Zigong Xingyu Cemented Carbide Dies & Tools Co., Ltd. |

|

Custom Tungsten Carbide Progressive Die Deep Wire Drawing Die

Application

Cemented carbide wire drawing die as a tool material has been

increasingly used for cutting tools, wear-resistant tools,

impact-resistant tools, and other products with special purpose.

Cemented carbide was first used in stretching mold area and has

gone though cast iron mold, alloy steel mold, diamond dies,

cemented carbide dies, polycrystalline module die and other

developmental stages. With the property of high wear resistance,

good polishing performance, low friction coefficient, etc.,

cemented carbide drawing die has been a substitute of steel mould

which is used to stretching steel and non-ferrous metal.

Tungsten Carbide Wire Guide Wire Drawing Dies

We choose best tungsten carbide core, to make the drawing dies with

high hardness,Good good thermal conductivity, low coefficient of

friction. It is suitable for drawing black metal,wire drawing,

large size of tube, low working environment required.

Advantages

1. simple manufacture

2. corrosion resistance

3. strong impact resistance

4. quite low manufacturing cost

The Tungsten carbide Wire Drawing Die is a tool that consists of highly polished, shaped hole through which wire is drawn to reduce its diameter.

Grade List

| Grade | Co (wt%) | Density (g/cm³) | Hardness (HRA) | TRS (≥N/mm²) | Applications |

| XC100 | 5.8-6.2 | 14.6-15.0 | 91.5-92.5 | 2000 | Wire drawing dies for wear-resistance impact-resistance |

| XC101 | 5.8-6.2 | 14.6-15.0 | 91.5-92.5 | 2500 | |

| XC200 | 7.8-8.2 | 14.5-14.9 | 91.0-92.0 | 2100 | |

| XC201 | 7.8-8.2 | 13.5-14.9 | 91.0-92.0 | 2800 | |

| XC300 | 9.8-10.3 | 14.2-14.6 | 90.5-91.5 | 2600 | |

| XC301 | 9.8-10.3 | 14.2-14.6 | 90.5-91.5 | 3200 | |

| XC500 | 14.7-15.3 | 13.9-14.2 | 87.0-88.0 | 2600 | Stamping dies for impact-resistance |

| XC501 | 14.7-15.3 | 13.9-14.2 | 87.0-88.0 | 2800 | |

| XC800 | 19.5-20.5 | 13.4-13.6 | 83.0-84.0 | 2600 | |

| XC8001 | 19.5-20.5 | 13.4-13.6 | 83.0-84.0 | 3000 | |

| XC900 | 23.0-23.5 | 13.1-13.4 | 82.5-83.5 | 2400 | |

| XC901 | 23.0-23.5 | 13.1-13.4 | 82.5-83.5 | 2600 | |

| Grade | Co+Ni (wt%) | Density (g/cm³) | Hardness (HRA) | TRS (≥N/mm²) | Applications |

| XCN61 | 16.0-17.0 | 13.5-14.0 | 83.5-84.5 | 3200 | Stamping dies for High temperature-resistance |

