and owns complete state-of-the art production line with capacity of 2000tons bimetallic wear parts and 6000tons dozer blade. Attributed to strong R & D ability, high quality and good service, VIBO sproducts have been widely distributed throughout America, Chile, Brazil, Australia, Canada, Russia, South Africa, as well as many other countries and areas. If you are looking for high quality wear-resistant parts,please feel free to contact us with any query, we are ready at your service at any time.

| Team & Exhibition |

| Product Application |

| Quality Control |

In order to ensure wear parts quality,VIBO executes strict quality control procedure in each step of producing. Before shipment,VIBO all products must pass checking at least including chemical, hardness, strength, ultrasonic, microstructure, visual and inspection report will be submitted to customer at the same time.

VIBO commit to replace defective goods 100%.

| Payment & Shipping |

PAYMENT Standard payment terms: 30% T/T deposit,balance against the copy of B/L More payment terms could be provided (LC/DA/DP PAYPAL WESTERN UNION)

|  |

| |

SHIPPING Delivery time: 15 days after deposit payment received(based on order quantity) Packing: Plywood box or customized packing as your request.

| |

| FAQ |

| Q: Are you a trade company or a manufacturer ? |

| A: We are ISO9001:2008 Certificated factory. |

| Q: Can you provide samples ? is it free or extra ? |

| A: Yes, we can provide free samples for customer’s testing. |

| Q: Can I have my logo in your product ? |

| A: Yes, OEM and ODM are available for us. |

| Q: Can I have a visit to your factory before the order ? |

| A: Sure,welcome to visit our factory . We can pick you up in the airport. Hotel booking service is available. |