Zigong Xingyu Cemented Carbide Dies & Tools Co., Ltd. |

|

Wholesale Tungsten Carbide Mechanical Valve Seat With Good Customized Service

Description of valve ball and vale seat for sucker rod pumps in oil field

1. Valve balls and valve seats are widely used in oil fields.

2. Valve Ball and Seat performance directly affects the use effect

and service life of the sucker rod pumps.

3. Each ball-and-seat combination is vacuum tested to ensure a

perfect seal is obtained in all positions of contact.

Details

1. Commended quality grade : YG6,YG6X,YG8,YG15

2. Property: High hardness,good wear resistance,good corrosion resistance,good bend resistance,and tungsten carbide balls has excellent performance in complicated and poor machinery working conditions. hardness: HRA90.5,denstiy≥14.8g/cm3.

3. Classification:Tungsten carbide is powder metallurgy

item,including unground blank carbide balls,well ground

carbide balls,carbide punching ball,carbide bearing ball,carbide

valve ball,non-magnetic carbide ball,carbide measuring ball and

carbide pen balls.

4. Application: Tungsten carbide ball was widely used in precision tools drawing and punching,high precision bearings,high precision measuring instrument and gages,water pump and brake pump,and various machinery sealing accessories part in high-tech industry.

Grade List

| Grade | ISO Code | Chemical Composition(%) | Physical Mechanical Properties (≥) | Application | ||||

| WC | Co | Density g/cm3 | Hardness(HRA) | T.R.S N/mm2 | ||||

| YG3 | K01 | 97 | 3 | 14.90 | 91.00 | 1180 | Suitable for finishing of cast iron,non-ferrous metals,alloys and non-metallic materials,and semi-finishing vehicles for intermittent cutting. | |

| YG6 | K10 | 94 | 6 | 15.10 | 92.00 | 1420 | Finishing of chilled hard alloy cast iron and heat resistant alloy steel and ordinary cast iron. | |

| YG6X | K20 | 94 | 6 | 15.10 | 91.00 | 1600 | Cast iron, non-ferrous metals and alloys, non-metallic materials, medium to cutting, semi-finishing and finishing. | |

| YG8 | K20-K30 | 92 | 8 | 14.90 | 90.00 | 1600 | Suitable for casting of cast iron, non-ferrous metals and their alloys and non-metallic materials, roughing of sections and rough cutting. | |

| YG10 | K40 | 90 | 10 | 14.70 | 89.00 | 1900 | Suitable for the production of drawing dies, wear parts and stamping parts and cores for hard alloy automatic presses. | |

| YG10X | K40 | 89 | 10 | 14.70 | 89.50 | 2200 | Suitable for small diameter micro drills, end mills, rotary boring tools, etc. | |

| YG15 | K30 | 85 | 15 | 14.70 | 87.00 | 2100 | Forging, perforating and stamping tools for steel bars and steel tubes with high compression ratios and working under large stresses. | |

| YG20 | K30 | 80 | 20 | 13.70 | 85.50 | 2500 | Stamping die, stamping watch parts, musical instrument spring piece. | |

| YG20C | K40 | 80 | 20 | 13.70 | 82.00 | 2200 | punching battery case, toothpaste skin mold, small size steel ball, screw, nut stamping die, hot rolling twist drill bit plate. | |

| YG30 | G60 | 70 | 30 | 12.80 | 82.00 | 2750 | Production of standard parts, bearings, tools and other industries for cold heading, cold punching, cold pressing die. | |

Grade and applicaton for valve seat

| Grade | Co (wt%) | Density (g/cm³) | Hardness(HRA) | TRS (≥N/mm²) | Application |

| XC100 | 5.8-6.2 | 14.6-15.0 | 91.5-92.5 | 2000 | Wear-resistant |

| XC101 | 5.8-6.2 | 14.6-15.0 | 91.5-92.5 | 2500 | |

| XC200 | 7.8-8.2 | 14.5-14.9 | 91.0-92.0 | 2100 | |

| XC201 | 7.8-8.2 | 13.5-14.9 | 91.0-92.0 | 2800 | |

| XC300 | 9.8-10.3 | 14.2-14.6 | 90.5-91.5 | 2600 | |

| XC301 | 9.8-10.3 | 14.2-14.6 | 90.5-91.5 | 3200 | |

| Grade | Ni (wt%) | Density (g/cm³) | Hardness (HRA) | TRS (≥N/mm²) | Application |

| XN100 | 6.5-7.5 | 14.5-14.8 | 88.5-91.0 | 1800 | Corrosion-resistant |

| XN101 | 6.5-7.5 | 14.5-14.8 | 88.5-91.0 | 2200 | |

| XN300 | 10.0-11.0 | 14.2-14.6 | 86.5-89.5 | 2100 | |

| XN301 | 10.0-11.0 | 14.2-14.6 | 86.5-89.5 | 2400 |

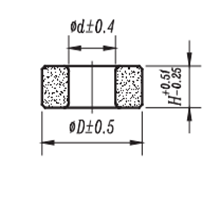

| Seats dimension (mm) | ||

| D | d | H |

| 19.48 | 11.68 | 12.7 |

| 22.66 | 13.97 | 12.7 |

| 28.22 | 17.02 | 12.7 |

| 33.81 | 20.96 | 12.7 |

| 36.09 | 24.38 | 12.7 |

| 41.43 | 26.92 | 12.7 |

| 48.79 | 33.27 | 12.7 |

| 74.93 | 43.18 | 19.05 |

| Ball dimension (mm) | ||

| D±1.27(mm) | ||

| 15.88 | ||

| 19.05 | ||

| 23.83 | ||

| 28.58 | ||

| 31.75 | ||

| 34.93 | ||

| 42.88 | ||

| 57.15 |

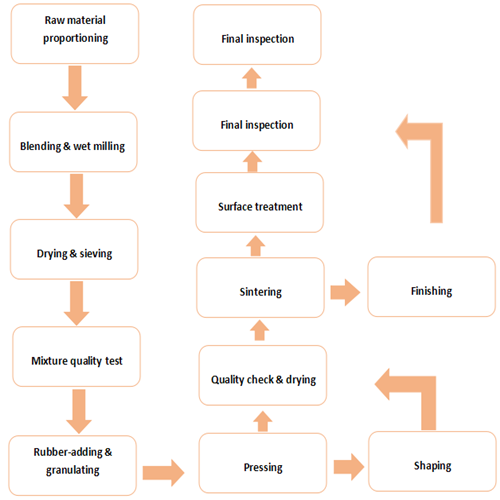

Production Process

FAQ

Q1: Are you trading company or manufacturer ?

A1: We are Factory with 20 years of production experience.

Q2: Where is your factory?

A2: We are located in Zigong city, Sichuan province where is3 hours away from Chengdu by Car.

Q3: Is the competitive price of tungsten carbide parabolic buttons?

A3: We have our own Factory. Due to strong production and distribution system, we promise to offer our customers the most competitive price.

Q4: Is the top quality?

A4: Yes. All products will be tested before bulk processing, and we

will check the physi-cal properties, shape and

tolerance for ensuring qualified products before shipping.

Q5: What’s your delivery time ?

A5: For the normal type which we have mold it takes 10-15 days

after receiving the advance payment.

For the non standard which we do not have mold it takes 15-25 days

after receiving the advance payment.

Q6: Do you provide samples ? is it free or extra ?

A6: Yes, we could offer the sample (less than 1Kg) for free charge without freight charge.