Joiner Machinery Co., Ltd. |

|

Verified Suppliers

|

|

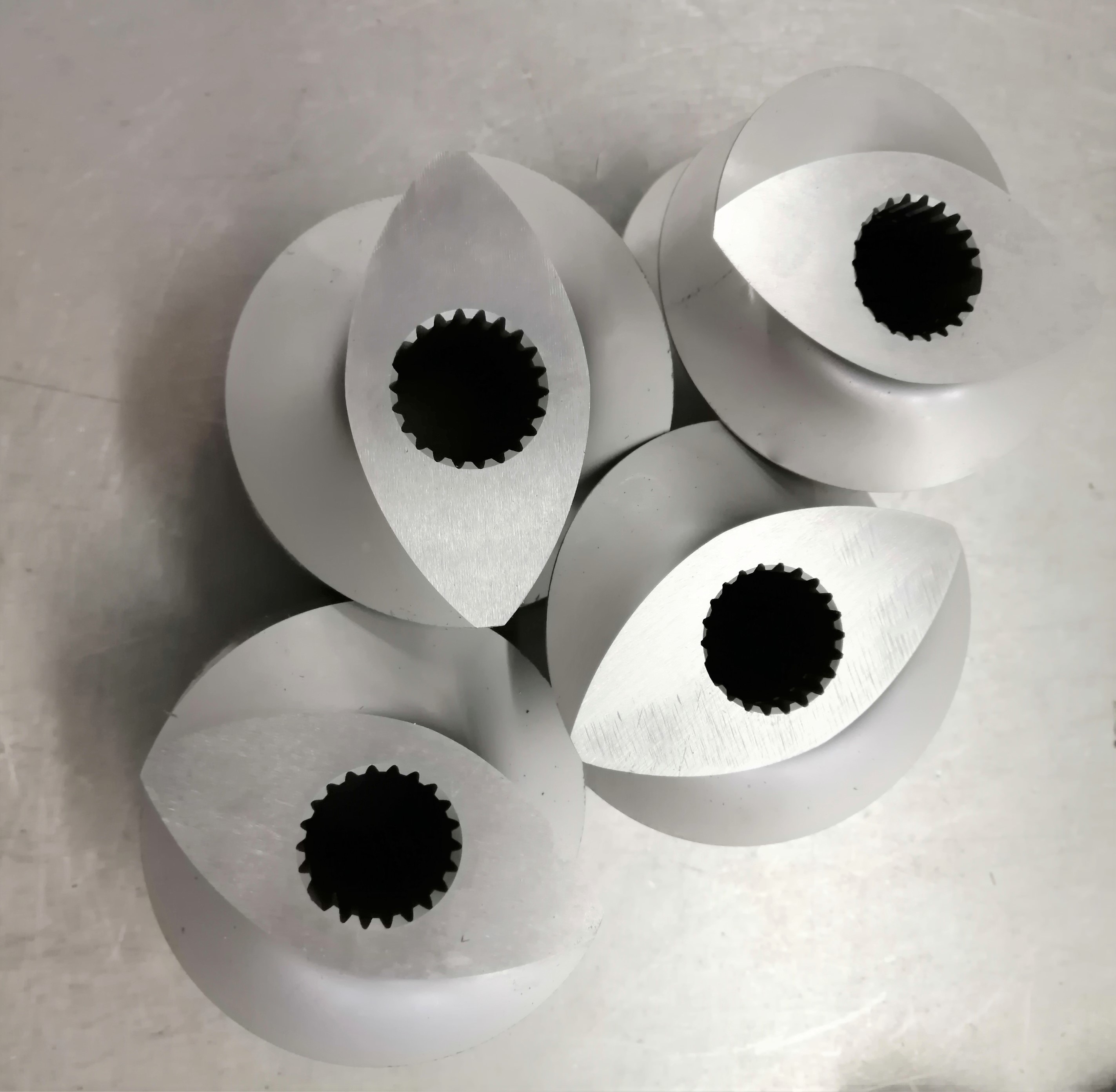

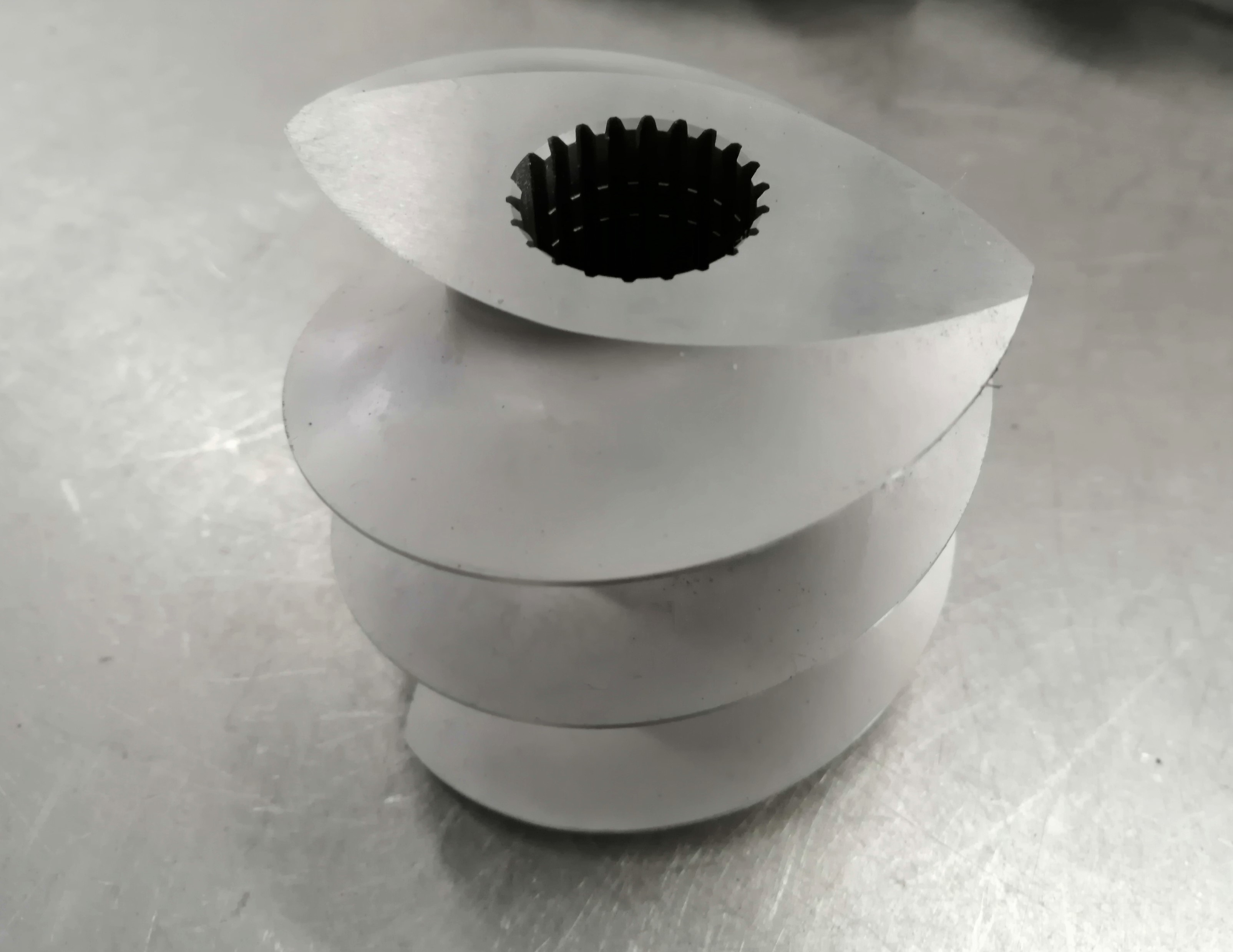

Durable CWJ70 High Efficiency Double Flighted 60HRC Extruder Screw Elements

| Screw Design | Double-Screw |  |

| Hardness | 58-60HRC | |

| Brand Name | Jioner | |

| Surface Treatment | Sand Blasting | |

| Materials | WR5 | |

| Tooth | 22 | |

| Pression angle | 30° | |

| Model | 45/60 | |

Suit For

| Feeding | |

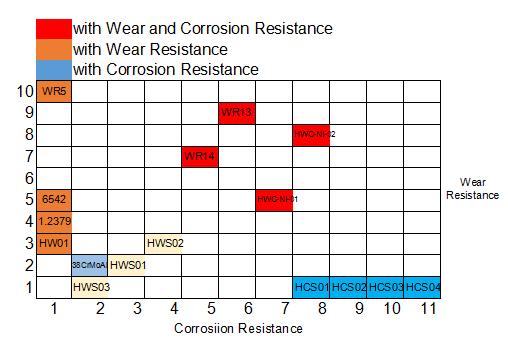

2. Materials:

For wear application:

* Normal material: HW01,HW02,HW03

* PM-HIP material: HWA

* Stainless Steel: HWS01, HWS02, HWS03

For corrosion application:

* Normal material: HC01

* Stainless Steel: HCS01, HCS02, HCS03, HCS04

For wear and corrosion application:

* PM-HIP material: HWC01, HWC02

* Ni-HIP material: HWC-Ni-01, HWC-Ni-02

3. Making process

4. Heat treatment

heat treatment is very important in the screw production process. In order to ensure the quality of products, Joiner has purchased professional heat treatment equipment to produce, so that we can control the construction process by ourselves.

5. Packing:

According to your order quantities and products sizes to choose wooden boxes or cartons to pack:

a. Rust-proof oil processing,

b. Oiled paper packages,

c. Bubble wrap package,

d. Special foam packaging,

e. Packing,

f. Sealing.

6. Testing Reports

We will send Inspection reports for every our customer.

a.General Dimension Inspection Report

b. Material certificate for customer.

7. FRQ

1. Q: Are you a factory or trading company?

----A: A factory

2. Q: Where is your factory located? How can I visit there?

-----A: Our factory is located in Chengdu, Sichuan Province, China,

1) You can fly to Chengdu Airport directly. We will pick you up

when you arrive in the airport;

All our clients, from domestic or abroad, are warmly welcome to

visit us!

3.Q: What makes you different with others?

----A: 1) Our Excellent Service

For a quick, no hassle quote just send email to us

We promise to reply with a price within 24 hours - sometimes even

within the hour.

2) Our quick manufacturing time

For Normal orders, we will promise to produce within 30 working

days.

As a manufacturer, we can ensure the delivery time according to the

formal contract.

4.Q: How about the delivery time?

----A: This depends on the product. Typically standard products are

delivered within 45 days.

5. Q: What is the term of payment?

----A: 1) T/T payment; 2) L/C;

6.Q: May I know the status of my order?

----A: Yes .We will send you information and photos at different

production stage of your order. You will get the latest information

in time.

8. Products photos