Zhuzhou Mingri Cemented Carbide Co., Ltd. |

|

Verified Suppliers

|

|

G50 long lifetime cemented carbide dies for punching stamping cold

heading molds

Description:

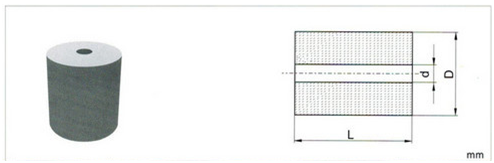

Size outer diamter: ∅2-∅380mm

inside diameter: φ1-∅360mm

length: 1-200mm

The whole die set must be able to withstand the radial pressure during the operations to hold the tolerances in the horizontal cross-section of the component to be formed .

The die (carbide die inserts and punches ) experiences impact and sliding wear and quite often sees abrasive wear patterns during progressive stamping ,especially on thicker components ,It also sees adhesive wear through friction because of the metal-metal motion of the top punch sections when leaving the ides

Therefore,tools should effectively resist wear ,corrosion,galling and impact .So we create our new grade for tungsten carbide dies .,it will increase 2-9 times of the lifetime of molds with superior corrosion resistance ,superior toughness and anti-galling characteristics

Bolts&nibs,Nut forming dies,non standard dies

Characteristics:

Homogeneous property,good wear resistance ,high impact resistance

Application :

Mould and die industry ,such as cold heading dies,powder metallurgy

dies and all kinds of hardware forging dies,etc

Company information

Located in zhuzhou city,hunan province--the gungsten carbide base

of China,zhuzhou mingri cemented carbide co. ltd .was established

in May,2001 with the investment of 10 million dollars area of 33300

㎡.With up-to-date production line ,advanced equipments,professional

technicians and experts with national awards as the full time

consultants,we have obtained 35 patents in invention,utility model

and design,We have also passed ISO9001:2015 Certification in

quality and ISO9001:14001 Certification in environment ,In recent

years ,our capacity,quality and service have beeen further greatly

improved due to plant expansion,introducion of advanced

technologies and equipments at home and abroad and applicaition of

6S management.

Applications:

1, tungsten carbide die use puching and stamping machine parts

2, tungsten carbide die use for drawing steel tubes and rods

3, tungsten carbide die ues for impact-resistant forging die, hot

forging die and finished rollers

4, also use for nut wear resistant or impact resistant dies

5, use for nut forming die and high impact-resistant die

6, use for punching dies

Our Advantages:

1. Retain size within required tolerance

2. Galling resistance improves surface finish

3. Minimizes breakage and extends wear life

4. Provides an advantage in reduced manufacturing costs

Grade:

How do we recommend or create a grade for a specific application such as stamping ?

| Grade | Density g/cm3 | T.R.S MPα | Hardness HRA | Properties & Applications | Approx Grades in China |

| YM20 | 13.5 | 2800 | 85.5 | It is suitable for manufacturing punching dies for watch parts, leaf spring of musical instruments, battery jars, small sized steel balls, screws, screw caps, etc. | YG20 |

| ML32 | 13.9 | 2750 | 85.5 | It is suitable for impact-resistantance forging dies. | YG16C |

| ML36 | 13.7 | 2800 | 84.5 | It is suitable for impact-resistant forging dies, hot-forging dies and finishing rollers. | YG18C |

| ML40 | 13.5 | 2850 | 83.5 | It is suitable for wear resistant or impact resistant dies. | YG20C ZL40.2 |

| ML50 | 13.3 | 2900 | 83.0 | It is suitable for nut forming dies and high impact-resistantance dies. | YG22C ZL40.5 |

| ML60 | 13.1 | 2950 | 82.5 | It is suitable for stainless screw dies and semifinishing rollers. | YG25C ZL40B |

| ML100 | 13.1 | 3050 | 83.4 | It is suitable for screw cap forming dies with high strength ( highest impact-resistant forging dies). | YG25C GT55 |

| Other grades of cemented carbide blanks for cold-forging dies may be offered by customers' requirements | |||||

Specifications:

Including but not limited to the following types.

Why choose us?

1. Zhuzhou Mingri has the richest molds stock of all kinds of

cold and hot punching dies.

2. With stable relationship with our customers.

3. The most advanced tooling warehouse.

4. The largest production capacity and fastest delivery .

5. The most reliable testing machines for all specifications.

6. The best and reliable after service.

Feel free to contact me if any needs:

Whatsapp/wechat/phone:008618593402651

Facebook:Xiao Aimee

zhuzhou mingri cemented carbide co. ltd

Email:mr009@mrcarbide.com