Cangzhou Huachen Roll Forming Machinery Co., Ltd. |

|

Verified Suppliers

|

|

Metal cold roll forming machine for roof use glazed tile roll forming machine

Technique parameters of the processing line

(1). Suitable material to process: colored armor plate with the

bending intensity of 235-550MPA;

(2). Thickness of the plate: 0.25-0.8mm;

(3). width of the plate:1250mm

(4). Effective area for use: 36";

(5). Productivity: 3-5m/min;

(6). Rollers: 15 rows;

(7). Diameter of the roller:70mm;

(8). Main motor power: 5.5KW;

(9). Hydraulic system power: 4KW;

(10). Dimensions of major structure: 7500mm*1400mm*1500mm

(approximate).

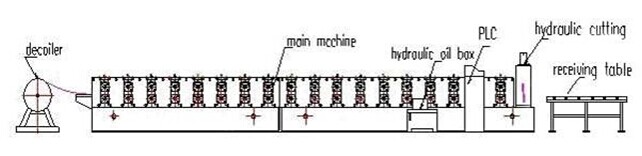

Processing technique and deployment

Processes: Manual uncoiler—Roll forming machine—PLC

system—Hydraulic system-Blade—Receiving table

Components of line:

| No. | Name | Unit | Qty | |

| 1 | Manual uncoiler | set | 1 | |

| 2 | Main machine for roll forming | set | 1 | |

| 3 | Control system | set | 1 | |

| 4 | Hydraulic system | set | 1 | |

| 5 | Blade | set | 1 | |

| 6 | Receiving table | set | 2 | |

1) Q: Are you manufacturer or trading company?

A: We are manufacturer and trading company .

2) Q: Do you provide installing and training overseas?

A: Overseas machine install and worker training services are

optional.

3) Q: How is your after sales support?

A: We provide technical support on line as well as overseas

services by skillful technicians.

4) Q: How does your factory do regarding quality control?

A: There is no tolerance regarding quality control. Quality control

complies with ISO9001. Every machine has to past testing running

before it's packed for shipment.

5) How can I trust you that machines pasted testing running before

shipping?

A: 1) We record the testing video for your reference. Or,

2) We welcome you visit us and test machine by yourself in our

factory.

6) Q: Do you sell only standard machines?

A: No. Most machines are made to order.

8) What should I provide if I`d love to customized my machine?

A: To customize machine, we`d love to know:

1. Profile drawing

2. Raw material: the width(1250mm?), thickness(0.3-0.7mm?), and

yield strength of steel coil.

3. Voltage: designed per your requirement

4. Configuration requirement: Hydraulic or manual decoiler/ stacker

Have no idea about them?

We will be glad to recommend machines ----Just let us know your country!