Zigong Xingyu Cemented Carbide Dies & Tools Co., Ltd. |

|

Raw Pure Material K10 Tungsten Carbide Strips/ K10 Cemented Carbide Strips

Introduction

Usage: used for sand making machine to crush hard granite,marble , grave, etc.This kind of strips need to be higher wear resistance and high thoughness.We have special researches in the material for crushing stones,so our engineer will recommend you the most suitable material grade for you based on your working application.

The main using purpose of Tungsten Carbide Strips is to make

cutting tools for woodworking, like forming tools and different

kinds of blades to cut Nature wood, HDF, MDF, Ply wood, Particle

board and some non-metal material.

It is very important to select the right grade to match the using

purpose, we have to consider the physical properties of the

processing object, also the working condition for tools, like

running speed, impact.

We provide a wide range of squared and flat Carbide Strips in different dimensions, minimum 1.0 mm thickness. Also, we have rich experience for making customized strips, like the strips with single cutting angle, double cutting angles, strips with cutting angles and also holes.

Features

1: 100% virgin raw material

2: High hardness ,excellent wear-resistance

3: High elastic modulus and compressive strength

4: Stable chemical properties

5: Blanks,precision grinded and polished

6: Various sizes and grades

7: Factory' offer

8: Strict products quality inspection

9: OEM and ODM are accepted

Details of tungsten carbide plate

| Grade | YG6A | YG8 | YG15 | YG20 | YS2T | |

| ISO Code | K10 | K20 | K30-40 | K05 | K10-K20 | |

| Co | % | 6 | 8 | 15 | 20 | 15 |

| Wc | % | 94 | 92 | 85 | 80 | 85 |

| Density | G/cm3 | 14.9 | 14.7 | 14.5 | 13.5 | 14.5 |

| T.R.S | Mpa | 1850 | 2400 | 2500 | 2800 | 2350 |

| Hardness | HRA | 92 | 89.5 | 87.5 | 85.5 | 92 |

Grade List

| Grade | ISO Code | Chemical Composition(%) | Physical Mechanical Properties (≥) | Application | ||||

| WC | Co | Density g/cm3 | Hardness(HRA) | T.R.S N/mm2 | ||||

| YG3 | K01 | 97 | 3 | 14.90 | 91.00 | 1180 | Suitable for finishing of cast iron,non-ferrous metals,alloys and non-metallic materials,and semi-finishing vehicles for intermittent cutting. | |

| YG6 | K10 | 94 | 6 | 15.10 | 92.00 | 1420 | Finishing of chilled hard alloy cast iron and heat resistant alloy steel and ordinary cast iron. | |

| YG6X | K20 | 94 | 6 | 15.10 | 91.00 | 1600 | Cast iron, non-ferrous metals and alloys, non-metallic materials, medium to cutting, semi-finishing and finishing. | |

| YG8 | K20-K30 | 92 | 8 | 14.90 | 90.00 | 1600 | Suitable for casting of cast iron, non-ferrous metals and their alloys and non-metallic materials, roughing of sections and rough cutting. | |

| YG10 | K40 | 90 | 10 | 14.70 | 89.00 | 1900 | Suitable for the production of drawing dies, wear parts and stamping parts and cores for hard alloy automatic presses. | |

| YG10X | K40 | 89 | 10 | 14.70 | 89.50 | 2200 | Suitable for small diameter micro drills, end mills, rotary boring tools, etc. | |

| YG15 | K30 | 85 | 15 | 14.70 | 87.00 | 2100 | Forging, perforating and stamping tools for steel bars and steel tubes with high compression ratios and working under large stresses. | |

| YG20 | K30 | 80 | 20 | 13.70 | 85.50 | 2500 | Stamping die, stamping watch parts, musical instrument spring piece. | |

| YG20C | K40 | 80 | 20 | 13.70 | 82.00 | 2200 | punching battery case, toothpaste skin mold, small size steel ball, screw, nut stamping die, hot rolling twist drill bit plate. | |

