Dongguan Fanchi Mold Technology Co., Ltd |

|

Verified Suppliers

|

|

Our Punch Holders are made of high-quality materials such as YG6, YG8, YG10, and YG15, among others. These materials are known for their durability, wear resistance, and strength. The heat treatment process applied to our Punch Holders enhances mold hardness and wear resistance, ensuring that they can withstand even the most demanding applications.

Our Punch Holders are perfect for use with CNC machining equipment. CNC machining is a process used to create precision parts by removing material from a solid block using cutting tools. Our Punch Holders are designed to work seamlessly with CNC lathe manufacturers to create accurate and reliable parts.

In addition to heat treatment, our Punch Holders are also coated with high-performance coatings. These coatings enhance mold wear and corrosion resistance, ensuring that our products last longer and perform better than competitor products.

Our Punch Holders are available in standard sizes to fit a wide range of applications. However, we also offer non-standard sizes for specific applications. Our products are designed to meet the needs of our customers and to provide the best solutions for their CNC lathe tooling needs.

Overall, our Punch Holders are the perfect solution for anyone looking for high-quality CNC lathe tooling. With heat treatment, high-performance coatings, and a wide range of sizes available, our products are designed to meet the needs of any application. So why wait? Order your Punch Holders today and experience the difference that high-quality CNC lathe tooling can make!

| Product Name: | Cutting-Edge Machinery for Advanced Machining CNC Lathes and Grinding with Punch Holders |

| Product Category: | Punch Holders |

| Product Material: | Tungsten Carbide,Steel |

| Size: | Standard Or Non-standard |

| Surface: | TiN/TiCN/AlTiN |

| High-Speed Cutting: | Adopts high-speed tools to improve production efficiency and surface quality |

