Zhuzhou Gingte Cemented Carbide Co.,LTD |

|

Tungsten Steel Dies Cold Heading Dies and Cold Forming Dies for Fasteners Industry

Product Quick Detail :

1. Product Name: Tungsten Steel Dies Cold Heading Dies

2. Material: Tungsten Steel

3. Size: various carbide die sizes or as customer's request

4. Size Tolerance: free tolerance or as customer's request

5. Shape: Round Shape with hole

6. Recommend Grade: YG20C YG25C etc

7. Grain Size: Coarse Grain

8. Sintering: HIP sintering

9. Surface Treatment: Finished

10. Product Features: high strength, long life

11. Certification: ISO9001

Product Advantages:

We specialize in making the highest quality custom carbide

dies, quickly and at the best value in the industry. We understand

that our customer’s time is money, so we take care of them from

start to finish. With our approach you don't just get the lowest

cost on precision carbide dies, we also protect you from the hidden

costs that come with less than amazing customer service.

Gingte has over 10 years experience in creating high quality

carbide dies, in fact, precision carbide dies are our specialty.

With Gingte, you can expect superior dies to be delivered when you

need them. Perhaps most importantly, We put our customers

first and will be happy to work with you to make sure you get

the dies you need, when you need them. If you need anything from an

expert opinion about your processes to rush delivery, we will be

there for you.

Why Choose Us ?

1. Proffessional tungsten carbide manufacturer over 10 years.

2. Located in zhuzhou, A well-known hub for the production of cemented carbide,We have easy access to a wealth of raw materials.

3. Annual production capacity over 400tons.

4. More than 10000 sets of exisiting non-standard molds,fast delivery!

5. Top R&D team and 12-member QC team that follows a five-point inspection routine,covering raw material,production processes, semi-finished products, finished products and packaged goods.

6. ISO9001:2008 Quality Management System.

Various Grades for Options:

| Tungsten Carbide Cold Forging/heading Dies | |||||

| Grades | Density | T.R.S | Hardness | Performance & application recommended | |

| g/cm³ | MPa | HRA | |||

| YG11 | 14.4 | ≥3000 | 88.5 | Forming or stamping dies for metal powders and nonmetal powders. | |

| YG15 | 14 | ≥3400 | 87.5 | For fabricating drawing dies of steel tubes and rods under High compressibility ratio; punching, stamping, forging tools under large stress. | |

| YG20 | 13.5 | ≥3800 | 85.5 | For fabricating of stamping dies for watch parts, spring plates of musical instruments, battery jars, small sized steel balls, screws, screw caps. | |

| YG15C | 14 | ≥4000 | 86.5 | For oil cone drill bits,cut medium soft and hard rocks;debarking and cutting of frozen wood,soft wood and original wood. | |

| YG16C | 13.9 | ≥3500 | 85.5 | Impact resistance forging dies. | |

| YG18C | 13.7 | ≥3600 | 84.5 | Impact resistance forging dies, hot-press forging dies and rollers. | |

| YG20C | 13.5 | ≥3800 | 83.5 | Dies for wear resistant or impact resistant application. | |

| YG22C | 13.3 | ≥4000 | 83 | Nut forming dies and high impact resistance forging dies. | |

| YG25C | 13.1 | ≥4250 | 82.5 | Stainless bolt header dies and rollers. | |

Various Sizes for Options:

Type | OD | ID | H | Tolerance | ||

OD | Id | H | ||||

φD10~14×φd | 10~14 | 1.0~5.0 | 15~40 | D×+3% | d×-3% | H×+3% |

φD15~24×φd | 15~24 | 1.5~8.0 | 20~60 | |||

φD25~40×φd | 25~40 | 1.5~25 | 30~60 | |||

φD42~95×φd | 42~95 | 2.0~50 | 20~95 | |||

For any other sizes we are able to custom-made according to clients’ requirements or drawings.