| XCN71 | 17.0-18.0 | 13.3-13.8 | 82.0-83.0 | 3000 |

| Dimension | |||||

| d | l | d1 | h | h1 | ll |

| 8 | 6 | 0.1-1.0 | 0.1-10.6 | 1.0-2.0 | 0.8-1.2 |

| 10 | 8 | 0.1-1.2 | 0.1-0.8 | 1.5-4.0 | 1.0-1.8 |

| 12 | 10 | 0.2-2.0 | 0.1-1.5 | 2.0-5.0 | 1.6-2.5 |

| 14 | 12 | 0.4-2.5 | 0.2-2.0 | 4.0-5.0 | 1.8-2.5 |

| 16 | 13 | 0.5-3.0 | 0.2-2.5 | 4.0-5.5 | 2.0-3.0 |

| 20 | 17 | 1.0-6.0 | 0.6-3.0 | 5.0-8.0 | 2.5-4.0 |

| 25 | 20 | 2.0-8.5 | 1.0-3.5 | 7.0-10.0 | 3.0-4.5 |

| 30 | 24 | 3.5-12.0 | 2.0-4.0 | 8.0-12.0 | 3.0-5.0 |

| Notice: α=8°10° 12° 14°16°18° β=40° 60° 90° γ=60° 75° 90° | |||||

| Dimension | |||||

| ΦD | b | H | α | β | γ |

| 6.0-8.0 | 0..2 | 4.0-6.0 | 10° | 40° | 60° |

| 6.0-8.0 | 0.4-0.8 | 4.0-6.0 | 40° | * | |

| 8.0-22.0 | 0.4-5.7 | 6.0-20.0 | 10°-14° | 40° | |

| 8.0-26.0 | 0.4-8.0 | 6.0-16.0 | 16° | 40° | |

| 30.0-140.0 | 3.7-84.0 | 21.0-50.0 | 14°-20° | * | |

| Dimension | |||||

| ΦD | Φd | H | α | γ | R |

| 16.0-110.0 | 2.0-60.0 | 14-52 | 3° | 60° | 40 |

| 16.0-110.0 | 20.0-62.0 | 35-45 | 4° | 15.0-40.0 | |

| 16.0-110.0 | 2.8-88.0 | 13-50 | 24° | 3.0-10.0 | |

| 16.0-110.0 | 20.0-70.0 | 32-55 | * | 3.0-40.0 | |

| Dimension | |||||

| d | l | A | h | h1 | ll |

| 16 | 12 | 1.5-2.5 | 0.5-1.5 | 4.0-6.0 | 1.0-2.0 |

| 22 | 18 | 2.0-4.0 | 1.0-2.0 | 5.5-9.0 | 1.5-2.5 |

| 30 | 21 | 3.5-7.0 | 1.5-2.5 | 8.0-12.0 | 1.5-2.5 |

| 35 | 25 | 6.5-10.0 | 2.5-3.5 | 10.0-14.0 | 2.0-4.0 |

| 45 | 25 | 8.0-15.0 | 3.0-4.0 | 10.0-14.0 | 2.0-4.0 |

| 50 | 28 | 12.0-20.0 | 3.5-4.5 | 12.0-16.0 | 2.0-4.0 |

| 60 | 30 | 18.0-25.0 | 4.0-5.5 | 12.0-16.0 | 3.0-5.0 |

| 65 | 32 | 22.0-30.0 | 5.0-7.0 | 12.0-16.0 | 4.0-6.0 |

| 70 | 35 | 26.0-35.0 | 6.0-9.0 | 14.0-18.0 | 5.0-7.0 |

| 80 | 35 | 30.0-40.0 | 6.0-9.0 | 14.0-18.0 | 5.0-7.0 |

| 90 | 40 | 35.0-45.0 | 6.0-9.0 | 14.0-18.0 | 5.0-7.0 |

| 100 | 40 | 40.0-50.0 | 6.0-9.0 | 14.0-18.0 | 5.0-7.0 |

| 120 | 45 | 45.0-55.0 | 6.0-9.0 | 14.0-18.0 | 5.0-7.0 |

| Note:α=14° 16° 20° β=40° γ=60° | |||||

| Dimension | ||||||

| d | l | A | B | h | h1 | ll |

| 20 | 12 | 1.5-3.5 | 0.5-1.5 | 1.5-2.5 | 3.0-5.0 | 1.5-2.5 |

| 22 | 12 | 3.0-5.0 | 0.5-2.0 | 1.5-2.5 | 3.0-5.0 | 1.5-2.5 |

| 25 | 15 | 3.5-7.0 | 0.5-4.0 | 2.0-3.0 | 4.0-6.0 | 2.0-3.0 |

| 32 | 16 | 5.0-9.0 | 1.5-4.0 | 2.0-3.0 | 4.0-6.0 | 2.0-3.0 |

| 35 | 18 | 7.0-12.0 | 1.0-6.0 | 2.0-3.0 | 5.0-8.0 | 2.0-3.0 |

| 25 | 7.0-12.0 | 2.0-8.0 | 2.5-3.5 | 7.0-13.0 | 2.5-3.5 | |

| 45 | 20 | 10.0-15.0 | 1.0-7.0 | 2.5-3.5 | 5.0-8.0 | 2.5-3.5 |

| 25 | 10.0-15.0 | 4.0-10.0 | 3.0-4.0 | 7.0-14.0 | 2.5-3.5 | |

| 50 | 20 | 12.0-24.0 | 1.0-8.0 | 2.5-3.5 | 5.0-96.0 | 2.5-3.5 |

| 28 | 12.0-24.0 | 6.0-16.0 | 3.0-4.0 | 8.0-15.0 | 2.5-3.5 | |

| 60 | 20 | 18.0-32.0 | 1.0-9.0 | 2.5-4.0 | 5.0-10.0 | 2.5-3.5 |

| 30 | 18.0-32.0 | 7.0-16.0 | 4.0-6.0 | 8.0-16.0 | 3.0-5.0 | |

| Note: α=° 14°18° β=40° 60° γ=60° | ||||||

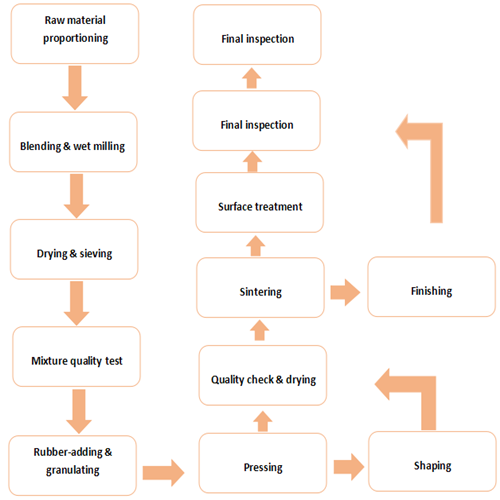

Production Process

FAQ

Q1: How long is your delivery period?

A1: It depends on specific conditions. However, it could be 10 to 15 days on average.

Q2: Do you offer samples?

A2: Yes, we do offer samples. However, buyers need to pay for the freight charge. In addition, whether samples are free or not depends on the quantity you buy.

Q3: How do you pack the products?

A3: In general, we use wood, plastic or carton boxes. We also put some soft materials inside to prevent possible damage on products.

Q4: How much advance payment do I need to make?

A4: If the products you buy are in stock, you need to make full payment; if the products are out of stock, you need to make about 50 percent of full payment and then we will start the production process. However, you still need to pay the rest of charges before we deliver the products.

Q5: What kinds of payment do you accept?

A5: In addition to the patterns of payment shown above, you can discuss with us about in which way you would like to pay.

Please contact us if you have any other questions.