Cangzhou Huachen Roll Forming Machinery Co., Ltd. |

|

Verified Suppliers

|

|

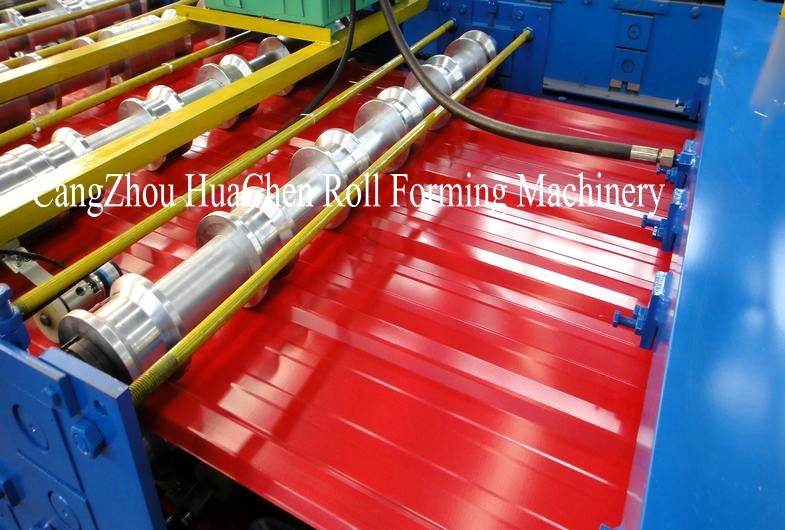

| 1. The Product Description of forming machine |

(1). Brief Introduction

The Roof Panels made by our Roll Forming Machine have beautiful appearance and bright color.

They are widely used in gardens, factories, resorts, hotels, exhibition halls, vacationlands,

ancient architectures and modern villas.

(2). Working Flow of Roll Forming Machine

Decoiling the sheet-Sheet guiding-Roll forming-Measure

length-Cutting the panel-Panels to the supporter

(3).Technical Detail

A. General

| Suitable Material | Q235 or equivalent |

| Material Thickness | 0.25-0.8 mm |

| Material Width | 914, 1000, 1200, 1220 or 1250, as per the drawing |

| Dimension | About 7.9*1.3*1.1m(L*W*H) , as per the drawing |

| Working Space | About 17.9*2.8m(L*W) , as per the drawing |

Length of | You can set the length according to your need. |

| Cutting | Automatically stop and cutting when it comes to the set |

B. Components Details

| Roller Material | High grade 45# steel. Hard chrome plating, 0.05mm. |

| Main Frame | 350# steel. More stable and no shaking. |

| Middle Plate | 16mm. We use thicker plates to ensure stability |

| Forming Steps | 11-16, according to the drawing. |

| Shaft Material | Φ70 mm, high grade 45# steel. |

Treating process: tempering- finish turning, | |

Cutting | Cr12, hardness HRC60-62. |

| Treating process: heat treatment- plane abrasion- wire electrode cutting. |

C. Electric Components

| Suitable Power | 380V, 50 Hz, 3 phase or according to your need. |

| Screen | 5.7 inch touch screen, easy to operate. |

| PLC | Delta DVP 14ES |

well-adapted to various conditions, such as moisture, | |

| Frequency Converter | DeltaVFD-M. It has the advantage of slowing down before cutting, |

Length | Omron, made in Japan. |

| It features with high accuracy and stability. |

| 2. More Pictures of forming machine |

| 3. The Application of forming machine |

This type of glazed tile has advantage inclouding beautiful,

classical appearance and grace taste.

It can be widely used in village, hotel, exhibition, vocation

vallage, family construction and outdoor decorate.

| 4. Other Products for Choosing |

Toppo Machinery Co.,Ltd. is a professional supplier for roll

forming machine.

We provide an extensive line of products, including: roof and wall panel machine, tile roof

machine, purline forming machine,

shutter door machine, floor decking machine and other associated

equipment.

Our roll forming machines are equipped with PLC control to ensure

high accuracy and easy operation.