| YG30 | G60 | 70 | 30 | 12.80 | 82.00 | 2750 | Production of standard parts, bearings, tools and other industries for cold heading, cold punching, cold pressing die. | |

| ISO Code | Grain Size (μm) | Co (mass) % | TRS (GPa) *1 | Hardness | Application | Work Material | |||||||

| HRA *2 | HV *3 | For Automatic Lathes | Cemented Carbide Plates | General Steel | Stainless Steel | Cast Iron | Non-ferrous Metal | Heat Resistant Alloy | |||||

| Cemented Carbide | K20 | <0.9 | 10 | 2.5 | 91 | 1550 | √ | √ | O | ||||

| K10 | <1.0 | 6 | 2 | 92 | 1700 | √ | √ | O | O | ||||

| M20 | <3.0 | 9 | 2 | 90.5 | 1450 | √ | √ | O | O | ||||

| Cermet | P10 | <2.0 | 18 | 2 | 91.2 | 1500 | √ | O | |||||

| P20 | <2.0 | 19 | 2 | 90.5 | 1450 | √ | O | ||||||

Detail Specification For Tungsten Carbide Strips

| Type Number | Dimensions(mm) | |||||

| L | L | T | ||||

| 18*13*T | 18 | ±0.5 | 13 | ±0.4 | 2~8 | ﹢0.5 |

| 18*15*T | 18 | ±0.5 | 15 | ±0.4 | 2~8 | ﹢0.5 |

| 18*18*T | 18 | ±0.5 | 18 | ±0.4 | 2~12 | ﹢0.5 |

| 19*5*T | 19 | ±0.5 | 5 | ±0.3 | 2~8 | ﹢0.5 |

| 19*8*T | 19 | ±0.5 | 8 | ±0.3 | 2~8 | ﹢0.5 |

| 19*11*T | 19 | ±0.5 | 11 | ±0.4 | 2~8 | ﹢0.5 |

| 19*13*T | 19 | ±0.5 | 13 | ±0.4 | 2~8 | ﹢0.5 |

| 20*2*T | 20 | ±0.5 | 2 | ±0.3 | 2~4 | ﹢0.5 |

| 20*3*T | 20 | ±0.5 | 3 | ±0.3 | 2~5 | ﹢0.5 |

| 20*4*T | 20 | ±0.5 | 4 | ±0.3 | 2~7 | ﹢0.5 |

| 20**T | 20 | ±0.5 | 5 | ±0.3 | 2~8 | ﹢0.5 |

| 20*3*T | 20 | ±0.5 | 6 | ±0.3 | 2~8 | ﹢0.5 |

| 20*7*T | 20 | ±0.5 | 7 | ±0.3 | 2~8 | ﹢0.5 |

| 20*8*T | 20 | ±0.5 | 8 | ±0.3 | 2~7 | ﹢0.5 |

| 20*9*T | 20 | ±0.5 | 9 | ±0.3 | 2~8 | ﹢0.5 |

| 20*10*T | 20 | ±0.5 | 10 | ±0.3 | 2~8 | ﹢0.5 |

| 20*12*T | 20 | ±0.5 | 12 | ±0.4 | 2~8 | ﹢0.5 |

| 20*15*T | 20 | ±0.5 | 15 | ±0.4 | 2~12 | ﹢0.5 |

| 20*18*T | 20 | ±0.5 | 18 | ±0.4 | 2~12 | ﹢0.5 |