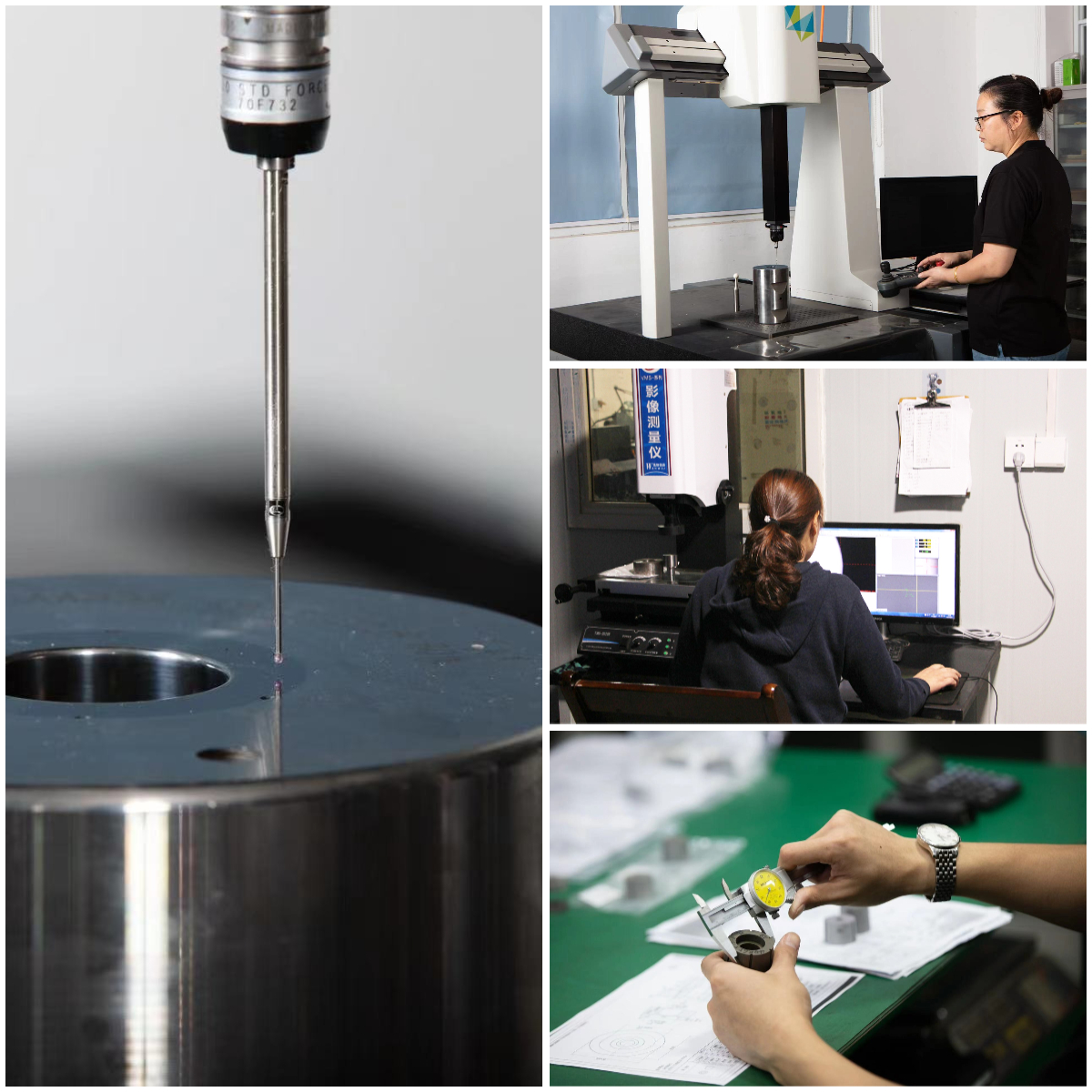

| QC: | 1.Incoming material will be checked carefully before production. 2.Strict processing quality control 3.100% inspection before shipment |

| Electric Discharge Machining (EDM): | Uses EDM machines for precise cutting of hard materials, especially for complex shapes |

| Manufacturing Technique: | CAD/CAM Mold Design, CNC Machining, Electric Discharge Machining (EDM), Heat Treatment, High-Speed Cutting, Mold Assembly, Multi-Station Cold Forging, Surface Coating |

| Drawing: | 2D/3D/CAD |

Our company is one of the leading cnc grinding machine manufacturers, offering a wide range of cnc machining products including lathe and milling machine. Our Punch Holders are manufactured using advanced techniques such as CAD/CAM Mold Design, CNC Machining, Electric Discharge Machining (EDM), and High-Speed Cutting. We also ensure strict quality control measures are taken throughout our manufacturing process to deliver high-quality products that meet the needs of our customers.

The Henghui Punch Holders are advanced tools that are designed to hold and guide punches during punching operations. These holders are made using advanced CNC machining technology that employs CNC lathe cutting and CNC milling machines. These machines are used to precisely mill, turn and grind mold components to ensure the highest levels of accuracy and precision.

The Henghui Punch Holders are ideal for use in a wide range of product application occasions and scenarios. They are commonly used in the manufacturing industry for the production of metal parts, such as sheet metal, automotive parts, and machine parts. These holders are also suitable for use in the electronics industry, where they are used to punch holes in circuit boards and other electronic components.

The Henghui Punch Holders are made from high-quality materials that have been heat-treated to enhance mold hardness and wear resistance. This makes them ideal for use in harsh environments, where they can withstand high levels of stress and wear. They are available in a range of grades, including YG6, YG8, YG10X, and YG20C, which are suitable for use in different types of punching operations.

The Henghui Punch Holders are certified for quality and reliability, and they are manufactured in Guangdong, China. They are available for purchase with a minimum order quantity of 1, and they are priced between USD1-10/PCS. Payment terms are T/T, and the supply ability is 1000PCS/DAYS. The delivery time is between 15-20 WORK DAYS, and the packaging details are CARTON.

The Henghui Punch Holders are suitable for use in a range of product application occasions and scenarios. They are commonly used in the manufacturing industry for the production of metal parts, such as sheet metal, automotive parts, and machine parts. They are also suitable for use in the electronics industry, where they are used to punch holes in circuit boards and other electronic components.

The Henghui Punch Holders are made using multi-station cold forging technology, which involves one-step forming of screw heads and threads. This process ensures that the holders are strong and durable, and that they can withstand high levels of stress and wear.

Overall, the Henghui Punch Holders are an essential tool for any manufacturing or electronics operation that requires precise punching operations. They are made using advanced CNC machining technology and multi-station cold forging, which ensures the highest levels of accuracy, precision, and durability.

Our Punch Holders are designed to be durable and long-lasting, but we understand that sometimes issues may arise. Our technical support team is available to assist with any questions or concerns regarding the product's functionality.

In addition, we offer a variety of services to ensure the best experience for our customers. This includes product installation assistance, product training, and ongoing maintenance and repair services.

We are committed to providing top-notch support and services to our customers and are always available to assist in any way we can.

Product Packaging:

Shipping:

Q: What is the brand name of this product?

A: The brand name is Henghui.

Q: What is the minimum order quantity for this product?

A: The minimum order quantity is 1.

Q: What is the price range of this product?

A: The price range is USD1-10/PCS.

Q: What is the delivery time for this product?

A: The delivery time is 15-20 work days.

Q: Where is this product manufactured?

A: This product is manufactured in Guangdong.