Jiangsu TOM Intelligent Equipment Co., Ltd., |

|

Verified Suppliers

|

|

LP-7 PLC controlled Fully Automatic High Speed Bottle Unscrambler

Major characteristics:

This machine is controlled by PLC and touch screen ,operators can adjust all parameters on the touch screen .frequency control the speed.

Operators only need to change the turntable of the unscramble box in order to change the specification ,other parts can be adjusted.

Technical Parameter:

| No. | Items | Performance |

| 01 | Capacity | 6000 bottles/hour |

| 02 | Bottle diameter | Φ30mm~Φ100mm |

| 03 | Bottle height | 100mm~250mm |

| 04 | Power supply | AC 220V, 50Hz, single phase |

| 05 | Power | 1.1 Kw |

| 06 | Machine dimension (L ×W×H) | 3000mm*1500mm*1500mm |

| 07 | Machine weight | About 1300 Kg |

Machine details:

1. Compact structure, simple, small floor space, convenient debugging and adjustment, good versatility, 50-1000ml bottles can be universal.

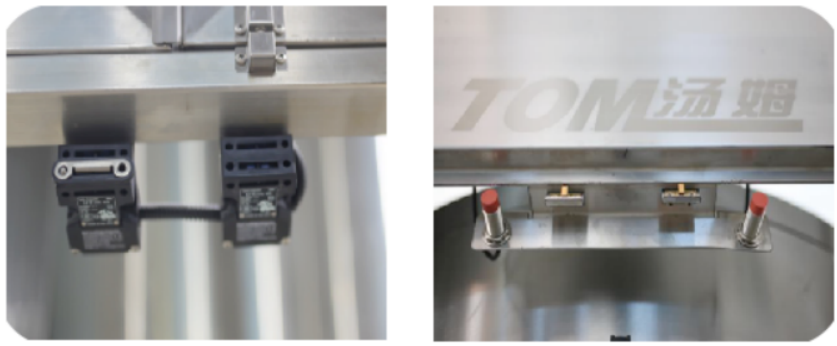

2. All plexiglass enclosures are equipped with induction switch. The plexiglass enclosures shall be completely closed to start the machine.

3. When changing specifications, no mold needs to be replaced. 50-1000ml bottles can be used.It is convenient and quick to adjust, only need to change the number of belt in the turntable and adjust the space between the parts.(each belt is driven by an independent servo motor, which greatly improves the output, quality and stability)

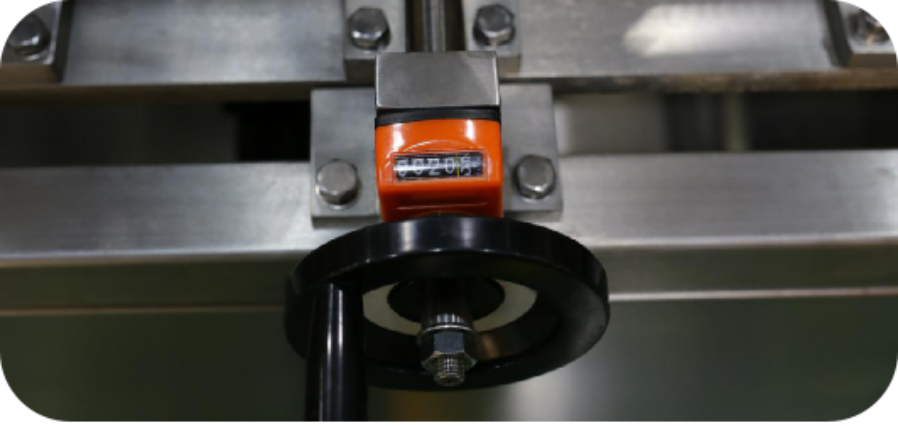

4. all adjustments have scale adjustment, convenient and fast.

5. Equipped with coordinated photoelectricity, when the bottle of the conveyor belt in the back lane is congested, the bottle is suspended. When the conveyor belt is smooth, the bottle is bottled again to achieve perfect connection with the packaging equipment of the rear channel; the unmanned operation of the whole machine can be realized.

6.Equipped with a bottle-removing device, when the bottle is taken out, after the bottle is inverted, the photoelectric detection detects the bottle, and the cylinder kicks the bottle into the bottle collection bucket.

7, The bottle-receiving part adopts three-stage synchronous belt conveying, and the imported imported seamless timing belt has smoother surface and less friction than the original tape, which greatly reduces damage to the bottle body or damage to the label, and the service life is increased.

8,stable operation, do not hurt the bottle.

9,Automatic bottle-opening function, only need to pour the bottle into the bottle machine, the test light is installed in the turntable, and the bottle is automatically bottled when the bottle is insufficient. When the bottle is enough, the bottle is stopped, and no bottle is automatically alarmed in the bottle machine without manual intervention.

Electrical parts:

The electrical part are in top side of machine, can prevent water

and material inside it, safety and environmental.

Safety door:

All doors are equipped with photoelectric induction, emergency door opening, machine shutdown alarm to ensure personnel safety.

Drawing for Reference

Packaging & Shipping

1. the machine is packked by non-fumigation wooden case, and for keeping the wooden case more secure, we inserted the iron support inside wooden case, makes it suitable for long-term sea delivery.

Ware hourse for finished packed machines:

Loading machines into container:

We have a professional logistics team responsible for shipping

Company Overview--Jiangsu Tom Group