Foshan Jinxinsheng Vacuum Equipment Co., Ltd. |

|

Verified Suppliers

|

|

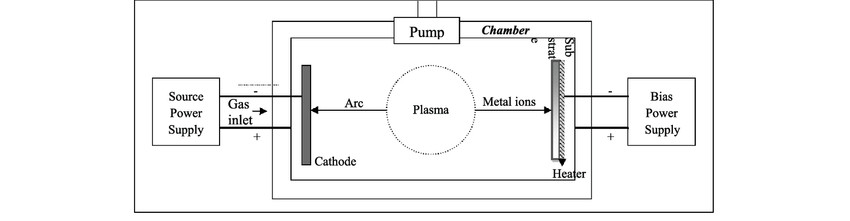

Working principle: Cathodic arc deposition or Arc-PVD is a physical vapor deposition technique in which an electric arc is used to vaporize material from a cathode target. The vaporized material then condenses on a substrate, forming a thin film. The technique can be used to deposit metallic, ceramic, and composite films.

Application: door handle, door hinge, sanitary ware, tableware, cellphone accessory, stainless steel furniture, stainless steel sheet, ceramic tile, glass crystal, bags and suitcases hardware, watch, stainless steel signboard, etc.

Color: gold, silver, rose gold, blue, gray, black, rainbow.

Film feature: strong adhesion, high hardness, gorgeous decorating effect.

Green process: no harmful gas, no waste water, no waste material.

| Multi-Arc Coating Equipment Model | |||||

| Model | JXS-1010 | JXS-1215 | JXS-1820 | JXS-2336 | JXS-2345 |

| Chamber(mm) | D1000×H1000 | D1200×H1500 | D1800×H2000 | D2300×H3600 | D2300×H4500 |

| Structure | Vertical door structure, pumping system and water cooling system | ||||

| Vacuum System | Diffusion Pump or Molecular Pump + Hold Pump + Rough Pump + Roots Pump | ||||

| Ultimate Pressure | 1.0- 6.0×10-4Pa, Non-loading cooling | ||||

| Temp. | Normal temp- 300°C to 450°C - 600°C, controlled and adjusted(PID temp. control) | ||||

| Gas | Ar, N2,O2, C2H2,etc. | ||||

| Cooling | Water cooling circulation, industrial cooling tower or industrial water chiller(refrigerating machine) or cryogenic system.(customers provide) | ||||

| Controlling | Manual, semi-auto, full auto | ||||

| Air Pressure | 0.5-0.8MPa | ||||

| Water Temp. | ≤25°C | ||||

| Water Pressure | ≥0.2MPa | ||||

| Total Power | 25-65KW | 65-105KW | 85-115KW | 95-145KW | 130-180KW |

| Output Frequency | 380V, 50Hz(Custom made) | ||||

| Occupied Area | 35~50m² | 55~95m² | 75~105m² | 125~175m² | 135~205m² |

| Remark | Customization | ||||

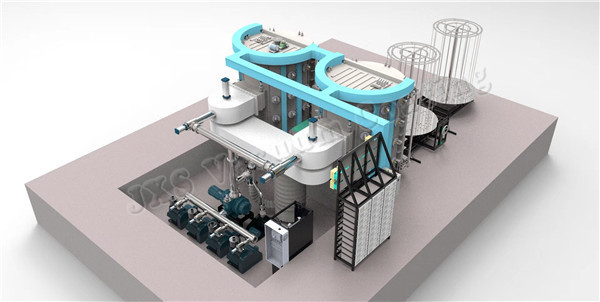

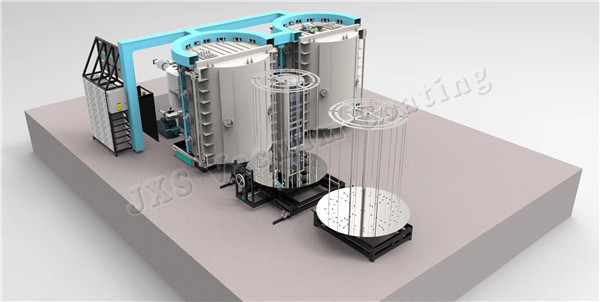

3D Effect

PVD Coating Film Advantages

I)Strong Adhesion Film For Longer Using Life

II)Decoration For Higher Selling Value

III)Decorative Coating Colors For Better Viewing Feeling

Why choose JXS Vacuum?

I)Custom Made PVD Coating Machine

II)1 Year Warranty

III)7 Days Free Installation & Training

IV)On Line Or On-The-Spot After-Sales Service

V)Offer PVD Coating Machine Spare Part & Consumable

Packing and Shipping

FAQ

.

Q1: How about your company?

A1: We are a leading manufacturer and provider of total integrated

supply chain solutions for vacuum coating machine.

Q2: How about the quality control about our products?

A2: We have the ISO9001 QMS-Quality Management System.

Q3: Do you provide after-sales service?

A3: After-sales problems shall be solved on line within 48 hours.

Long-term product solution and remote technical support is

provided.

Q4: What about the payment terms?

A4: T/T and it is also flexible according to different types of

machine.

Q5: About the package?

A5: Nude packing or wooden case carton container.

Q6: Do you provide the second-hand machine?

A6: Yes. We also provide second-hand machine, you can provide your

requirements to our salesman.

Q7: What is lead time of PVD electro colouring system?

A7: About 60 working days.

A8: Do you teach all PVD colouring details?

A8: Yes, we will teach you in your factory.

A9: Do you have quality guarantee for PVD electro colouring system?

A9: 1 year guarantee and lifetime technical support.

A10: If we buy the machine how can we install the machine in my

factory and you can't leave the country due to the COVID-19 ?

A10: We can send you the Equipment Installation Guide and instruct

you to install by online video.