Changzhou Victory Technology Co., Ltd |

|

Verified Suppliers

|

|

Introduction:

GH4080A high-temperature alloy, also known as GH80A, is a nickel-based high-temperature resistant alloy widely used in critical high-temperature components in aerospace and other fields. This alloy can work for a long time in a temperature range of 650°C to 850°C, maintaining the strength and stability of the material. It is a product of the development of modern industrial technology.

This alloy is suitable for high temperature environments below 800 degrees Celsius. One of its characteristics is that elements such as aluminum and titanium are added to the alloy to form a precipitation strengthening phase. GH4080A exhibits excellent creep resistance in the range of 650℃ to 850℃. In addition, the alloy has excellent hot and cold processing properties.

GH4080A alloy has excellent high temperature strength and good corrosion resistance. Under continuous or intermittent high-temperature conditions, the alloy can maintain excellent mechanical properties, such as tensile strength and yield strength, which is crucial for aerospace engine components that withstand high-temperature operating environments.

Parameter:

Carbon (C): 0.04-0.10%

Silicon (Si): Not more than 0.8%

Manganese (Mn): Not more than 0.4%

Phosphorus (P): Not more than 0.02%

Sulfur (S): Not more than 0.015%

Chromium (Cr): Between 18% and 21%

Nickel (Ni): Balance

Density: The density of GH4080A alloy is 8.15 g/cm. The moderate density helps reduce the weight of parts.

Magnetism: This alloy is non-magnetic and is suitable for some applications that require strict magnetic properties.

Thermal conductivity: In the range of 100-900℃, the thermal conductivity of GH4080A is 12.11-27.66 W/(m·k), which has good thermal conductivity.

Resistivity: The resistivity of the alloy at 20°C is 1.34ω·mm/m.

Linear expansion coefficient: In the range of 25~800℃, the linear expansion coefficient is 16.2×10-6/k, which has good thermal expansion performance.

Mechanical properties: GH4080A alloy has high tensile strength and good elongation, and is suitable for high stress environments.

Processability and welding process: The alloy has good processability, can be automatically butted by argon arc welding and seam welding, and is suitable for various processing processes.

| Chemical Composition ( % ) | |||||||||||||||||||||||||||||||||||

| Brand | C | Si | Mn | S | P | Cr | Co | W | Mo | Ti | Al | Fe | Ni | other | |||||||||||||||||||||

| Less than | |||||||||||||||||||||||||||||||||||

| GH4080A | 0.04~0.1 | 0.8 | 0.4 | 0.015 | 0.02 | 18~21 | ≤2 | — | — | 1.8~2.7 | 1~1.8 | ≤1.5 | rest | Cu≤0.2 B≤0.008 | |||||||||||||||||||||

| The minimum mechanical properties of the alloy at room temperature | ||||||

| Brand | heat treatment | tensile strength RmN/mm² | Yield strength Rp0.2N/mm2 | Elongation As% | Brinell hardness HB | Rockwell hardness HRC |

| GH4080A | solid solution + aging | 930 | 620 | 20 | — | |

Characteristic:

Specific application areas:

GH4080A is widely used in aerospace engines, petrochemical equipment and energy fields. In the aviation field, it is used to manufacture high-temperature components, such as turbine blades, combustion chambers, etc. In the petrochemical industry, it can be used to manufacture high-temperature and high-pressure reactors and heat exchangers. In the energy sector, it is used to make gas turbines and other equipment.

|  |

contact us

email:victory@dlx-alloy.com

Oem service:

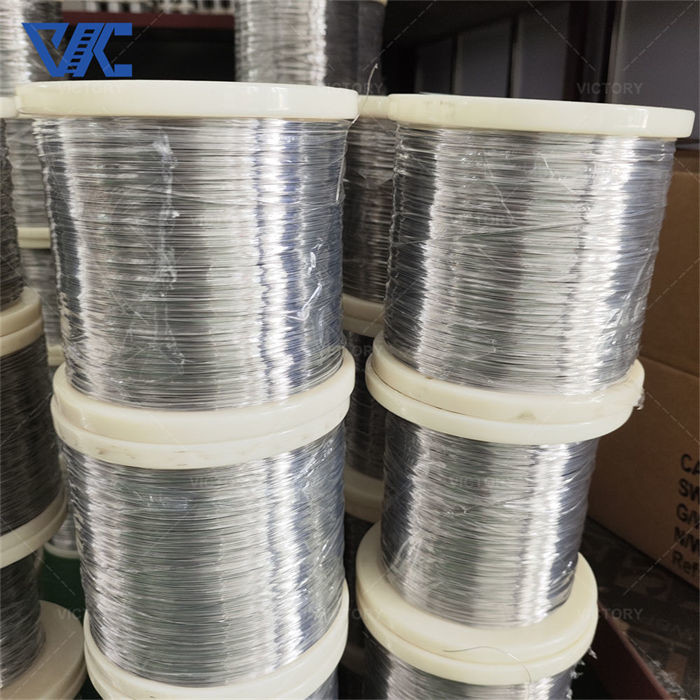

Welcome customized size

We are experience factory for OEM&ODM service