Keeprecision Thermal Insulation Materials Co., Ltd. |

|

Verified Suppliers

|

|

Keeprecision-250-BL High-efficiency heat insulation board for the mold industry

Product Details

The Keeprecision-250-BL is described as a high-efficiency heat insulation board for the mold industry. This suggests that it is a specialized material designed to provide effective thermal insulation for molds used in various industrial processes.

Heat insulation boards for the mold industry are used to minimize heat transfer between the mold and its surroundings. They help to maintain stable and controlled temperatures within the mold, ensuring consistent and precise manufacturing conditions. By reducing heat loss or gain, these insulation boards can improve energy efficiency, enhance process control, and optimize product quality.

The specific properties and composition of the Keeprecision-250-BL heat insulation board are not available in my training data. However, such boards are typically made from insulating materials with low thermal conductivity. Common materials used in heat insulation boards include ceramic fibers, mineral fibers, expanded polystyrene (EPS), polyurethane foam, or other specialized insulation materials.

These insulation boards are often designed to have good dimensional stability, high-temperature resistance, low thermal expansion, and excellent insulation properties. They may also have features such as fire resistance, moisture resistance, and resistance to chemical substances encountered in the mold industry.

For detailed information about the Keeprecision-250-BL heat insulation board, including its specific properties, composition, and availability, it is recommended to contact the manufacturer or supplier directly. They will be able to provide you with the most accurate and up-to-date information regarding this particular product.

Product Specifications

| Properties | Test Standard | Unit | Value |

| Density | DIN 53479 | g/cm3 | 1.85 |

| Flexural Strength at 23°C | ISO 178 | N/mm2 | 400 |

Compressive Strength at 23°C at 200°C | ISO 604 | N/mm2 | 560 350 |

| Coeff. of Thermal Expansion | DIN 53752 | 10-6 K-1 | 15 |

| Thermal Conductivity | DIN 52612 | W/mK | 0.23 |

| Continuous Service Temperature | - | °C | 250 |

| Maximum Service Temperature | - | °C | 260 |

| Water Absorptionafter24h at 23°C | DIN 53495 | % | 0.1 |

Jiangsu Jingjing Insulation Board Thickness Tolerance Reference

| Insulation board specifications(mm) | Thickness tolerance(mm) |

| 450*400范围内 | ±0.05mm |

| 1000*1000范围内 | ±0.1mm |

| 800*1000范围内 | ±0.01~±0.03mm (Special precision requires grinding with high-precision equipment. Negotiable based on actual dimensions.) |

Feature of product

In addition to efficient thermal insulation properties, Jiangsu Jingjing's mold insulation panels are also designed for high-pressure applications and have excellent mechanical properties. This makes our insulation materials particularly suitable for the need for material stability.

Features

Thermal insulation panels are highly resistant to pressure, especially in higher temperature applications

Efficient thermal insulation

Allows you to control mold temperature more accurately and better improve product quality and production efficiency

Ensure the stable flow of thermoplastic plastics during processing and forming.

Typical application industries

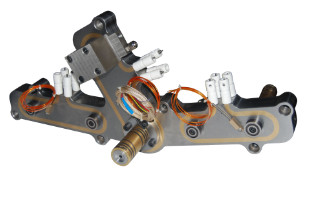

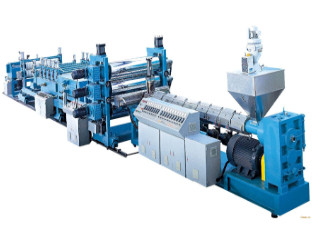

Mold insulation Thermosetting heat press insulation board

Injection molding machine heat insulation board Blow mold insulation board

Hot runner heat insulation board extruder

Jiangsu Jingjing insulation board processing and shipping time reference

Are you still worried about processing heat insulation boards, such as flying dust, affecting equipment accuracy and personnel health?

Are you still worried about product quality problems caused by processing heat insulation boards, such as cracks in holes, out-of-tolerance dimensions, product delamination, etc.

We now provide customer drawing processing services, and the

shipping time is as follows:

| Product processing status | Normal shipping time (working days) | ||||||

| Light sheet products3 working days | |||||||

| Drawing processing products | 5-7days

|

Remark:

The above is the factory shipping time. For the intermediate transportation time, please refer to the transportation time MAP on the website.

*Drawings, please try your best to provide CAD drawings so that our company can speed up the delivery time.

*If the customer is particularly urgent, please use our expedited shipping service. Please refer to the emergency shipping service on the website for details.