Mitech CO.,LTD. |

|

Mhvs Series Vickers Hardness Tester Digital Durable Accurate Measurement

Mitech MHVS series digital vickers hardness tester, based on the principle that positive quadrangular pyramid diamond indenter presses the surface of the sample to produce indentation.By measuring the diagonal length of the indentation to achieve the measurement of the hardness of the material can be for small specimens, thin specimens, surface coating, heat treatment of the workpiece surface Vickers hardness test. With stable performance, strong structure, high reliability, simple operation, adopt digital display and high magnification optical measurement system, adjust the cold light source, photoelectric sensing technology and computer-aided means it has a powerful function. It is widely used in the fields of metal processing, electronics industry, mold parts, watch manufacturing, engineering quality inspection and so on. It is an ideal hardness tester for material research and testing.

| Model | MHVS-5 | MHVS-10 | MHVS-30 | MHVS-50 |

| Test force | 2.94N,4.9N, 9.8N,19.6N,29.4N,49N | 2.94N,4.9N,9.8N, 29.4N,49N,98N | 9.8N,29.4N ,49N ,98N,196N,294 N | 9.8N,49N, 98N,196N, 294N,490 N |

| Measurement range | 40HV0.3~2500HV5 | 8HV0.3~2500HV10 | 10HV2~2500HV30 | 40HV~ 2500HV |

| Hardness symbol | HV0.3,HV0.5, HV1,HV2,HV3,HV5 | HV0.3 ,HV0.5,HV1, HV3,HV5,HV10 |

HV10,HV20,HV30 | HV1,HV5, HV10, HV20,HV30,HV50 |

| The conversion mode of the head and the objective lens | Manual operation | Manual operation | Manual operation | Manual operation |

| Loading and unloading mode | Automatic operation | Automatic operation | Automatic operation | Automatic operation |

| Magnification of measuring microscope | 200x(testing) 100x(observing) | 200x(testing) 100x(observing) | 200x(testing) 100x(observing) | 200x(testing) 100x(observing) |

| Minimum detection unit | 0.01μm | 0.01μm | 0.01μm | 0.01μm |

| Maximum height of applicable materials | 160mm | 160mm | 160mm | 160mm |

| Test to secure the load time | 0~60s | 0~60s | 0~60s | 0~60s |

| Maximum distance from the center of the head to the machine wall | 135mm | 135mm | 135mm | 135mm |

| Display | LCD digital display | LCD digital display | LCD digital display | LCD digital display |

| Power supply | AC220V/50Hz | AC220V/50Hz | AC220V/50Hz | AC220V/50Hz |

| Dimension of Exterior | 540*220*650mm | 540*220*650mm | 540*220*650mm | 540*220*650mm |

| Machine weight | 40kg | 40kg | 40kg | 40kg |

Working Principle

Micro-Vickers (or Knoop) hardness test principle is that put the provisions of the positive pyramid diamond indenter into the sample surface(with fixed experimental force) and maintain a certain length (holding), and then unloading. Finally, there is a positive quadrangular pyramid or kenup indentation with a square surface on the surface of the specimen. Then we can attain the area of indentation via measuring the length of the diagonal by a micrometer eyepiece. Then the corresponding Vickers (or Knoop) hardness values are obtained.

Working Principle Figure

Figure 2 :Appearance structure

l.main body 2.Lift screw 3.Test bench 4.Pressure head screw 5.20X objective lens 6.Camera, measuring conversion lever 7.Camera interface cover8.Indenter 9.Top cover 10.10X objective lens 11.Back cover 12.Lamp holder housing screws 13.Lighting lampholders 14.Digital micrometer eyepiece 15.Display screen 16.Horizontal adjustment screw 17.Operation panel 18.Power outlet 19.Power switch 20.Panel printer

21.RS232 interface

Figure 3 main interface display diagram

| Contrast hardness: show the corresponding values of other hardness units; | Test force: test force of instrument loading; |

| D1 (D2): indentation diagonal length; | Holding time: test force holding time; |

| Test temperature: ambient temperature; | Test times: show the number of shocks that have been completed; |

| Test domain values: preset hardness values upper and lower limits; | Average value: multiple measurements to remove the maximum and minimum of the average value; |

| Repeatability: the difference between the maximum and minimum indentation averages. |

| OK | Confirmation key | ↑ | Direction and light source adjusting key |

| ESC | Return key | ↓ | Direction and light source adjusting key |

| CLR | Set zero key | ← | Direction and objective switch key |

| SET | Main menu key | → | Direction and objective switch key |

| DEL | Delete key | ↓ | Start key |

| PRT | Print key | DWL | Holding time select key |

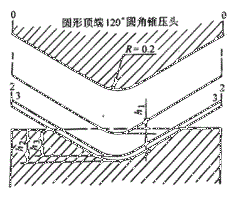

Punch on the the prepared workbench,The specific dimensions are shown in Figure 4.

Figure 4 working console

Remove the outer box, take out the hardness of the host and accessories box.The hardness gauge is placed on the special worktable, then the horizontal adjusting screw is removed from the accessories box, and the screw is placed at the bottom of the hardness tester and adjusted to the level.The tied on the rotating wheel to remove the weeds,loosen the screw on the protecting sleeve of the screw rod, put down the lifting screw, and take out the protecting cover of the screw rod,clean up the antirust oil on the lifting screw, apply a small amount of thin oil to lubricate, and then install a protective cover for the screw rod.Rotate the screw, remove the pad between the lifting screw and the indenter cover, and remove the test stand in the accessory box and install it on the lifting screw. And then turn the rotary knob to make the screw down and ensure that the screw can be successfully through the special workstations open the hole.

Remove the white gauze between the main body head and the indenter, open the top cover, and remove the straps that are tied between the cam and the lever.Open the back cover and remove the white gauze tied between the boom and the fork, and then install the 3 weights in the accessory box in the order from small to large, and finally restore the cover and the back cover.