Shenzhen K-Easy Electrical Automation Company Limited |

|

3 Years Warranty Frequency Converter, Frequency Inverter 50HZ/60HZ 220V 380V 480V vfd motor drive

| Model | Power Rating | Input Voltage | Output FREQ | Type |

|---|---|---|---|---|

| KD600 Series | 0.4kW-900kW | 208-240V / 380-480V 690V ±10% | 0.00-3200.00Hz | DC/AC to AC inverters |

Thanks to sophisticated engineers, scientific producing workmanship, rigorous quality control systems and management team, K-Drive frequency inverters are equipped with advanced features, some of which are listed as below:

01. Starting torque: 180% at 0.5Hz (V/f pattern, SVC pattern);

02. Speed adjustable range: 1: 100 (V/f pattern, SVC pattern);

03. Speed accuracy: +/-0.5% (V/f pattern), +/-0.2% (SVC pattern);

04. Over load capability: 150% 1minute, 180% 10seconds;

05. Abundant frequency command sources;

06. Diverse input and output terminals;

07. Ambient temperature: -10°C~50°C;

08. High precise torque constraint, process PID control, multi-speed control, contracting brake control, field weakening control, all sides protection, etc;

09. Online and offline auto-tuning of motor parameters can both performed;

10. Extremely short-time acceleration can be performed without any trip, such as 0.1s or 0s from 0Hz to 50Hz;

| Mains Supply (L1/L,L2,L3/N) | |

|---|---|

| Supply voltage | 208-240V ±10% 380-480V 690V ±10% |

| Power source frequency | 50/60Hz ± 5% |

| Displacement power factor (cos φ) | (>0.98) |

| Output Data (U, V, W) | |

|---|---|

| Output voltage / frequency | 0-100% of supply voltage / 0.00-600.00Hz or customized |

| Ramp time | 0.01-60000s |

Note: 150% current can be provided for 1 minute, 180% for 10 seconds. Higher overload rating is achieved by oversizing the drive.

| Digital Input | |

|---|---|

| Programmable digital inputs | 5 |

| Logic | NPN or PNP |

| Voltage level | 22 - 26V |

| Analog Input | |

| Analog inputs | 2 |

| Modes | Voltage or current |

| Level | 0 to +10V, 0/4 to 20 mA (scalable) |

| Automatic correction | YES |

| Relay Output | |

| Programmable relay outputs | 1 |

| RA - RB / TA - TB | Normally close |

| RA - RC / TA - TC | Normally open |

| Contact capacitance | 250 V AC / 3A, 30 V DC / 3 A |

| Terminal 485 Interface | |

| 485+ / 485- | Rate: 4800/9600/19200/38400/57600/115200 bps Max. distance: 500 m |

| GND | Isolated from COM |

| Ambient | |

| Vibration | Less than 5.9 m/s² (0.6g) |

| Humidity | Relative humidity 5% - 95 %. No condensation |

| Corrosive environment | 3C3 |

| Ambient temperature | -10 ºC - 50 ºC |

| Altitude | 0 - 2,000 m |

| Rated output current derated 1% every 100 m above 1,000 m | |

| Storage temperature | -40 - +70 ºC |

| Efficiency | Efficiency At rated amps: ≥93% |

| IP grade | IP20 |

| Cooling method | Forced air cooling |

| Fieldbus Communication | |

| Modbus RTU, Modbus ASCII | Built-in |

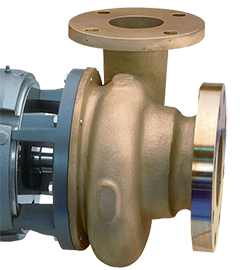

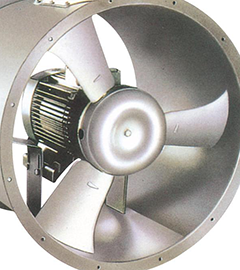

KD600 drives are economical series at K-Drive. They offer V/f control, including voltage and frequency separated control, adaptable to various industrial applications if sensor-less vector control is not required, including printing machines, packaging machines, pumps, fans and blowers, etc.

|  |  |

| Conveyors | Centrifuges | Food processing Machinery |

|  |  |

| Pumps | Fans | More … |

In the trend of advocating smart and simple industrial automation, environmentally friendly products, value-added solutions, K-Drive, as one of the world's leading drive manufacturers aggressively investing in R&D, production, and continuous quality improvement, is well positioned to provide its customers with technology-driven, performance-outstanding products such as VFDs, wind power converters, servo drives, HEV/EV drives, helping its customers save energy and increase industrial productivity with sustainability on the one hand, and enhancing their entire value-chain quality, delivery, and services on the other hand.

In production, rigorous quality control is implemented on components, circuit boards, and the finished goods, assuring products without defects.

| Performance | Common brands | K-Drive |

|---|---|---|

| Applicable motors | Asynchronous motors | Asynchronous /synchronous motors |

| Starting torque | 2.0Hz, 150% (sensor-less vector control) 0Hz, 180% (closed-loop vector control) | 0.5Hz, 180% (sensor-less vector control) 0Hz, 200% (closed-loop vector control) |

| Speed adjustable range | 1:100 (SVC), 1:1000 (VC) | 1:200 (SVC), 1:1000 (VC) |

| Ambient temperature (no derating required) | -10-40ºC | -10-50ºC (for most of the models) |

| Rated input voltage | 208VAC-400VAC | 208VAC-480VAC |

| Communication | Modbus RTU//ASCII | Modbus RTU//ASCII Profibus-DP, CANopen, etc. |

| Position control (fixed length, or angular positioning) | × | √ |

| Field weakening control | × | √ |

| Autotune online | Online | Online & Offline |

| Short-time ramp-up | Trip | No trip |

| Customized features (software and/or hardware) | Unprocurable or no experience | Procurable with rich experience |

Please leave us an inquiry for more details of our frequency inverters, like information of the model numbers, technical data, applicable application, pricing, distributor policy, lead time and/or customized functionality.

VVVF stands for Variable Voltage Variable Frequency, which is a type of motor control used in industrial applications. The components of a VVVF system typically include:

Power supply: This provides the necessary electrical power to the system.

Inverter: This converts the DC power from the power supply into AC power with variable voltage and frequency.

Control unit: This is the brain of the VVVF system and manages the operation of the motor.

Motor: This is the device that converts electrical energy into mechanical energy.

Sensors: These are used to monitor the motor's speed and position and provide feedback to the control unit.

User interface: This allows the user to interact with the VVVF system and adjust its settings.

Together, these components work together to provide precise and efficient control of industrial motors.