| 20*20*T | 20 | ±0.5 | 20 | ±0.4 | 2~12 | ﹢0.5 |

| 21*3*T | 21 | ±0.5 | 3 | ±0.3 | 2~7 | ﹢0.5 |

| 21*7*T | 21 | ±0.5 | 7 | ±0.3 | 2~7 | ﹢0.5 |

| 21*8*T | 21 | ±0.5 | 8 | ±0.3 | 2~8 | ﹢0.5 |

| 21*9*T | 21 | ±0.5 | 9 | ±0.3 | 2~8 | ﹢0.5 |

| 21*13*T | 21 | ±0.5 | 13 | ±0.4 | 2~7 | ﹢0.5 |

| 21*20*T | 21 | ±0.5 | 20 | ±0.4 | 2~12 | ﹢0.5 |

| 21*21*T | 21 | ±0.5 | 21 | ±0.4 | 2~12 | ﹢0.5 |

| 22*3*T | 22 | ±0.5 | 3 | ±0.3 | 2~6 | ﹢0.5 |

| 22*5*T | 22 | ±0.5 | 5 | ±0.3 | 2~8 | ﹢0.5 |

| 22*8*T | 22 | ±0.5 | 8 | ±0.3 | 2~8 | ﹢0.5 |

| 22*12*T | 22 | ±0.5 | 12 | ±0.4 | 2~8 | ﹢0.5 |

| 22*15*T | 22 | ±0.5 | 15 | ±0.4 | 2~8 | ﹢0.5 |

| 22*22*T | 22 | ±0.5 | 22 | ±0.4 | 2~26 | ﹢0.5 |

| 23*4*T | 23 | ±0.5 | 4 | ±0.3 | 2~7 | ﹢0.5 |

| 23*8*T | 23 | ±0.5 | 8 | ±0.3 | 2~8 | ﹢0.5 |

| 23*14*T | 23 | ±0.5 | 14 | ±0.4 | 2~12 | ﹢0.5 |

| 24*10*T | 24 | ±0.5 | 10 | ±0.3 | 2~8 | ﹢0.5 |

| 24*12*T | 24 | ±0.5 | 12 | ±0.4 | 2~6 | ﹢0.5 |

| 24*24*T | 24 | ±0.5 | 24 | ±0.4 | 2~12 | ﹢0.5 |

| 25*4*T | 25 | ±0.5 | 4 | ±0.3 | 2~8 | ﹢0.5 |

| Type Number | Dimensions(mm) | |||||

| L | L | T | ||||

| 25*6*T | 25 | ±0.5 | 6 | ±0.3 | 2~8 | ﹢0.5 |

| 25*8*T | 25 | ±0.5 | 8 | ±0.3 | 2~8 | ﹢0.5 |

| 25*9*T | 25 | ±0.5 | 9 | ±0.3 | 2~11 | ﹢0.5 |

| 25*10*T | 25 | ±0.5 | 10 | ±0.3 | 2~12 | ﹢0.5 |

| 25*11*T | 25 | ±0.5 | 11 | ±0.4 | 2~8 | ﹢0.5 |

| 25*12*T | 25 | ±0.5 | 12 | ±0.4 | 2~12 | ﹢0.5 |

| 25*15*T | 25 | ±0.5 | 15 | ±0.4 | 2~10 | ﹢0.5 |

| 25*17*T | 25 | ±0.5 | 17 | ±0.4 | 2~10 | ﹢0.5 |

| 26*4*T | 26 | ±0.5 | 4 | ±0.3 | 2~8 | ﹢0.5 |

| 26*7*T | 26 | ±0.5 | 7 | ±0.3 | 2~8 | ﹢0.5 |

| 26*8*T | 26 | ±0.5 | 8 | ±0.3 | 2~8 | ﹢0.5 |

| 26*9*T | 26 | ±0.5 | 9 | ±0.3 | 2~8 | ﹢0.5 |

| 27*5*T | 27 | ±0.5 | 5 | ±0.3 | 2~8 | ﹢0.5 |

| 27*7*T | 27 | ±0.5 | 7 | ±0.3 | 2~7 | ﹢0.5 |

| 27*12*T | 27 | ±0.5 | 12 | ±0.4 | 2~8 | ﹢0.5 |

