Guangzhou Weixing Automobile Fitting Co.,Ltd. |

|

Verified Suppliers

|

|

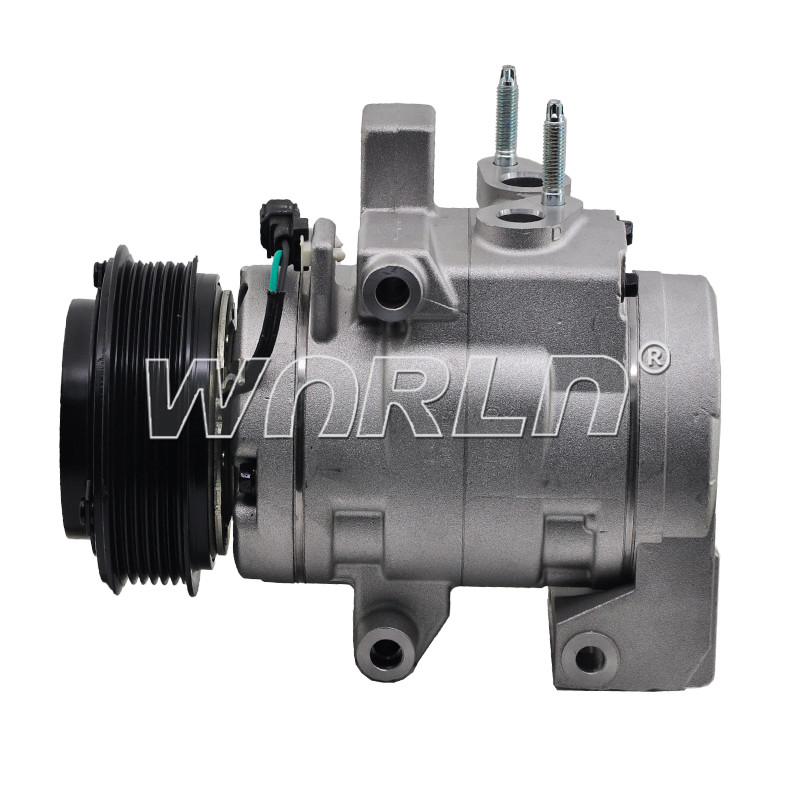

Car AirCon Compressor For Ford F150 For Lobo For Lincoln Mark 5.0 V8 BL3Z19703D WXFD056

Parameter:

| Car Make |

For Ford F150 For Lobo For Lincoln Mark 5.0 V8

|

| Compressor Model |

DKS20 6PK

|

| Voltage |

12V

|

| Refrigerant |

R134a

|

| Year Model |

2011-2017

|

| OE NO |

BL3Z19703D/BL3Z19703B

|

Installation and Testing of Car Air Conditioning Compressors

Car air conditioning compressors play a critical role in the functioning of the air conditioning system. They are responsible for compressing the refrigerant, which cools the air inside the vehicle. Proper installation and regular testing of the compressor are essential to ensure optimal performance and longevity. In this guide, we will discuss the steps involved in the installation and testing of car air conditioning compressors.

Installation:

1. Preparation: Before starting the installation, make sure you have all the necessary tools and equipment. This includes a wrench, torque wrench, refrigerant recovery machine, vacuum pump, manifold gauge set, and a new compressor.

2. Safety measures: Ensure that the vehicle's engine is turned off and the battery is disconnected to prevent any accidents. Take necessary precautions to avoid contact with the refrigerant.

3. Remove the old compressor: Begin by removing the old compressor. This involves disconnecting the refrigerant lines, electrical connections, and mounting bolts. Be sure to properly label and seal the disconnected refrigerant lines to avoid refrigerant leakage.

4. Install the new compressor: Place the new compressor in the correct position, aligning it with the mounting holes. Use a torque wrench to tighten the mounting bolts according to the manufacturer's specifications.

5. Connect refrigerant lines: Connect the refrigerant lines to the new compressor. Ensure that the connections are tight and leak-free. Use a torque wrench to tighten the fittings to the recommended torque specifications.

6. Electrical connections: Reconnect the electrical connections to the compressor. Double-check the connections to make sure they are secure.

Testing:

1. Vacuum testing: Connect the vacuum pump to the low-pressure side of the refrigerant system using a manifold gauge set. Evacuate the system by running the vacuum pump for the recommended amount of time specified by the manufacturer. Monitor the gauge readings to ensure that the system holds a vacuum.

2. Leak testing: Once the vacuum is achieved, close the valves on the manifold gauge set and turn off the vacuum pump. Allow the system to sit for a period of time and monitor the gauge readings. If the gauge readings remain stable, it indicates that the system is leak-free. Any significant drop in gauge readings would suggest a refrigerant leak and require further investigation.

3. Operational testing: With the vacuum still intact, proceed to recharge the system with the appropriate amount of refrigerant. Start the engine and turn on the air conditioning. Monitor the compressor operation, including the clutch engagement and refrigerant pressure on the gauge set. Ensure that the compressor operates smoothly and provides the desired cooling effect.

4. Performance testing: Measure the air temperature at the vents using a thermometer. It should be significantly lower than the ambient temperature. If the cooling effect is not satisfactory, it may indicate an issue with the compressor or other components that require further diagnosis.

In conclusion, the proper installation and regular testing of car air conditioning compressors are crucial for maintaining optimal performance. By following the steps outlined above, you can ensure a successful installation and reliable operation of the compressor.