Changzhou Victory Technology Co., Ltd |

|

Verified Suppliers

|

|

Inconel series include codes?

Inconel 600

Chemical composition: Ni 72%, Cr 14-17%, Fe 6-10%

Widely used in high-temperature corrosive environments such as

chemical industry and power generation

Inconel 601

Chemical composition: Ni 60-63%, Cr 23-25%, Al 1.0-1.7%

Has excellent high temperature strength and corrosion resistance

Inconel 617

Chemical composition: Ni 44-46%, Cr 20-24%, Co 10-15%, Mo 8-10%

High temperature strength, still good strength above 1100°C

Inconel 625

Chemical composition: Ni 58%, Cr 20-23%, Mo 8-10%, Nb 3.15-4.15%

Excellent corrosion resistance and high temperature mechanical

properties

Inconel 718

Chemical composition: Ni 50-55%, Cr 17-21%, Fe bal., Nb+Ta

4.75-5.5%

High temperature resistance and strength, widely used in aerospace

engines, etc.

Inconel 725

Chemical composition: Ni 58%, Cr 20-23%, Mo 8-10%, Nb 3.15-4.15%

Similar to Inconel 625, but slightly less strong

Difference from Inconel 625 and Inconel 600?

Chemical composition:

Inconel 625 contains higher niobium (Nb) and molybdenum (Mo)

contents, 3.15-4.15% and 8-10% respectively. Inconel 600, on the

other hand, contains only very small amounts of Nb and Mo.

Inconel 625 contains a lower chromium (Cr) content of 20-23%, while

Inconel 600 has 14-17%.

Performance features:

Inconel 625 has better corrosion resistance, especially in

seawater, acidic and oxidizing environments.

Inconel 625 has higher strength and hardness and can maintain good

strength at high temperatures.

Inconel 625 has better resistance to stress corrosion cracking.

Application areas:

Inconel 625 is widely used in marine, chemical, military and other

applications requiring high corrosion resistance.

Inconel 600 is more used in conventional high-temperature

environments, such as power plants, petrochemical equipment, etc.

