Joiner Machinery Co., Ltd. |

|

Verified Suppliers

|

98 MVPLUS Extruder Screw Elements With High Corrsion and Wear Resistance

| Screw Design | Double-Screw |  |

| Hardness | 58-60HRC | |

| Brand Name | Jioner | |

| Surface Treatment | Polishing/Sand Blasting | |

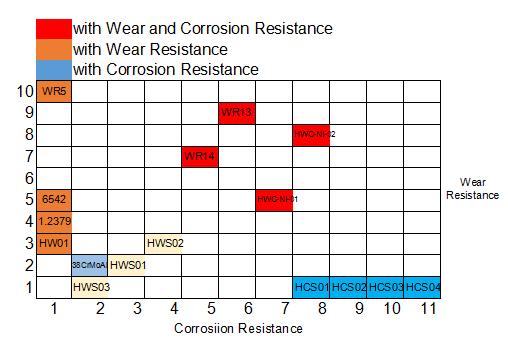

| Materials | SAM10/SAM39/WR5/WR14/SEA6150 | |

| Place of Origin | Sichuan , China | |

| Warranty | 1 Years | |

| Screw Range | Φ 15.6 - Φ 430mm | |

| Suit For | Pharmaceuticals Extrusion Chemical Extrusion Food Extrusion Powder Coating Extrusion | |

(2 Coperion ZSK98 MVPLUS Extruder Screw Elements Materials For Choice:

(3)Coperion ZSK98 MVPLUS Extruder Screw Elements

| Special Screw Segment | Convey Screw Element |

| Mixing Screw Element | Kneading Block and disk |

| Transition Screw Element | Screw Element for Side Feeder |

| Screw Element for Side Feeder |

(4)Standerd Screw Element and Kneading Block

(5)98 MVPLUS Extruder Screw Elements Manufacturing procedure

(6)Other Products of Our Company

|  |  |

| Shaft | Screw Element | Barrel |

2. Heat treatment by Ourself

As we all know, heat treatment is very important in the screw

production process. In order to ensure the quality of products,

Joiner has purchased professional heat treatment equipment to

produce, so that we can control the construction process by

ourselves. In China, we are the only company that does heat

treatment by ourselves, and the heat treatment of screw components

made by Nanjing factory is processed by outsiders, so the quality

of products can not be completely guarantee.

(7)Processing Route Tracking List

Each process requires inspection . The production personnel shall

check whether it’s meet the requirements of the drawings by

themself. If it meets the requirements of the drawings,it shall be

submitted to the inspection personnel for inspection. After pass

the inspection to the next process personnel processing.

(7) 98 MVPLUS Extruder Screw Elements Packing & Delivery

Packing Details : Standard packing for Joiner Extruder twin screw extruder

parts/extruder spare parts

Delivery Time: Shipped in 30 days after payment for extruder screw and barrel.

To product antirust processing ,and then use the paper

package,bubble,fixed in the wooden case,after confirm the delivery.

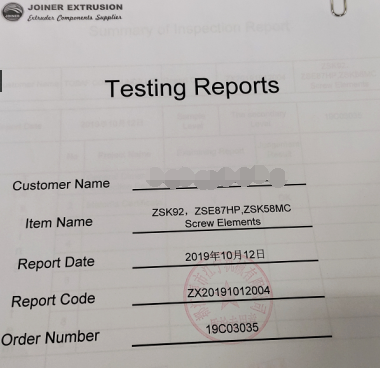

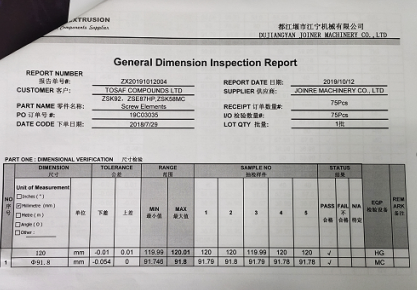

8. 98 MVPLUS Extruder Screw Elements Testing Reports for Our customer

We will send Inspection reports for every our customer.

1.General Dimension Inspection Report

2. Material certificate for customer.

|  |