AG SONIC TECHNOLOGY LIMITED |

|

Automatic Multistage Cleaning Systems Multiple Tanks Having

Ultrasonic Jet Spray Rotating Basket Dunking

Engine Cylinder Filter Automotive Ultrasonic Cleaner Used Car

Working Shop

Engine Parts Cleaning, Car Engine Parts Cleaning, Truck Engine

Parts Cleaning, Motor Bike Engine Parts Cleaning.

Ultrasonic cleaner for engine parts are available in different size

and versions that are suitable for the variety of needs – including

the clean up of your car engine parts.

Here we provide our best reviews on top selling ultrasonic cleaners

for car engine parts. Just check them out and get one as per your

requirement.

Auto Parts Cleaning machine

We are manufacturing and supplying of Automotive Ultrasonic

Cleaners. We offer a wide range of ultrasonic cleaners. These are

Single or Multistage Ultrasonic Cleaners, which are both manually

operated & fully automated systems. Further, the machine is

widely used and appreciated by our clients due to its professional

dependability and user friendliness.

Ultrasonic Cleaning system Design:

Considerations in the design of any cleaning system include the

contaminants on the part(s), the required cleanliness level, the

geometry and material of the part(s), the quantity to be processed,

and the previous system design and layout (if applicable). The part

geometry, production rate, and cleaning time required will

determine the size of the cleaning system, once the overall process

has been decided

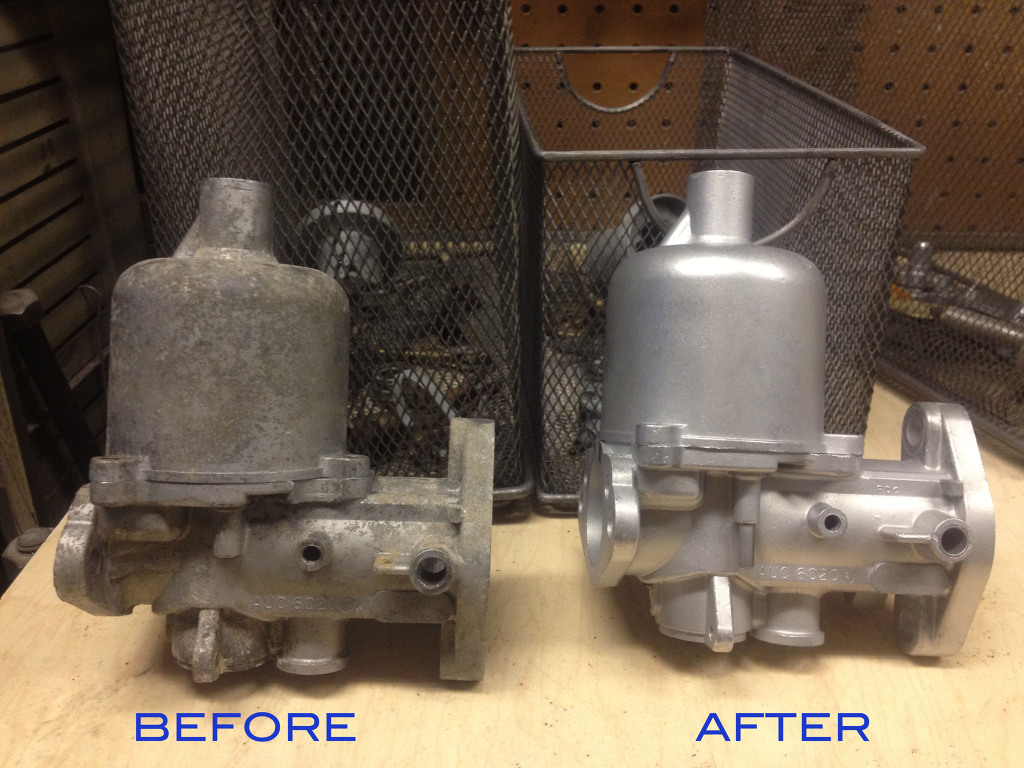

The cleaning scope of AG Engine block ultrasonic cleaning machine

Suitable for all types of engine parts

AG engine block ultrasonic cleaning machine effectively and

thoroughly clean all types of engine parts

01: Automotive: thoroughly removes carbon deposits, grease, and other types of

dirty and contaminants from carburetor, exhaust manifolds, cylinder

blocks, 2-stroke and 4 stroke motorcycle engines, snow machines,

ATV cylinders and heads, and more.

02: Marine: Suitable for inboard and outboard motors, the cleaning chemistry

is both thorough and gentle on the aluminum parts reducing the risk

of future corrosion

03: Aircraft: The high performance demands of aircraft engines establish the

need for an intensive cleaning process that will restore the engine

part to near original condition, our engine block ultrasonic

cleaning machine easily, thoroughly, and safely clean both large

and small parts, turbine blades, fuel nozzles, generator

components, brakes and other parts that require periodic cleaning

are all effectively and thoroughly cleaned using the ultrasonic

cleaning process

Multi Stage Aqueous Ultrasonic Cleaners

Why Use Ultrasonic Cleaner

The current practice involves use of chlorinated solvents like TCE,

PCE etc. that are the choice solvent used through the industries in

their cleaning process. Aqueous Ultrasonic Cleaning System are very

popular due to their good solvency, lower heat of evaporation, high

or absence of flash point, non-corrosive nature, relative stability

& compatibility with metals & glass. However all

chlorinated solvents are hazardous to human health &

environment.Some chlorinated solvents are suspected to cause cancer

(Carcinogenic) over prolong exposure. Being hazardous to health

their usage has come under intense investigation from pollution

control & health authorities & has already been banned by

developed countries. This has lead to shift to alternative cleaning

technology based on aqueous solvents.

We are one of the leading manufacturers and suppliers of an array

of Semi Automatic Cleaning Systems. Known for their low noise and

smooth operation, these are widely considered among the customers

we have. Available in different types depending upon the production

rate, these conveyors are acknowledged for high load bearing

capacity and sturdy construction. We also undertake customization

of this range to meet the specific requirements of our clients.

Depending on the cleaning level required the number of cleaning

stages are decided.

We expertise in Multistage Cleaning Syst

ems with Multiple tanks having Ultrasonic, Jet Spray, Rotating

Basket, Dunking, Automatic Material Transfer, Handling system,

Filtration, Oil Skimming & Drying as various options. Such

machine are used for cleaning of Mold Inserts, Auto-Ancillary

Parts, Medical Surgical tools and various other types of

components.

Multistage Ultrasonic Cleaning Machine with the ultrasonic power.

The product comes with digital timer and controlled thermostat. We

offer a unique range of ultrasonic cleaning machines that are

highly demanded for their excellent performance and low

maintenance. Ultrasonic cleaner is majorly used in cleaning

surgical instruments, automobile industry, ancillary industrial

products, stationary manufacturers and many more.

Here is the work cycle :

•Ultrasonic cleaning in warm alkaline detergent

•Rinsing in cold running water

• Rinsing with ultrasonics in warm demineralized water

•Drying in warm pressure-ventilated air

Specifications:

•Energy consumption is: 12-14 Kw

•Long: 9 mm

•Diameter: 0.9 mm

Additional Information:

•Production Capacity: Custom Built

•Delivery Time: 4 Weeks

•Packaging Details: Wooden Packing

How the System Operates:

The system operates in the following manner:

The cover is opened and the batch of parts is placed onto the basket rest. Dripping liquids are directed back to the ultrasonic cleaning tank