Xinxiang Tongxin Machinery Co., Ltd. |

Metallurgy Double Screw Cone Mixer With Heating Metal Powder Stainless Steel

Introduction

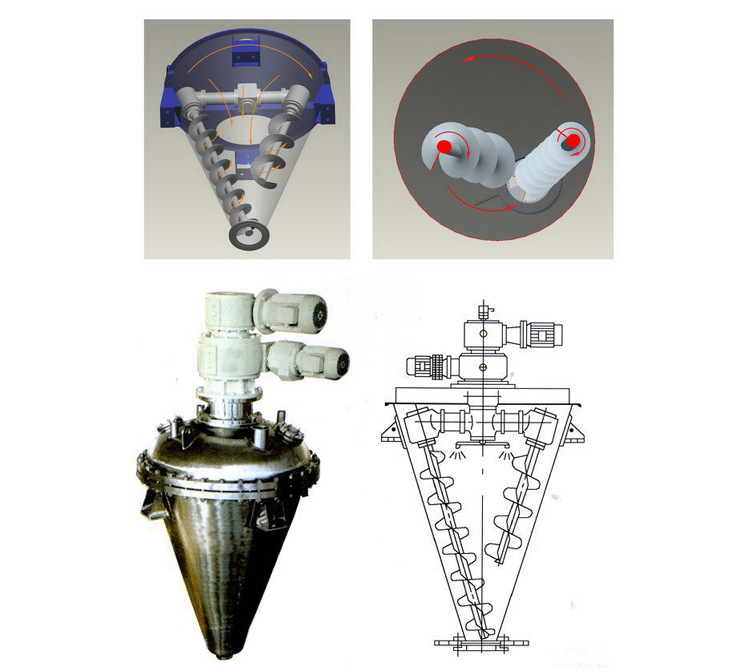

1. Mixing Method: Standard Twin-screw cone mixer has two stirring spirals. According to the requirements for production, you can choose single spiral (one long spiral), double spirals (a long and a short asymmetrical spirals) and three spirals (two short and one long symmetrical spirals);

2. Cooling and Heating System: Can equip with outer jacket for heating or cooling. Usually use water for cooling, steam/ thermal oil/ electric for heating;

3. Liquid-adding Mixing: Install liquid jet pipeline in the intermediate shaft of the mixer, connect the atomizing nozzle, which can adding liquid into the mixer; By selecting a specific material, you can add the acid and alkaline liquid material into the powder for mixing.

Features

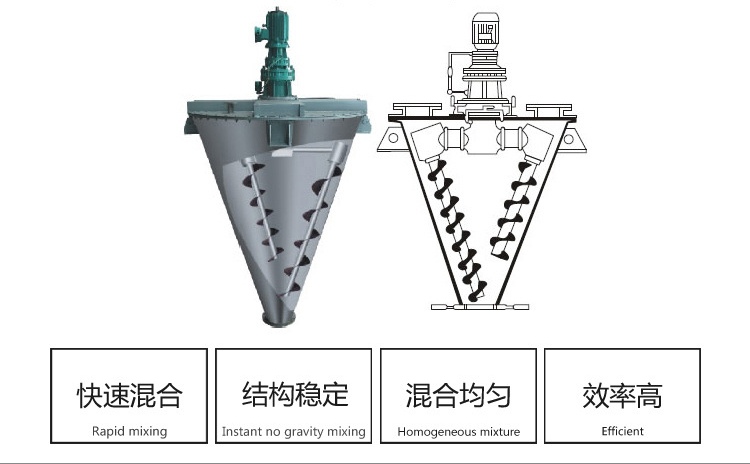

1. The cone cylinder adapts to the high requirement of no residue in the mixture;

2. The gentle stirring speed will not cause damage to the fragile materials;

3. The stirring action of the machine has a better coordination effect on the chemical reaction of the material.

Display of Detail

Apply in Industry

Double screw mixer is suitable for powder and powder, powder and liquid as well as liquid and liquid mixing. It is widely used in chemical, fertilizer, pesticides, dyes, breeding, food, pharmaceutical, health food and nuclear materials industries. This twin screw mixer has a good adaptability to coarse, fine and ultra-fine powder, fibers or flakes mixing.

Working Principle

The machine absorb foreign products advantage to design, because two barrels length are not same will not asymmetry ; when the mixer revolution, the raw material in barrel analysis and combination with different potential energy.

The raw material spread mixing alternately , with the time go on, the raw material will mixed very well.

Technical Parameters

| Specification | ZSHS-0.3 | ZSHS-0.5 | ZSHS-1 | ZSHS-2 | ZSHS-3 | ZSHS-4 | ZSHS-6 | ZSHS-10 | ZSHS-15 | ZSHS-20 | ZSHS-30 | ||||||||||

| Capacity (m3) | 0.3 | 0.5 | 1 | 2 | 3 | 4 | 6 | 10 | 15 | 20 | 30 | ||||||||||

| Output (t/h) | 0.3-1 | 0.5-1.5 | 2-2.5 | 2.5-5 | 4-7.5 | 5-10 | 7-15 | 12-20 | 18-30 | 20-40 | 30-60 | ||||||||||

| Power (kw) | 2.57 | 3.37 | 4.75 | 6.25 | 8.25 | 12.5 | 16.5 | 20.7 | 25 | 34 | 50.5 | ||||||||||

| Autorotation rate (r/min) | 143 | 143 | 57 | 57 | 57 | 53 | 53 | 53 | 53 | 53 | 53 | ||||||||||

| Revolution speed (r/min) | 2 | 2 | 2 | 2 | 2 | 1.6 | 1.6 | 1.3 | 1 | 1 | 1 | ||||||||||

| Loading coefficient | 0.6 | ||||||||||||||||||||

| Material particle size(mesh) | 20-1000 | ||||||||||||||||||||

| Mixing uniformity relative deviation(10min) | ≤1.5 | ||||||||||||||||||||

| Weight(kg) | 500 | 600 | 1200 | 1500 | 2100 | 2520 | 3150 | 3950 | 6500 | 8000 | 11600 | ||||||||||

Our Service

1. We provide 12 months quality warranty;

2. We have professional engineer team ensure to provide the most professional equipment;

3. Professional engineers team can choose the right equipment for you;

4. We can provide thorough after-sales service to ensure the proper use of machine.

5. We can provide OEM customization.

If you want to get more information of product, please contact us!