Zigong Xingyu Cemented Carbide Dies & Tools Co., Ltd. |

|

Customized High Precision Cemented Carbide Valve Seat For Petrochemical Industry

Application

Tungsten carbide also called tungsten cemented carbide, cemented carbide or simply carbide.Tungsten carbide (WC) is an inorganic chemical compound containing equal parts of tungsten and carbon atoms. Tungsten cemented carbide can be pressed and formed into shapes from fine

gray powder, which is considered to be its most basic form.Tungsten cemented carbide plate is approximately three times stiffer than steel, with a Young's modulus of approximately 550 GPa, and is much denser than steel or titanium. It is comparable with corundum or sapphire in hardness and can only be polished and finished with abrasives of superior hardness such as cubic boron nitride and diamond among others, in the form of powder, wheels, and compounds.

Tungsten cemented carbide is the preferred material for parts that

must withstand all forms of wear (including sliding abrasion,

erosion, corrosion/wear and metal-to-metal galling) and exhibit a

high degree of toughness. It exhibits high compressive strength,

resists deflection, and retains its hardness values at high

temperatures, a physical property especially useful in

metal-cutting applications.

We have got ISO9001-2018 quality certificate and top good quality

products could be provided to you. Our Company is a leading

professional manufacturer in this field for more than 20 years.We

produce both standard and non-standard products. Special

Drawings/requirements can be accepted good quality, reasonable

price and good service are guaranteed.If you have any interest in

our products, please kindly send us your enquiry to us.

Grade List

| Grade | ISO Code | Chemical Composition(%) | Physical Mechanical Properties (≥) | Application | ||||

| WC | Co | Density g/cm3 | Hardness(HRA) | T.R.S N/mm2 | ||||

| YG3 | K01 | 97 | 3 | 14.90 | 91.00 | 1180 | Suitable for finishing of cast iron,non-ferrous metals,alloys and non-metallic materials,and semi-finishing vehicles for intermittent cutting. | |

| YG6 | K10 | 94 | 6 | 15.10 | 92.00 | 1420 | Finishing of chilled hard alloy cast iron and heat resistant alloy steel and ordinary cast iron. | |

| YG6X | K20 | 94 | 6 | 15.10 | 91.00 | 1600 | Cast iron, non-ferrous metals and alloys, non-metallic materials, medium to cutting, semi-finishing and finishing. | |

| YG8 | K20-K30 | 92 | 8 | 14.90 | 90.00 | 1600 | Suitable for casting of cast iron, non-ferrous metals and their alloys and non-metallic materials, roughing of sections and rough cutting. | |

| YG10 | K40 | 90 | 10 | 14.70 | 89.00 | 1900 | Suitable for the production of drawing dies, wear parts and stamping parts and cores for hard alloy automatic presses. | |

| YG10X | K40 | 89 | 10 | 14.70 | 89.50 | 2200 | Suitable for small diameter micro drills, end mills, rotary boring tools, etc. | |

| YG15 | K30 | 85 | 15 | 14.70 | 87.00 | 2100 | Forging, perforating and stamping tools for steel bars and steel tubes with high compression ratios and working under large stresses. | |

| YG20 | K30 | 80 | 20 | 13.70 | 85.50 | 2500 | Stamping die, stamping watch parts, musical instrument spring piece. | |

| YG20C | K40 | 80 | 20 | 13.70 | 82.00 | 2200 | punching battery case, toothpaste skin mold, small size steel ball, screw, nut stamping die, hot rolling twist drill bit plate. | |

| YG30 | G60 | 70 | 30 | 12.80 | 82.00 | 2750 | Production of standard parts, bearings, tools and other industries for cold heading, cold punching, cold pressing die. | |

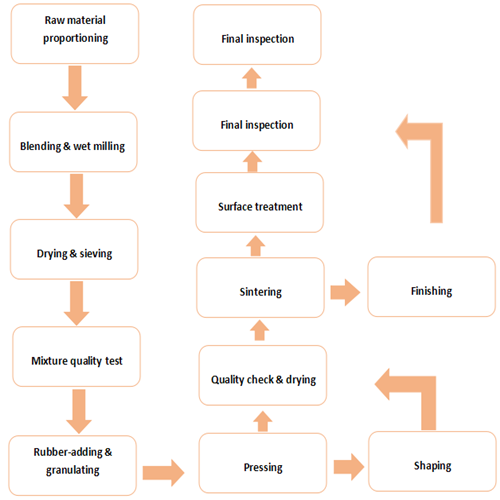

Production Process

Factory Advantage

1. we choose 100% raw material .

2. You can choose many kinds of grades for your need.

3. we have professional advanced production and testing equipments ensure high quality products.

4. Precision Ground and polished

5. High wear resistance,high hardness and impact toughness

6. Advanced technology , precision grinding.