Joiner Machinery Co., Ltd. |

|

Verified Suppliers

|

|

Special designed Buss Twin Screw Shaft Plastic Extruder elements for Continuous mixing

| Screw Design | Double-Screw |  |

| Hardness | 58-60HRC | |

| Brand Name | Jioner | |

| Surface Treatment | Sand blasting | |

| Materials | 6542/1.2379/WR2/WR5/WR14 etc. | |

| Place of Origin | Sichuan, China | |

| Warranty | 6 months | |

| Screw Range | Φ 15.6 - Φ 260mm | |

Spline | Involute inner spline | |

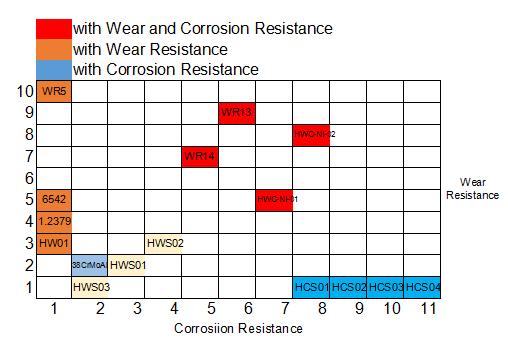

2. Screw Elements Materials:

1). For wear application:

Tool Steel : W6Mo5Cr4V2;

PM-HIP material : SAM10 SAM26 SAM39 CPM10V CPM9V

2). For corrision application:

Nitrided Steel: 38CrMoAI;

PM-HIP material : SAM26 SAM39 CPM10V CPM9V

3). For wear and corrision application:

PM-HIP material:SAM26 SAM39 CPM10V CPM9V

4). Other Materials:

Stainless Steel: 316L, C276 etc.

3. Making process

4. Heat treatment

heat treatment is very important in the screw production process. In order to ensure the quality of products, Joiner has purchased professional heat treatment equipment to produce, so that we can control the construction process by ourselves. In China, we are the only company that does heat treatment by ourselves, and the heat treatment of screw components made by Nanjing factory is processed by outsiders, so the quality of products can not be completely guarantee.

5. Why choose us?

1). Total solution of highly wear-resistance and

corrosion-resistance problems;

2). Expert of engineering design and consulting,

3). Advanced manufacturing capabilities and technology,

4). Lean production management

5). Top quality products with high cost performance

6. Packing Details:

According to your order quantities and products sizes to choose wooden boxes or cartons to pack:

7. Testing Reports for Our customer

We will send Inspection reports for every our customer.

1).General Dimension Inspection Report

2). Material certificate for customer.

Contact Information

Ms Jessica Zhang

Email:86 18380438354

What'sup: +86 18380438354

Mail: jessica.zhang@jiangningjx.com