Changzhou Victory Technology Co., Ltd |

|

Verified Suppliers

|

|

Introduction:

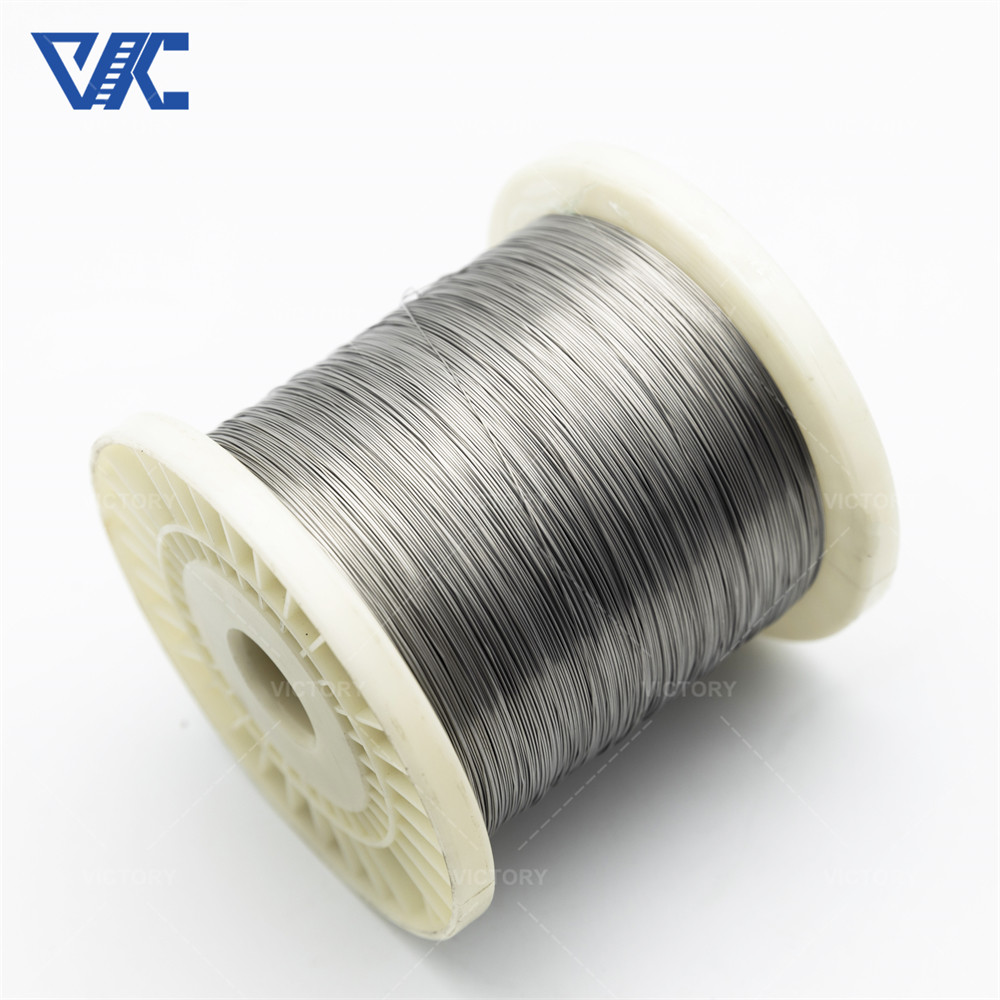

GH4169 wire, also known as Inconel 718, is a nickel-based high-temperature alloy wire. It is a material with excellent high temperature strength, corrosion resistance and heat resistance.

The main components of GH4169 wire include nickel (Ni), chromium (Cr), iron (Fe), titanium (Ti) and other elements. It has excellent high temperature stability and can maintain excellent mechanical properties and corrosion resistance in high temperature environments. The material also exhibits excellent heat resistance and has good oxidation resistance and creep resistance.

GH4169 wire is widely used in aerospace, energy, chemical and other fields. In the aerospace field, it is often used to manufacture aircraft engine components, combustion chambers, turbine blades and high-temperature structural parts. In the energy field, GH4169 wire can be used to manufacture oil and gas extraction equipment, nuclear power plant components, and turbine and generator components. In addition, it is also used in high-temperature reactors, catalysts and steam generators in the chemical industry.

GH4169 wire has good processability and can be processed and formed through heat treatment, cold working and welding. Its high-temperature strength, corrosion resistance and heat resistance make it an ideal material choice for high temperatures and extreme environments. Whether in the fields of aerospace, energy or chemical industry, GH4169 wire has demonstrated excellent performance and reliability.

Parameter:

Nickel (Ni): about 50-55%

Chromium (Cr): about 17-21%

Iron (Fe): about 17-21%

Density: about 8.2 g/cubic centimeter

Melting point: about 1260-1340 degrees Celsius

tensile strength:

Room temperature strength (yield strength): about 965 MPa (MPa)

Room temperature tensile strength: about 1030 MPa (MPa)

Thermal expansion coefficient: approximately 12.1 x 10^-6/degrees

Celsius (from room temperature to 100 degrees Celsius)

Corrosion resistance: GH4169 exhibits excellent corrosion resistance and has good resistance to many acidic and alkaline media.

Inconel718 (USA), NC19FeNb France

| Chemical Composition ( % ) | |||||||||||||||||||||||||||||||||||

| Brand | C | Si | Mn | S | P | Cr | Co | W | Mo | Ti | Al | Fe | Ni | other | |||||||||||||||||||||

| Less than | |||||||||||||||||||||||||||||||||||

| GH4169 | 0.08 | 0.35 | 0.35 | 0.015 | 0.015 | 17~21 | ≤1 | 2.8~3.3 | 0.65~1.15 | 0.2~0.8 | rest | 50~55 | Cu≤0.3 Nb:4.75-5.5 Mq≤0.01 B≤0.006 | ||||||||||||||||||||||

| The minimum mechanical properties of the alloy at room temperature | ||||||

| Brand | heat treatment | tensile strength RmN/mm² | Yield strength Rp0.2N/mm2 | Elongation As% | Brinell hardness HB | Rockwell hardness HRC |

| GH4169 | solid solution + aging | 1275 | 1034 | 15 | ≥331 | |

Characteristic:

Specifications and condition:

We can supply die forgings (discs, disk integral forgings), cakes, rings, bars (forged bars, rolled bars, cold drawn bars), plates, wires, belts, tubes, fasteners of different shapes and sizes, elastic components, etc. The delivery status is agreed between the supplier and the buyer. Wire is delivered in reels in the agreed delivery condition.

The alloy smelting process is divided into three categories: vacuum induction electroslag remelting; vacuum induction plus vacuum arc remelting; vacuum induction plus electroslag remelting plus vacuum arc remelting. According to the use requirements of the parts, the required smelting process can be selected to meet the application requirements.

Specific application areas:

|  |

contact us

email:victory@dlx-alloy.com

Oem service:

Welcome customized size

We are experience factory for OEM&ODM service