| 28*11*T | 28 | ±0.5 | 11 | ±0.4 | 2~12 | ﹢0.5 |

| 28*12*T | 28 | ±0.5 | 12 | ±0.4 | 2~8 | ﹢0.5 |

| 28*14*T | 28 | ±0.5 | 14 | ±0.4 | 2~14 | ﹢0.5 |

| 28*15*T | 28 | ±0.5 | 15 | ±0.4 | 2~8 | ﹢0.5 |

| 29*3*T | 29 | ±0.5 | 3 | ±0.3 | 2~8 | ﹢0.5 |

| 30*3*T | 30 | ±0.5 | 3 | ±0.3 | 2~8 | ﹢0.5 |

| 30*5*T | 30 | ±0.5 | 5 | ±0.3 | 2~8 | ﹢0.5 |

| 30*6*T | 30 | ±0.5 | 6 | ±0.3 | 2~10 | ﹢0.5 |

| 30*9*T | 30 | ±0.5 | 9 | ±0.3 | 2~11 | ﹢0.5 |

| 30*10*T | 30 | ±0.5 | 10 | ±0.3 | 2~12 | ﹢0.5 |

| 30*16*T | 30 | ±0.5 | 16 | ±0.4 | 2~12 | ﹢0.5 |

| 30*20*T | 30 | ±0.5 | 20 | ±0.4 | 2~10 | ﹢0.5 |

| 30*25*T | 30 | ±0.5 | 25 | ±0.5 | 2~14 | ﹢0.5 |

| 31*4*T | 31 | ±0.5 | 4 | ±0.3 | 2~7 | ﹢0.5 |

| 31*5*T | 31 | ±0.5 | 5 | ±0.3 | 2~13 | ﹢0.5 |

| 31*6*T | 31 | ±0.5 | 6 | ±0.3 | 2~10 | ﹢0.5 |

| 31*21*T | 31 | ±0.5 | 21 | ±0.4 | 2~12 | ﹢0.5 |

| 32*12*T | 32 | ±0.5 | 12 | ±0.4 | 2~15 | ﹢0.5 |

| 33*5*T | 33 | ±0.5 | 5 | ±0.3 | 2~12 | ﹢0.5 |

| 33*12*T | 33 | ±0.5 | 12 | ±0.4 | 2~7 | ﹢0.5 |

| 33*18*T | 33 | ±0.5 | 18 | ±0.4 | 2~11 | ﹢0.5 |

| 33*22*T | 33 | ±0.5 | 22 | ±0.4 | 2~10 | ﹢0.5 |

| 35*4*T | 35 | ±0.5 | 4 | ±0.3 | 2~8 | ﹢0.5 |

| 35*8*T | 35 | ±0.5 | 8 | ±0.3 | 2~12 | ﹢0.5 |

| 35*10*T | 35 | ±0.5 | 10 | ±0.3 | 2~14 | ﹢0.5 |

| Type Number | Dimensions(mm) | |||||

| L | L | T | ||||

| 35*13*T | 35 | ±0.7 | 13 | ±0.4 | 2~12 | ﹢0.5 |

| 35*20*T | 35 | ±0.7 | 20 | ±0.4 | 2~12 | ﹢0.5 |

| 36*5*T | 36 | ±0.7 | 5 | ±0.3 | 2~12 | ﹢0.5 |

| 36*7*T | 36 | ±0.7 | 7 | ±0.3 | 2~10 | ﹢0.5 |

| 36*9*T | 36 | ±0.7 | 9 | ±0.3 | 2~7 | ﹢0.5 |

| 38*24*T | 38 | ±0.7 | 24 | ±0.4 | 2~11 | ﹢0.5 |

| 39*4*T | 39 | ±0.7 | 4 | ±0.3 | 2~8 | ﹢0.5 |

| 39*28*T | 39 | ±0.7 | 28 | ﹢0.5 | 2~12 | ﹢0.5 |

| 40*2*T | 40 | ±0.7 | 2 | ±0.3 | 2~10 | ﹢0.5 |

| 40*4*T | 40 | ±0.7 | 4 | ±0.3 | 2~12 | ﹢0.5 |

