Mitech CO.,LTD. |

|

Mitech MH310 Leeb Hardness Tester with intergrated printer on site different from ultrasonic hardness tester

Advantages

Wide measuring range. Based on the principle of Leeb hardness testing theory. It can measure the Leeb hardness of all metallic materials.

Large screen LCD, showing all functions and parameters. With EL background light.

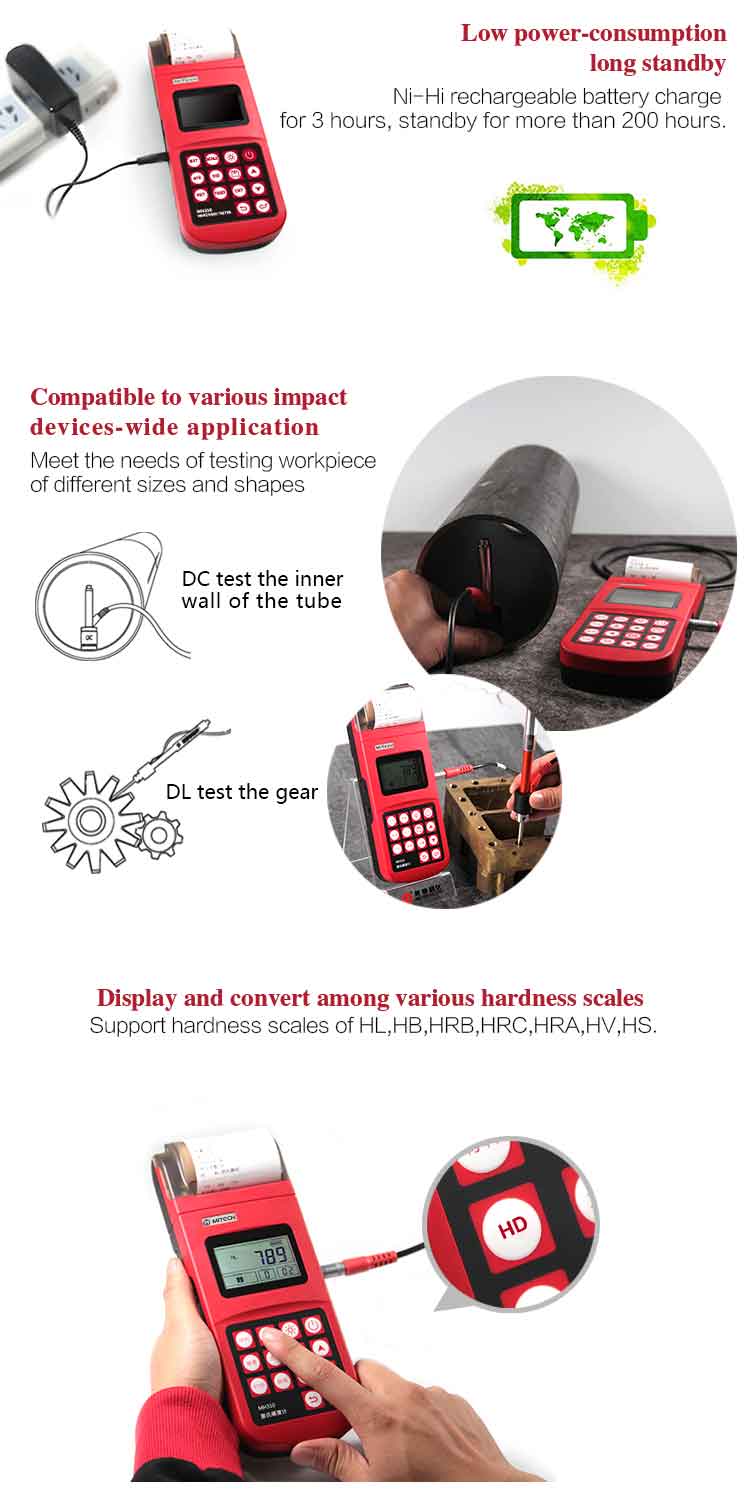

Seven impact devices are available for special application. Automatically identify the type of impact devices.

Test at any angle, even upside down.

Direct display of hardness scales HRB, HRC, HRA, HV, HB, HS, HL.

Large memory could store 100 groups (Relative to average times 32~1 ) information including single measured value, mean value, impact direction, impact times, material and hardness scale etc.

Battery information showing the rest capacity of the battery and the charge status.

User calibration function.

Software to connect to PC via USB port.

Thermal printer integrated, convenient for in field printing.

NI-MH rechargeable battery as the power source. Charge circuit integrated inside the instrument. Continuous working period of no less than 150 hours (EL off and no printing).

Auto power off to save energy.

Application

Parts of the Main body

1 Socket of impact device 2 Socket of USB 3 LOGO

4 Paper compartment cover 5 LCD display 6 Keypad

7 Battery switch 8 Power jack 9 Serial Number

10 Product label 11 Battery compartment cover

Instrument Preparation and Inspection

Verification of the instrument is by using standard test block. The error and repeatability of displayed value should be within the regulation of Appendix table 2. The instrument and impact device must be calibrated using a standard hardness block before use as the first time, or having not been used for a long time, or having reset the instrument system.