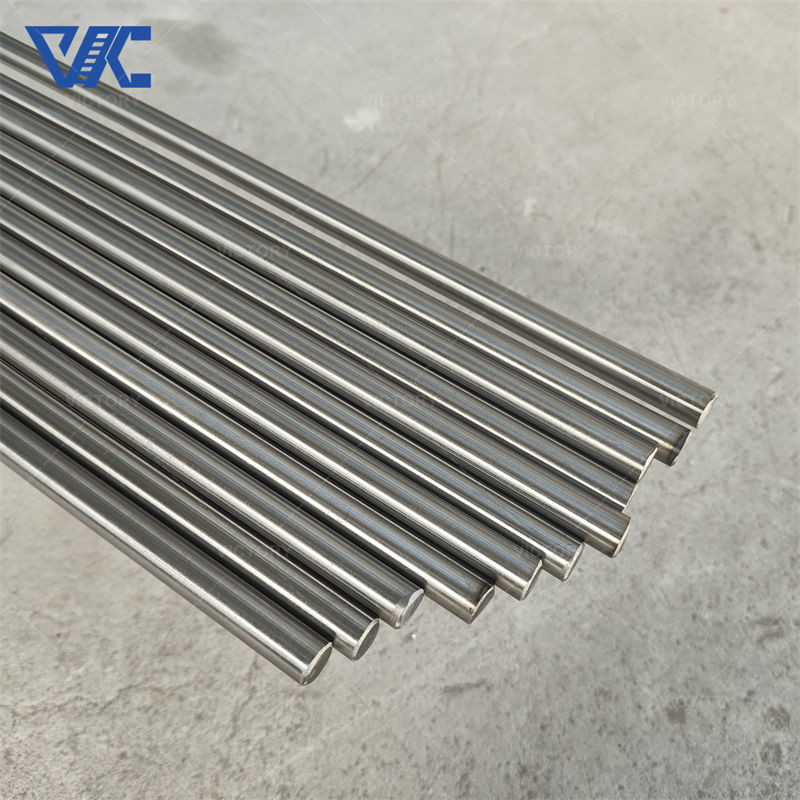

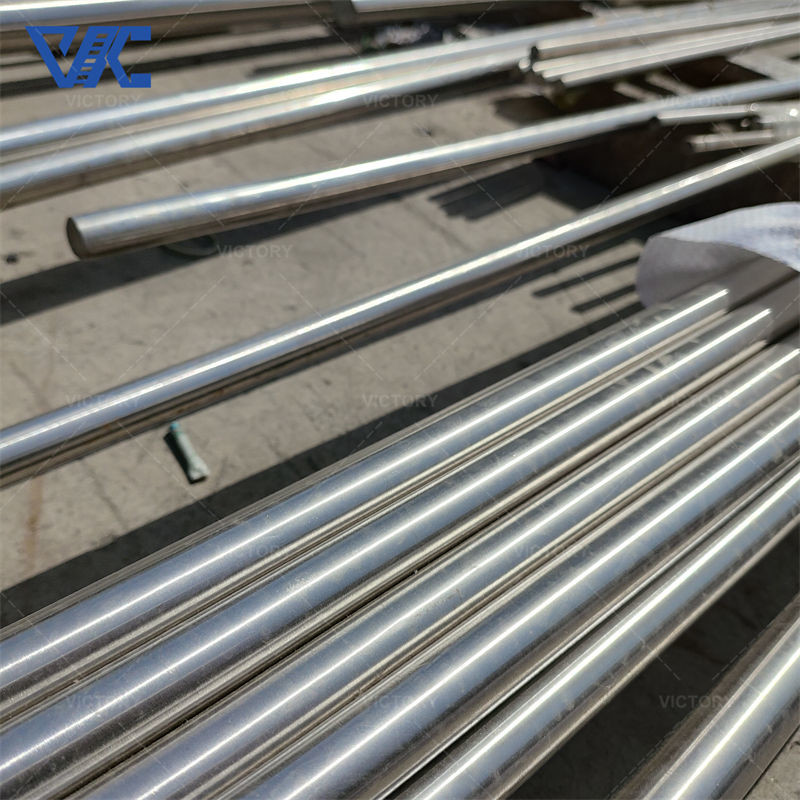

what's the production process of inconel 600 round bar?

Smelting:

An electric arc furnace or induction furnace is used to smelt

nickel, chromium, iron and other raw materials to produce Inconel

600 alloy melt.

Casting:

Inject the molten Inconel 600 alloy into a water-cooled metal mold

for continuous casting or sand casting to obtain a rough casting.

forging:

The rough casting is heated to the plastic temperature and then

forged or extruded to obtain a prefabricated billet.

Hot rolled:

The prefabricated billet is heated to a specified temperature and

then rolled repeatedly through a hot rolling mill until a round

steel bar of the required diameter is obtained.

annealing:

The rolled round steel bars are annealed to improve their

plasticity and corrosion resistance.

Inspection and surface treatment:

The rolled and annealed Inconel 600 round steel bars were tested

for size, chemical composition, mechanical properties, etc.

Surfaces are polished, pickled or otherwise treated as required to

meet the end product's usage requirements.

what's the main application of Inconel 600 round bar?

Chemical industry:

Used to manufacture various chemical reactors, storage tanks,

pipelines and other equipment, with excellent corrosion resistance.

It is widely used in corrosive environments in petrochemical,

pharmaceutical, pulp and other industries.

Power generation industry:

As parts and materials for steam turbines, generators and heat

exchange equipment, such as turbine blades, bearings, seals, etc.

It has good strength and corrosion resistance in high temperature

and high pressure environments.

Aerospace field:

Special components used in the manufacture of aircraft engine

parts, missiles and spacecraft.

Materials are required to have excellent corrosion resistance, high

temperature resistance and other properties.

Chemical Properties of Inconel 600

| C | Cr | Ni+Co | Al | Ti | Fe | Nb+Ta | Mn | Si | P | S | Cu |

| ≤0.15 | 14.0~17.0 | ≥72 | ≤0.35 | ≤0.50 | 6.0~10.0 | ≤1.0 | ≤1.0 | ≤0.5 | ≤0.04 | ≤0.015 | ≤0.5 |

| ITEM | θ/℃ | TENSIE STRENGTH | HBS | |||

| σb/MPa | σP0.2/MPa | δ5/% | φ/% | |||

| BAR/ROD | 20 | ≥585 | ≥240 | ≥30 | - | 134~217 |

| RING | 20 | ≥520 | ≥205 | ≥35 | - | ≥187 |

| HOT ROLL PLATE | 20 | ≥550 | ≥240 | ≥35 | ≥40 | - |

| 900 | ≥95 | ≥45 | ≥40 | ≥50 | - | |

| COLD ROLLED SHEET | 20 | ≥550 | ≥240 | ≥30 | - | - |

| 900 | ≥90 | ≥40 | ≥60 | - | - | |

| COLD ROLLED SHEET | 20 | ≥550 | ≥200 | ≥30 | - | - |

| STRIP | 20 | ≥550 | ≥240 | ≥30 | - | - |

| WIRE | 20 | - | HV≤151 | |||

Shape | Size(mm) |

WIre | 0.5-7.5 |

Rod/Bar | 8.0-200 |

Strip | (0.5-2.5)*(5-180) |

Tube | custom made |

Plate | custom made |

contact us

email:victory@dlx-alloy.com

Oem service:

Welcome customized size

We are experience factory for OEM&ODM service