Zigong Xingyu Cemented Carbide Dies & Tools Co., Ltd. |

|

Wear Resistant Parts Drill Bit Inserts Cemented Tungsten Carbide Dome Buttons

Application

Tungsten carbide button has its unique performance, so is widely

used in oil drilling, and shoveling snow, snow plow machines and

other equipment.Also used to drill for coal, mining tools and road

sweeping and snow removal and road maintenance tools. In a

quarry,Mining and tunneling using tools, as well as residential

buildings.

Cemented carbide spherical gear with excellent wear resistance and toughness, and similar products is higher than the drilling speed. Ball tooth series bit passive use of long cycle, its life is about the same diameter blade grinding head bit 5-6 times the wear life, conducive to saving auxiliary working hours, reduce the speed of work and speed up construction workers.

Grade List

| Grade | Co% | Density (g/cm2) | Hardness (HRA/HV30) | TRS (N/mm2) | Application |

| XD05 | 5.5 | 14.9-15.1 | 1380-1500 | ≥2800 | High hardness and wear resistance, suitable for making various parabolic buttons. |

| XK05 | 6.0 | 14.82-14.98 | 1370-1490 | ≥2300 | Suitable for making various sizes of buttons with fine resistance to impact and wear for drilling soft and medium hard formations at a higher speed rate. |

| XD10 | 6.2 | 14.80-15.00 | 1320-1470 | ≥2000 | High toughness, suitable for making buttons for high air pressure DTH bits drilling medium hard and hard rock formations. |

| XD10B | 6.5 | 14.75-14.95 | 1300-1460 | ≥2300 | Mainly for making buttons for low air pressure bits in mining. |

| XD20C | 7.0 | 14.7-14.9 | 1320-1450 | ≥2500 | With more cobalt content and toughness than that of grade YK05, it is a tougher alternative to grade YK05 to avoid risk of breakage of bits at high speed drilling rate. |

| XK10.5 | 7.5 | 14.7-14.85 | 89.0-90.5 | ≥2600 | Mainly for making buttons for DTH bits in various sizes of conical, parabolic and spherical buttons. |

| XK10 | 8.0 | 14.6-14.76 | 1200-1320 | ≥2340 | Mainly for making buttons of medium and small sizes for bits drilling soft and medium hard rock formations, also for making inserts for other drill bits. |

| YG8C | 8.3 | 14.55-14.75 | ≥87.5 | ≥2000 | Mainly for making buttons of medium & small sizes for drilling soft and medium hard rock formations. |

| Shape &Code | Picture | Drawing | Size | ||

| D(mm) | H(mm) | h(mm) | |||

| Ballistic compact |  |  | 7.4-29.7 | 10.0-32.0 | 3.7-13.0 |

| Spherical compact |  |  | 4.4-28.6 | 6.0-38.0 | |

| Conical compact |  |  | 5.4-25.4 | 7.0-42.0 | |

| scoop compact |  |  | 8.3-32.6 | 13.0-52.0 | 4.7-22.5 |

| Ballistic Wedge compact |  |  | 8.0-30.5 | 10.0-40.0 | 3.5-16.3 |

| Ballistic Wedge compact |  |  | 18.4-25.4 | 30.0-42.0 | 11.7-18.0 |

| aerofoil compact |  |  | 10.0-22.8 | 15.0-35.0 | 4.8-9.2 |

| special head preform |  |  | 11.15-12.84 | 13.7-16.2 | 8.5-10.4 |

| special head preform |  |  | 11.15-14.35 | 13.5-10.7 | 7.5-19.7 |

| special head preform |  |  | 10.2 | 14.6 | 9.4 |

| special head preform |  |  | 18.0-24.0 | 10.0-35.0 | 22.0-30.0 |

Details For Spherical Rock Drill Bits

| Type | Dimensions (mm) | Angles | |||

| D | H | SR | α° | βº | |

| Q0809 | 8.25 | 9 | 4.4 | 20 | 26.5 |

| Q0812 | 8.25 | 12.3 | 4.4 | 20 | 26.5 |

| Q0813 | 8.25 | 13.3 | 4.4 | 20 | 26.5 |

| Q0913 | 9.25 | 13.5 | 5 | 20 | 26.5 |

| Q0914 | 9.25 | 14 | 5 | 20 | 26.5 |

| Q0915 | 9.25 | 15 | 5 | 20 | 26.5 |

| Q1014 | 10.25 | 14 | 5.5 | 20 | 26.5 |

| Q1015 | 10.25 | 15 | 5.5 | 20 | 26.5 |

| Q1016 | 10.25 | 16.3 | 5.5 | 20 | 26.5 |

| Q1017 | 10.25 | 17.3 | 5.5 | 20 | 26.5 |

| Q1019 | 10.25 | 19 | 5.5 | 20 | 26.5 |

| Q1116 | 11.3 | 16 | 6 | 20 | 26.5 |

| Q1117 | 11.3 | 17 | 6 | 20 | 26.5 |

| Q1119 | 11.3 | 19 | 6 | 20 | 26.5 |

| Q1217 | 12.35 | 17.1 | 6.6 | 20 | 26.5 |

| Q1218 | 12.35 | 18 | 6.6 | 20 | 26.5 |

| Q1219 | 12.35 | 19 | 6.6 | 20 | 26.5 |

| Q1222 | 12.35 | 22.2 | 6.6 | 20 | 26.5 |

| Q1318 | 13.35 | 18 | 7 | 20 | 26.5 |

| Q1320 | 13.35 | 20 | 7 | 20 | 26.5 |

| Q1322 | 13.35 | 22 | 7 | 20 | 26.5 |

| Q1420 | 14.35 | 20 | 7.7 | 20 | 14.5 |

| Q1422 | 14.35 | 22.2 | 7.7 | 20 | 14.5 |

| Q1423 | 14.35 | 23 | 7.7 | 20 | 14.5 |

| Q1622 | 16.35 | 22 | 8.8 | 20 | 14.5 |

| Q1624 | 16.35 | 24 | 8.8 | 20 | 14.5 |

| Q1625 | 16.35 | 25 | 8.8 | 20 | 14.5 |

Product Application Scene

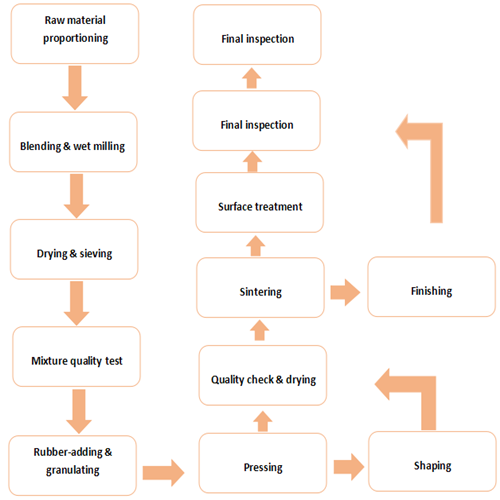

Production Process

FAQ

A1: What is your main product?

Q1: The main product include tungsten carbide bar, carbide wire

drawing die, carbide punching dies, carbide drill bit button,

carbide

bushings, carbide strip and carbide plate, and any other carbide products and customized products.

A2: Do you have certification on your products?

Q2: ISO 9001:2015

A3: What is about your general delivery date?

Q3: Nomally 7-15 workdays .

A4: What is your packing?

Q4: We use standard export packing and customized is available.

A5: Can I get the samples?

Q5: Sure, contact us directly.