| 40*6*T | 40 | ±0.7 | 6 | ±0.3 | 2~12 | ﹢0.5 |

| 40*10*T | 40 | ±0.7 | 10 | ±0.2 | 2~11 | ﹢0.5 |

| 40*15*T | 40 | ±0.7 | 15 | ±0.4 | 2~15 | ﹢0.5 |

| 40*16*T | 40 | ±0.7 | 16 | ±0.4 | 2~12 | ﹢0.5 |

| 42*20*T | 42 | ±0.7 | 20 | ±0.4 | 2~11 | ﹢0.5 |

| 43*9*T | 43 | ±0.7 | 9 | ±0.3 | 2~12 | ﹢0.5 |

| 45*6*T | 45 | ±0.7 | 6 | ±0.3 | 2~12 | ﹢0.5 |

| 47*2*T | 47 | ±0.7 | 2 | ±0.3 | 2~12 | ﹢0.5 |

| 50*2*T | 50 | ±1.5 | 2 | ﹢0.3 | 2~10 | ﹢0.5 |

| 50*3*T | 50 | ±1.5 | 3 | ﹢0.3 | 2~12 | ﹢0.5 |

| 50*4*T | 50 | ±1.5 | 4 | ﹢0.3 | 2~11 | ﹢0.5 |

| 50*5*T | 50 | ±1.5 | 5 | ﹢0.3 | 2~11 | ﹢0.5 |

| 50*6*T | 50 | ±1.5 | 6 | ﹢0.3 | 2~14 | ﹢0.5 |

| 50*7*T | 50 | ±1.5 | 7 | ﹢0.4 | 2~8 | ﹢0.5 |

| 50*8*T | 50 | ±1.5 | 8 | ﹢0.4 | 2~12 | ﹢0.5 |

| 50*9*T | 50 | ±1.5 | 9 | ﹢0.4 | 2~10 | ﹢0.5 |

| 50*10*T | 50 | ±1.5 | 10 | ﹢0.4 | 2~12 | ﹢0.5 |

| 50*12*T | 50 | ±1.5 | 12 | ﹢0.5 | 2~12 | ﹢0.5 |

| 50*15*T | 50 | ±1.5 | 15 | ﹢0.5 | 2~15 | ﹢0.5 |

| 51*3*T | 51 | ±1.5 | 3 | ﹢0.3 | 2~12 | ﹢0.5 |

| 51*4*T | 51 | ±1.5 | 4 | ﹢0.3 | 2~10 | ﹢0.5 |

| 51*5*T | 51 | ±1.5 | 5 | ﹢0.3 | 2~12 | ﹢0.5 |

| 51*12*T | 51 | ±1.5 | 12 | ﹢0.5 | 2~12 | ﹢0.5 |

| 52*3*T | 52 | ±1.5 | 3 | ﹢0.3 | 2~12 | ﹢0.5 |

| Type Number | Dimensions(mm) | |||||

| L | L | T | ||||

| 52*4*T | 52 | ±1.5 | 4 | ﹢0.3 | 2~12 | ﹢0.5 |

| 55*6*T | 55 | ±1.5 | 6 | ﹢0.3 | 2~12 | ﹢0.5 |

| 55*20*T | 55 | ±1.5 | 20 | ﹢0.5 | 2~12 | ﹢0.5 |

| 55*30*T | 55 | ±1.5 | 30 | ±1.0 | 2~11 | ﹢0.5 |

| 60*2*T | 60 | ±1.5 | 2 | ±0.3 | 2~13 | ﹢0.5 |

| 60*3*T | 60 | ±1.5 | 3 | ±0.3 | 2~10 | ﹢0.5 |

| 60*6*T | 60 | ±1.5 | 6 | ±0.3 | 2~10 | ﹢0.5 |

| 60*30*T | 60 | ±1.5 | 30 | ﹢0.6 | 2~11 | ﹢0.5 |

| 65*35*T | 65 | ﹢2.0 | 35 | ﹢0.8 | 2~15 | ﹢0.5 |

| 70*4*T | 70 | ﹢2.0 | 4 | ±0.3 | 2~13 | ﹢0.5 |

| 70*7*T | 70 | ﹢2.0 | 7 | ±0.4 | 2~11 | ﹢0.5 |