Product Display:

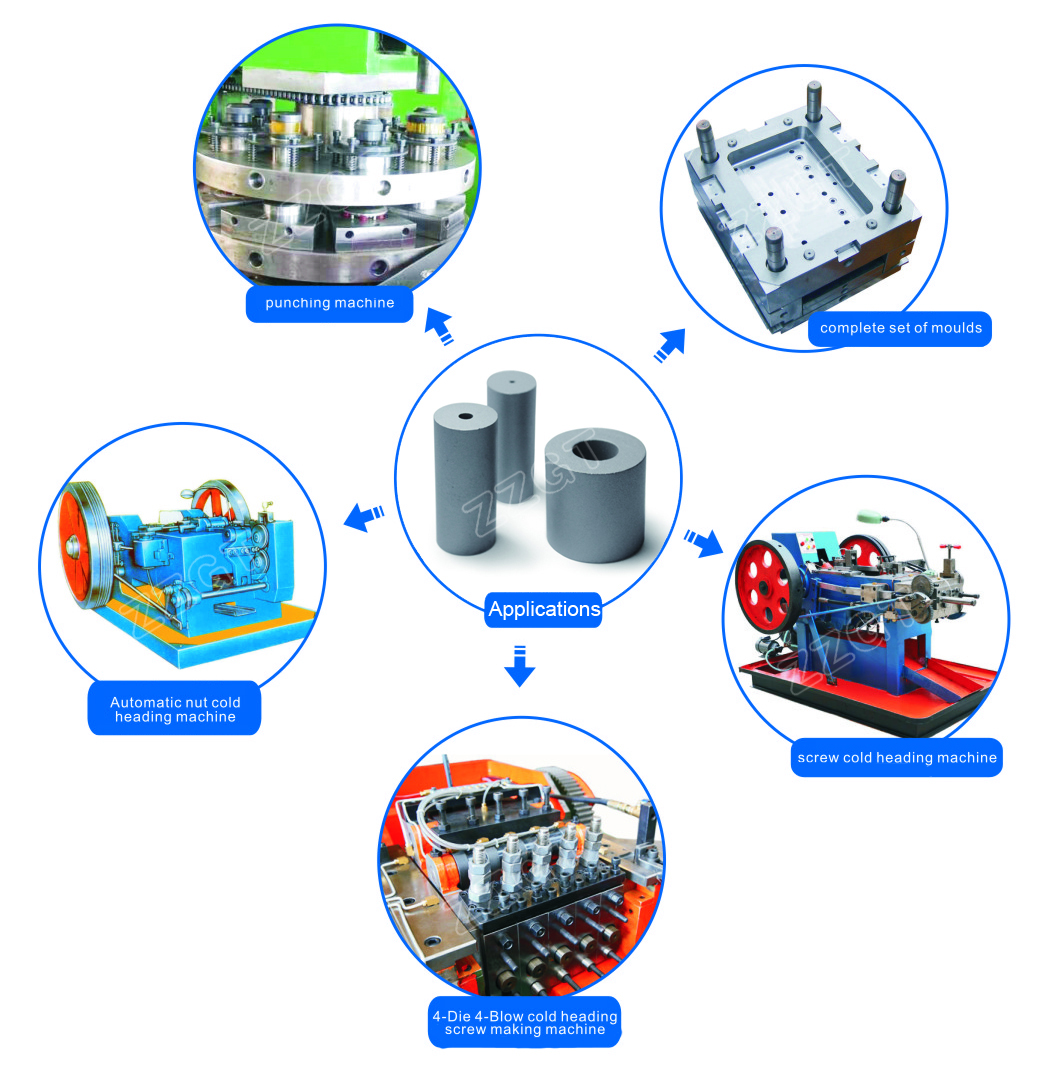

Applications:

Quality assurance:

Every production process has a special person to test to ensure quality

Have professional engineers to check the quality

All products are under strict quality system management based on ISO9001:2008

Packing Process:

FAQ

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How can i place an order ?

A: Please provide the details of your requirements as clear as

possible. So we can send you the offer at the first time.

For designing or further discussion, it is better to contact us

with Skype / email / phone, in case of any delays.

Q: What is your terms of delivery ?

A: We accept EXW, FOB, C&F, CIF, DDU, DDP, etc. You can choose

the one which is the most convenient or cost effective for you.

Q: How long is your delivery time ?

A: Generally it is 3-5 days if the goods are in stock. or it is 15-25 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 30% T/T in advance ,balance before shippment.

Contact us at your free time when you are interested in our products : )