Changsha Vibo Wearable Material Co., Ltd. |

|

Temperature Resistance 63HRC 64HRC Ni Hard / Low Alloy Bi Metal Casting

| Product Description |

Based on the casting compound ,white iron casting and low alloy casting combine together to achieve the purpose of improving wear resistance, ease to assemble. lower cost than vacuum brazing.

Casting including grate bar/white iron casting( Cr1 5Mo3/Cr27)/Ni- hard/low alloy

Advantages:

| material | white iron casting+low alloy casting steel |

| color | customized |

| size | customized |

| packing | wood cases |

| certificates | ISO90001 |

| brand | vibo |

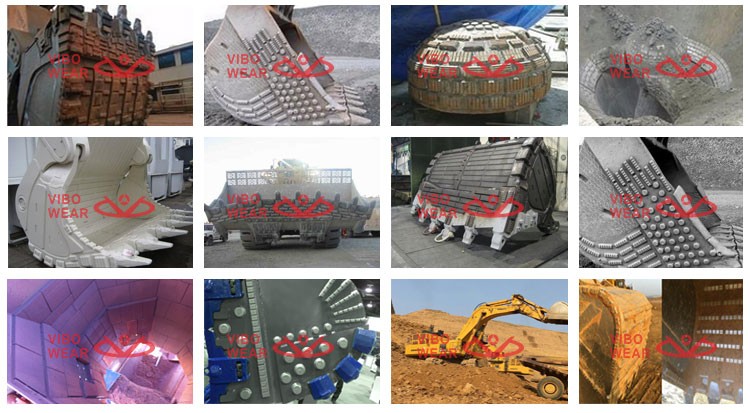

| Product Categories |

VIBO is a professional manufacturer of vacuum-brazing bimetallic composite,white iron casting with ceramic-inserted,wear parts with Tungsten carbide,casting bonding bi-metal,Ni-hard casting Tungsten carbide/ceramic inserted casting,tungsten carbide Vacuum-brazing wear parts with annual turnover of more than thirty million US dollar. VIBO factory covers 53000 square meters land,Owns a state-of-the-art production line with annual capacity of more than 10000 tons wear parts.VIBO customers are from global mining,oil sands,steel,cement,power,crushing,aggregate,recycling,dredging and sugar industry.VIBO products are widely distributed to North/South America,Europe,Australia,Southeast Asia.Our wear parts provide high wear-resistant quality ,as well as resistant-impact/erosion/corrosion/friction/abrasion and high temperature function.We are ready at your service.

| Team & Exhibition |

| Product Application |

| Quality Control |

In order to ensure wear parts quality,VIBO executes strict quality control procedure in each step of producing. Before shipment,VIBO all products must pass checking at least including chemical, hardness, strength, ultrasonic, microstructure, visual and inspection report will be submitted to customer at the same time.

VIBO commit to replace defective goods 100%.

| Payment & Shipping |

PAYMENT Standard payment terms: 30% T/T deposit,balance against the copy of B/L More payment terms could be provided (LC/DA/DP PAYPAL WESTERN UNION)

|  |

| |

SHIPPING Delivery time: 15 days after deposit payment received(based on order quantity) Packing: Plywood box or customized packing as your request.

| |

| FAQ |

| Q: Are you a trade company or a manufacturer ? |

| A: We are ISO9001:2008 Certificated factory. |

| Q: Can you provide samples ? is it free or extra ? |

| A: Yes, we can provide free samples for customer’s testing. |

| Q: Can I have my logo in your product ? |

| A: Yes, OEM and ODM are available for us. |

| Q: Can I have a visit to your factory before the order ? |

| A: Sure,welcome to visit our factory . We can pick you up in the airport. Hotel booking service is available. |