| 80*2*T | 80 | ﹢2.0 | 2 | ±0.3 | 2~12 | ﹢0.5 |

| 80*7*T | 80 | ﹢2.0 | 7 | ±0.4 | 2~10 | ﹢0.5 |

| 81*3*T | 81 | ﹢2.0 | 3 | ±0.3 | 2~13 | ﹢0.5 |

| 81*4*T | 81 | ﹢2.0 | 4 | ±0.3 | 2~11 | ﹢0.5 |

| 87*27*T | 87 | ﹢2.0 | 27 | ﹢0.6 | 2~11 | ﹢0.5 |

| 100*2*T | 100 | ﹢5.0 | 2 | ﹢0.5 | 2~12 | ﹢0.5 |

| 100*6*T | 100 | ﹢2.5 | 6 | ﹢0.5 | 2~12 | ﹢0.5 |

| 100*8*T | 100 | ﹢2.5 | 8 | ﹢0.5 | 2~12 | ﹢0.5 |

| 103*2.5*T | 103 | ﹢5.0 | 2.5 | ﹢0.5 | 2~12 | ﹢0.5 |

| 103*3*T | 103 | ﹢5.0 | 3 | ﹢0.5 | 2~12 | ﹢0.5 |

| 103*4*T | 103 | ﹢5.0 | 4 | ﹢0.5 | 2~12 | ﹢0.5 |

| 103*5*T | 103 | ﹢5.0 | 5 | ﹢0.5 | 2~12 | ﹢0.5 |

| 110*2.5*T | 110 | ﹢2.5 | 2.5 | ﹢0.5 | 2~12 | ﹢0.5 |

| 110*3*T | 110 | ﹢2.5 | 3 | ﹢0.5 | 2~12 | ﹢0.5 |

| 110*4*T | 110 | ﹢2.5 | 4 | ﹢0.5 | 2~12 | ﹢0.5 |

| 110*5*T | 110 | ﹢2.5 | 5 | ﹢0.5 | 2~12 | ﹢0.5 |

| 110*6*T | 110 | ﹢2.5 | 6 | ﹢0.5 | 2~12 | ﹢0.5 |

| 120*3*T | 120 | ﹢2.5 | 3 | ﹢0.5 | 2~12 | ﹢0.5 |

| 120*4*T | 120 | ﹢2.5 | 4 | ﹢0.5 | 2~12 | ﹢0.5 |

| 120*5*T | 120 | ﹢2.5 | 5 | ﹢0.5 | 2~12 | ﹢0.5 |

| 140*2*T | 140 | ﹢2.5 | 2 | ﹢0.5 | 2~12 | ﹢0.5 |

| 140*3*T | 140 | ﹢2.5 | 3 | ﹢0.5 | 2~12 | ﹢0.5 |

| 140*4*T | 140 | ﹢2.5 | 4 | ﹢0.5 | 2~12 | ﹢0.5 |

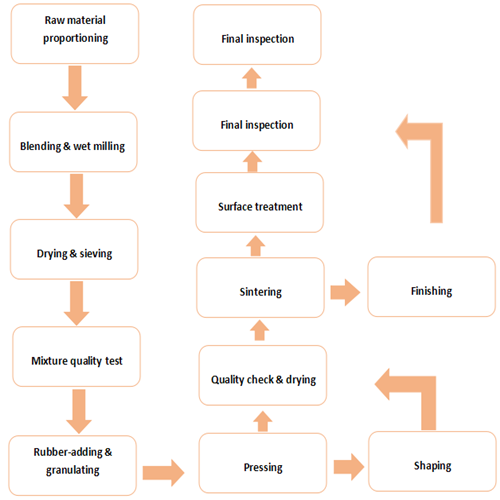

Production Process

FAQ

A1: What is your main product?

Q1: The main product include tungsten carbide bar, carbide wire

drawing die, carbide drill bit button, carbide SS10 tips, carbide

strip and carbide plate, anvil, carbide inserts, and any other

carbide products and customized products.

A2: Do you have certification on your products?

Q2: ISO 9001:2018

A3: What is about your general delivery date?

Q3: Normally 7-15 workdays .

A4: What is your packing?

Q4: We use standard export packing and customization is available.

A5: Can I get the samples?

Q5: Sure, contact us directly.