Shenzhen Yideyi Technology Limited Company |

|

Rogers 100% ICT Testing CB Soldering Service Gerber Drawings

PCB Fabrication:

Offers One-Stop Solution for PCB & Prototype Assembly,

specializes in PCB Prototype and small series services. providing

high-tech low-cost PCB / multilayer boards with up to 14 layers.For

example Impedance Control PCB, Buried & Blind Holes PCB,

multilayer-layer PCBs.

PCB capability:

| Specification | |

| Numbr of Layer | 1-18Layers |

| Material | FR-4,FR2.Taconic,Rogers, CEM-1 CEM-3,ceramic , crockery Metal-backed Laminate |

| Surface Finish | HASL(LF), Gold plating, Electroless nickel immersion gold, Immersion Tin, OSP(Entek) |

| Finish Board Thickness | 0.2mm-6.00 mm(8mil-126mil) |

| Copper Thickness | 1/2 oz min;12 oz max |

| Solder Mask | Green/Black/White/Red/Blue/Yellow |

| Min.Trace Width & Line Spacing | 0.075mm/0.1mm(3mil/4mil) |

| Min.Hole Diameter for CNC Driling | 0.1mm(4mil) |

| Min.Hole Diameter for punching | 0.9mm(35mil) |

| Biggest panel size | 610mm*508mm |

| Hole Positon | +/-0.075mm(3mil) CNC Driling |

| Conductor Width(W) | 0.05mm(2mil)or; +/-20% of original artwork |

| Hole Diameter(H) | PTH L:+/-0.075mm(3mil); Non-PTH L:+/-0.05mm(2mil) |

| Outline Tolerance | 0.125mm(5mil) CNC Routing; +/-0.15mm(6mil) by Punching |

| Warp & Twist | 0.70% |

| Insulation Resistance | 10Kohm-20Mohm |

| Conductivity | <50ohm |

| Test Voltage | 10-300V |

| Panel Size | 110×100mm(min);660×600mm(max) |

| Layer-layer misregistration | 4 layers:0.15mm(6mil)max; 6 layers:0.25mm(10mil)max |

| Min.spacing between hole edge to circuity pqttern of an inner layer | 0.25mm(10mil) |

| Min.spacing between board oulineto circuitry pattern of an inner layer | 0.25mm(10mil) |

| Board thickness tolerance | 4 layers:+/-0.13mm(5mil); 6 layers:+/-0.15mm(6mil) |

Capability - SMT:

Lines:(5 Yamaha,4KME)

Capacity: 52 million placements per month

Max Board Size: 457*356mm.(18”X14”)

Min Component size: 0201-54 sq.mm.(0.084 sq.inch),long

connector,CSP,BGA,QFP

Speed: 0.15 sec/chip,0.7 sec/QFP

Capability - PTH:

Lines 2

Max board width 400 mm

Type Dual wave

Pbs status Lead-free line support

Max temp 399 degree C

Spray flux add-on

Pre-heat 3

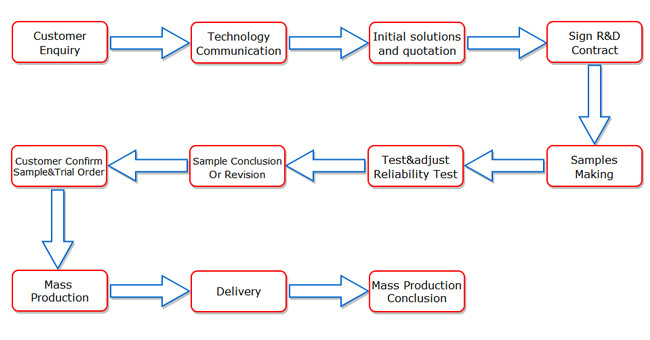

How to start order:

Shenzhen Yideyi Technology Co., Ltd in Shenzhen,China, which is the largest center of technology and electronics manufacturing in the world. Cooperating with our engineering team, quality team, these allow us to offer our customers low-cost, One-stop PCB Services.

FAQ:

Q1. How can we ensure our information should not let third party to

see our design?

We are willing to sign NDA effect by customer side local law and

promising to keep customers date in high confidential level in all

projects.

Q2. What service do you have?

We provide turnkey solution including RD, PCB fabrication, SMT,

final assembly,testing and other value-added service.

Q3. Please note that the following detail will speed up evaluation:

Material:

Board thickness:

Copper thickness:Surface finish:

Solder mask color:

Silkscreen color:

Q4. How about the delivery?

Normally, for sample order, our delivery is about 5 days.For small

batch, our delivery is about 7 days.

For mass production batch, our delivery is about 10 days.

But that depends on the real condition when we get your order.

If your order is urgently please contact us directly ,we will

priority to deal it and do ourbest to give you satisfied delivery

time.

Q5. With payment terms do we accept?

For sample order or small batch, we suggest you to use Pay-pal and

Western Union.For mass production batch, we suggest you to use T/T.

Q6. How can we guarantee you receive an good quality product?

For PCB, we will use Flying Probe Test, E-test etc. for it.

For PCBA, we need you to offer us a method or test fixture for the

function test.Before that, our inspectors will use microscope and

X-ray to check the IC footwelding or bad solder etc.

Q7. What are the main products of your PCB/PCBA service?

Automotive, medical, Industrial control, Internet of Things, Smart home, military, Aerospace.