Xinxiang AAREAL Machine Co.,Ltd |

|

2000mm Food Grade Stainless Steel 316L Tumbler Screening Machine for Sea Salt Screening

Overview of 2000mm Food Grade Stainless Steel 316L Tumbler Screening Machine for Sea Salt Screening:

AAREAL can make tumbler screen for sea salt screening. Unlike the typical vibratory or gyratory screening machine, the tumbler screening machine incorporates a unique three-dimensional tumbling motion providing the gentlest screening possible. This motion prevents delicate, friable material from being broken resulting in less undesirable fine generation and dust levels. Even the most difficult materials, which tend to blind screens, are screened efficiently by utilizing the proper anti-blinding systems including motor driven brushes and/or air knives that are unique to tumbler type screening machines.

AAREAL tumbler screen machines are used for bulk material grading, safety screening, and dedusting in all industrial sectors. They are particularly well-suited to the fine and extremely fine screening of dry bulk materials and precise grading with up to 6 particle sizes. Our AM model tumbler screen machine features a range of customization options designed to meet extremely demanding requirements, as well as a broad variety of additional equipment options. Among these, the number of available screen cleaning systems is particularly worth mentioning, with balls, brushes, ultrasonic system, and various combinations being of these options are available to prevent blinding and maintain efficient screening.

Important Information About 2000mm Food Grade Stainless Steel 316L Tumbler Screening Machine for Sea Salt Screening You Won't Miss:

| Motion | involute spiral tumbling motion |

| Screening Accuracy | upto 90%~99.9% |

| Mesh Cleaning Method | bouncing balls cleaning, ultrasonic system cleaning, brush cleaning, air cleaning, ultrasonic air cleaning, air brush cleaning |

| Screen Structure | adhesive screen, or splicing segmented screen etc. |

| Layers of Screen | 1~5 layers of screen with 6 outlets (suggest 1~3 layers) |

| Diameter | 600mm, 1000mm, 1200mm, 1400mm, 1500mm, 1600mm, 1800mm, 2000mm, 2100mm, 2300mm etc. |

| Advantages | soft rock screening will not destroy the particles original structure of the material and not easy to produce static electricity |

| Optional | pneumatic lifting devices, quick clamps etc. |

| Application | can be used for material that is flammable, explosive and easy to generate static |

| Motor Brand | China made brand, Siemens, ABB etc. |

Characteristics of 2000mm Food Grade Stainless Steel 316L Tumbler Screening Machine for Sea Salt Screening:

Working Principle of 2000mm Food Grade Stainless Steel 316L Tumbler Screening Machine for Sea Salt Screening:

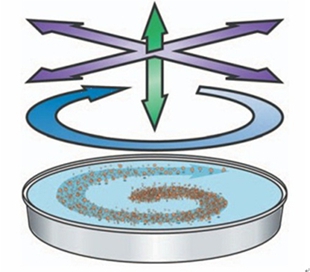

While the tumbler screening machine is running, its radial inclination ensures that the material being screened moves from the center of the screen outwards, while its tangential inclination makes the material move in circular fashion on the screen. The interaction between the two resulting forces makes the particles being screened move in a spiral pattern on the screen fabric, ensuring that the particles stay a long time on the screen. This, in turn, enables the machine to achieve an optimum level of grading accuracy with respect to the particle size ranges while simultaneously minimizing oversize and fines contamination.

The movement of a tumbler screening machine is usually compared with simple hand screening. The product is continuously fed into the center of the top screen, from where it spreads out evenly to the outside across the entire screening surface. The finer particles fall through the screen near the center and the coarser ones successively towards the periphery. The material is moved in a spiral pattern with increasing acceleration of the particles the further they are from the centre, with the result that even those particles which are almost the same size as the screen mesh are screened. All the separated fractions are discharged through the lateral outlets. The screening process is repeated again and again on each deck.

Application of 2000mm Food Grade Stainless Steel 316L Tumbler Screening Machine for Sea Salt Screening:

AAREAL tumbler screening machine can be used by multiple industry companies that work with material particles required to be filtered, such as:

Activated Carbon

Food and spices

Sugar

Salt

Chemical

Rubber

Fertilizer

Plastics

Medicine

Wood and Plywood

Fodder

Mining

Metallurgy

Renewable industry

Machine Parts:

1. Feeding Inlet

2. Top Cover

3. Observation Hole

4. Screen Frame

5. Sealing Ring

6. Discharging

7. Wire Frame

8. Beam Ring

9. Bottom Frame

10. Pivot Assembly

11. Adjustment Block

12. Screen

13. Vibration Plate

14. Adjustable Bolt

15. Swing Body

16. Choke Spring

17. Main shaft assembly

18. Pulley

19. Base

20. Inspection Hole

21. Motor

Technical Parameters of 2000mm Food Grade Stainless Steel 316L Tumbler Screening Machine for Sea Salt Screening:

| Model | Screen Area (m²) | Layers of Screen | Motor Power (KW) |

| AM-600 | 0.28 | 1~5 (suggest 1~3) | 0.25 |

| AM-1000 | 0.72 | 1~5 (suggest 1~3) | 1.5 |

| AM-1200 | 1.10 | 1~5 (suggest 1~3) | 1.5 |

| AM-1500 | 1.80 | 1~5 (suggest 1~3) | 2.2 |

| AM-1800 | 2.30 | 1~5 (suggest 1~3) | 4.0 |

| AM-2000 | 2.60 | 1~5 (suggest 1~3) | 4.0 |

| AM-2300 | 3.90 | 1~5 (suggest 1~3) | 4.0 |

| AM-2600 | 5.30 | 1~5 (suggest 1~3) | 5.5 |

| AM-2900 | 6.40 | 1~5 (suggest 1~3) | 5.5 |

Contact: Ms. Magie

E-mail: sale@aarealmachine.com

magiecn@gmail.com

WhatsApp/WeChat: 0086-15637361027

Website: https://www.aarealmachine.com