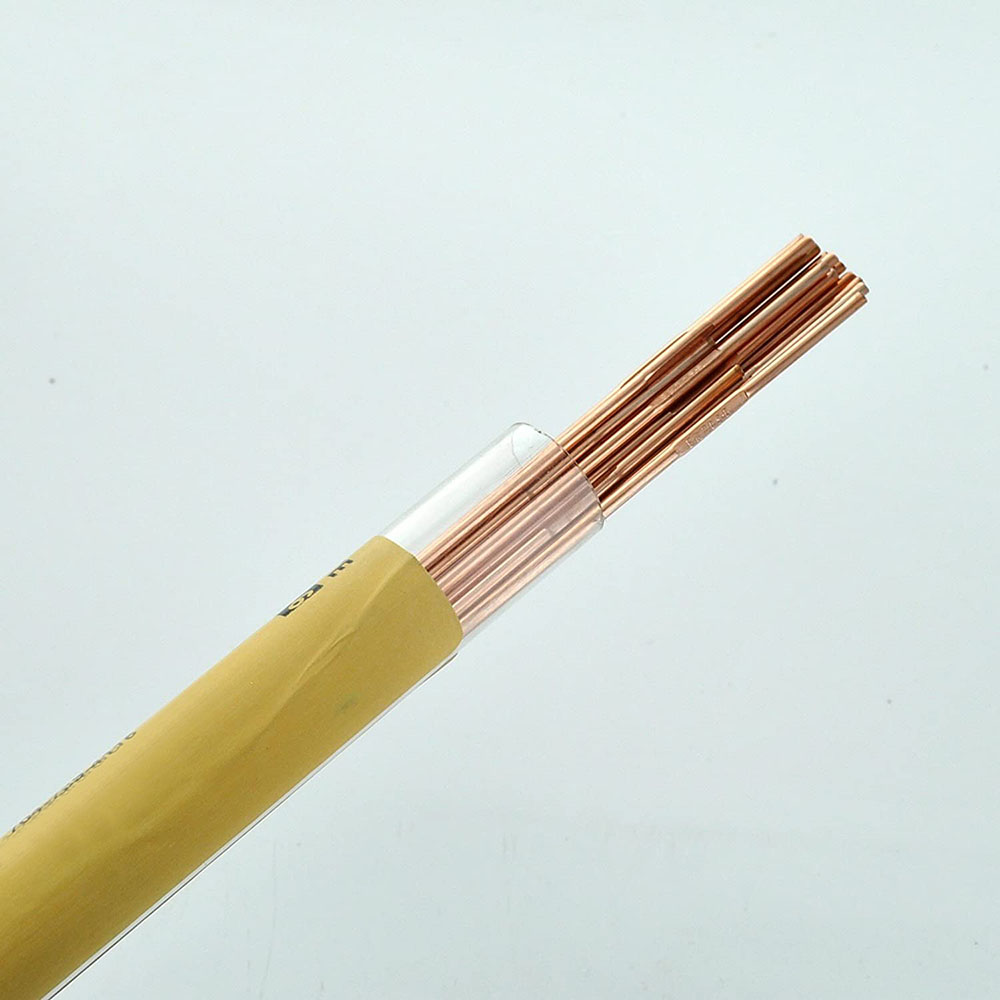

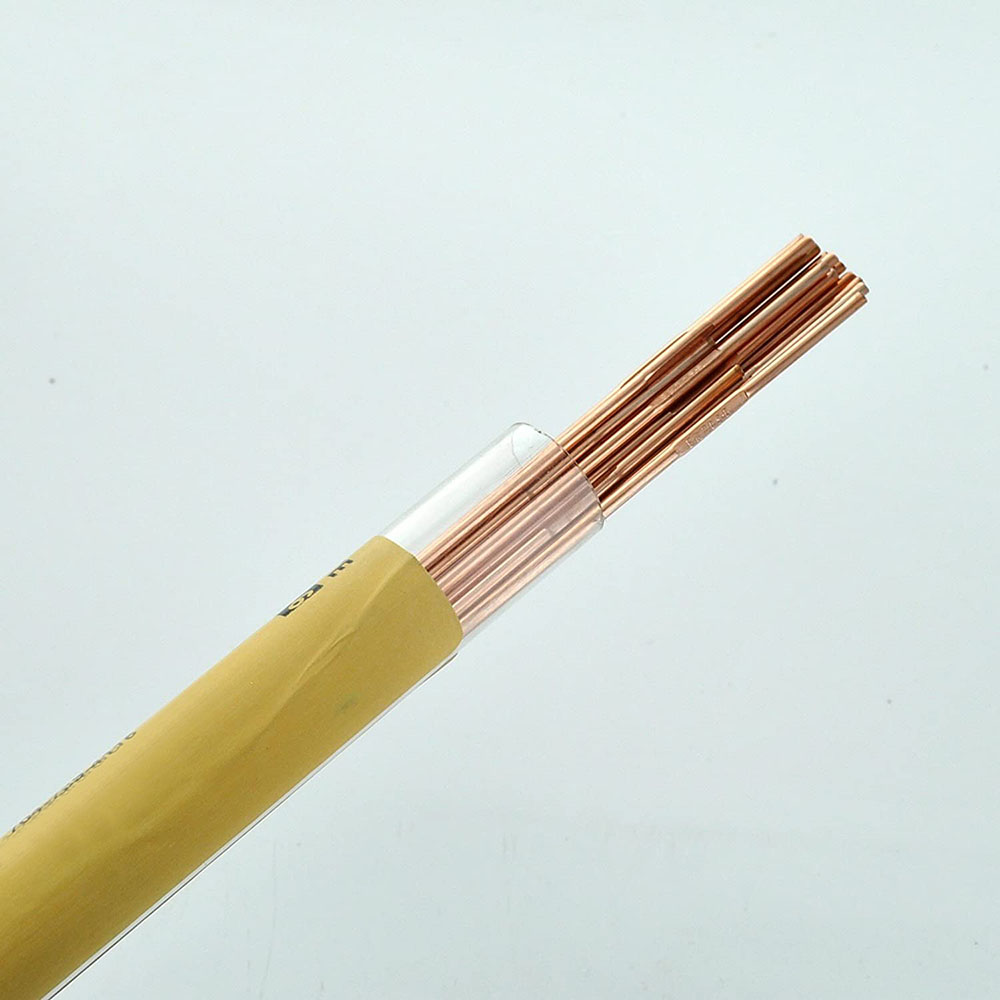

Copper coated steel welding wire ER70S-6

ER70S-6 is a kind of mild steel copper coated welding wire,

suitable for 100% CO2 and Argon& CO2 mixed gas protective

welding with

stable feasibility, good welding seams, less spatters and excellent

welding process properties.

Application:

Used to weld ship building steel(A,B,D,E,A36,D36,E36)and equivalent

mild steel or 550Mpa grade mild alloy steel, such as container

building, construction machine, railway construction, pressure

vessel for semi-auto or automatic gas shielded welding.

ER70S-6 MIG WIRE Packing:

PackagingWire SizePackageNet Weightφ1.6~4.0(mm)5kg/tube.

10kg/tube5kg, 10kg

Wire Chemical Composition

(%)CMnSiPSCrNiCu0.06~0.151.40~1.851.80~1.15≤0.025≤0.035--≤0.50

Deposited Metal Mechanical PropertiesYield StrengthTensile

StrengthElongationAKV Imapact

Energyσ0.2(Mpa)σb(Mpa)δ5%(J)(-40℃)≥420

≥500≥22≥90Diameter of wire(mm) Wleding

Current(A)Φ1.0Φ1.2Φ1.4Φ1.640~14050~22080~350120~450

Matters needing attention:

1.Wire into the plant must be stored in dry conditions, can not

open wire reel waterproof package.

2.Welding shall be removed before welding surface oil, rust,water

and other impurities.

3.The CO2 gas protection, CO2gas purity 99.98%.

4.CO2 welding protective gas flow rate should be controlled at

20~25L/min.

5.Wire extension length should be controlled in the range of

15~25mm.

6.Preheatig before welding to weld 150℃~300℃, 700℃~740℃ tempering

treatment only after.