Shanxi Taigang Steel Manufacturing Co.,Ltd |

|

Verified Suppliers

|

|

Description

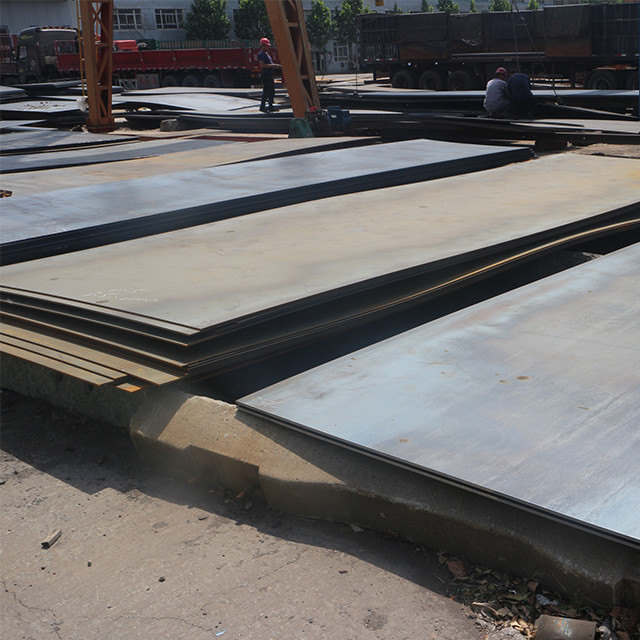

ASTM A36/A36M 8mm 2200mm*10000mm Carbon Steel Sheet For

Shipbuilding

| Standard | ASTM, AISI, JIS, EN, DIN |

| Thickness | 3mm-380mm |

| Width | 600mm-2500mm |

| Length | As your requirement |

| Tolerance | As Chinese standard |

| Surface Treatment | Painted, Olied |

| Grade | 16Mo3, Q215, Q345, SS400, SS490, etc. |

| Process Method | Hot roll, cold roll, cold draw, etc. |

| Certificate | BV, ISO9001:2008, MTC |

| Packaging | Standard exporting packing or as client's requirement |

A36 carbon steel is a widely used grade of low carbon steel that is

characterized by its excellent mechanical properties and

versatility. Here is a description of A36 carbon steel:

A36 carbon steel has good machinability, allowing it to be easily

shaped, cut, drilled, and welded. It can be formed into various

shapes and structures using common manufacturing processes.

A36 carbon steel has excellent weldability and can be welded using

various methods such as arc welding, resistance welding, and gas

welding. Preheating and post-weld treatments may be required to

minimize the risk of cracking and achieve optimal weld quality.

A36 carbon steel exhibits good ductility, enabling it to be formed

into different shapes without cracking or breaking. It can be bent,

rolled, and formed into plates, sheets, bars, and structural

components.

A36 carbon steel is not highly resistant to corrosion and may rust

if exposed to moisture and certain corrosive environments. To

enhance its corrosion resistance, protective coatings or surface

treatments can be applied.

Chemical Composition

| Grade | C | Si | Mn | P | S | Cu |

| A36 | ≤0.25 | ≤0.40 | ≤0.80-1.20 | ≤0.04 | ≤0.05 | ≥0.20 |

Mechanical Properties

| Grade | Tensile Strength | Yield Strength | Percentage Elongation |

| A36 | ≥250 | 400-550 | ≥20 |

Application

A36 carbon steel is widely used in the construction industry for

structural components such as beams, columns, and girders. Its

strength and ductility make it suitable for supporting heavy loads

and withstanding the stresses encountered in buildings, bridges,

and other structures.

A36 carbon steel is utilized in the manufacturing and fabrication

of a wide range of products. It is commonly used to produce parts

and components for machinery, equipment, and vehicles. Its

machinability and formability allow for efficient fabrication

processes such as cutting, bending, and welding.

Carbon steel is commonly used in shipbuilding due to its excellent

mechanical properties, weldability, and cost-effectiveness. It is

utilized in various structural components and equipment within

ships. Here are some common applications of carbon steel in

shipbuilding:

1. Hull Structure: Carbon steel plates are extensively used in the

construction of the ship's hull structure. These plates provide the

necessary strength and integrity to withstand the harsh marine

environment and the loads experienced during ship operations. They

are typically used for the main hull, decks, bulkheads, and

superstructures.

2. Frames and Bulkheads: Carbon steel is employed in the

fabrication of ship frames and bulkheads, which provide structural

support and compartmentalization within the ship. These components

help to distribute loads and enhance the overall strength and

stability of the vessel.

3. Ship Machinery and Equipment: Carbon steel is used in the

construction of various machinery and equipment onboard ships. This

includes components such as propulsion systems, engine supports,

shafts, brackets, and piping systems. Carbon steel's mechanical

properties and weldability make it suitable for withstanding the

vibrations, stresses, and corrosive conditions encountered in

marine environments.

It's worth noting that certain areas of the ship, such as those

exposed to seawater or requiring higher corrosion resistance, may

utilize specialized grades of carbon steel or other materials.

Additionally, proper surface preparation, coatings, and maintenance

practices are essential to enhance the corrosion resistance of

carbon steel in marine environments.

Advantage

Carbon steel offers several advantages that make it a popular

choice in various applications. Here are some key advantages of

carbon steel:

1. High Strength: Carbon steel exhibits excellent strength

properties, making it suitable for structural applications where

high strength is required. It can withstand heavy loads and resist

deformation, providing structural integrity and stability.

2. Cost-Effective: Carbon steel is relatively affordable

compared to many other types of metals and alloys. It offers a

favorable balance between cost and performance, making it a

cost-effective option for a wide range of applications.

3. Wide Availability: Carbon steel is widely available and

easily accessible in the market. It is produced by numerous

manufacturers and is readily available in various forms such as

sheets, plates, bars, and pipes. This availability makes it

convenient for sourcing and reduces lead times.

FAQ

Q1: What is A36 carbon steel sheet?

A1: A36 carbon steel sheet refers to a specific grade of low

carbon steel sheet that is commonly used in various applications,

including construction, manufacturing, and general fabrication. It

is known for its excellent mechanical properties and versatility.

Q2: What are the dimensions of A36 carbon steel sheet?

A2: A36 carbon steel sheet is available in various dimensions,

including thickness, width, and length. The thickness of A36 carbon

steel sheet typically ranges from very thin (0.4 mm or 0.0157

inches) to relatively thick (150 mm or 5.9055 inches) or more. The

width and length can vary based on the specific requirements and

can be cut or customized as needed.

Q3: Is A36 carbon steel sheet corrosion-resistant?

A3: A36 carbon steel sheet is not highly resistant to

corrosion by itself. However, it can be protected against corrosion

by applying surface treatments such as coatings, painting, or

galvanizing. Proper maintenance and corrosion prevention practices

are important to enhance the longevity of A36 carbon steel sheet in

corrosive environments.