Hunan Tianying Drilling Machine Manufacturing Co., Ltd. |

|

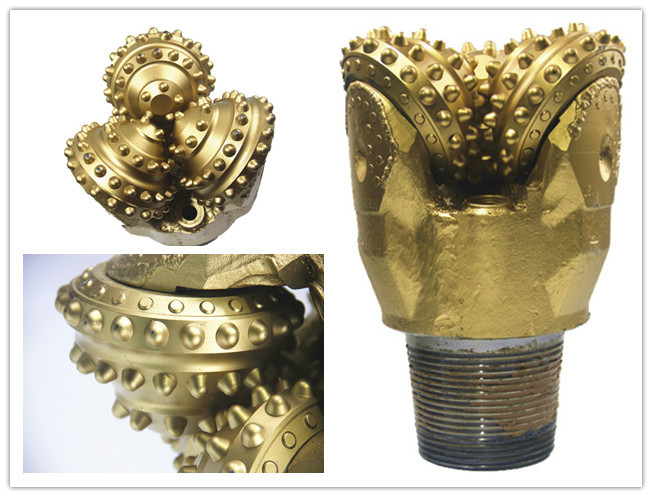

Sealed Bearing Tricone Drill Bit Can Drilling Through Soft To Ultrahard Formations

Click here for catalogueTCI DRILL BIT.pdf

What Is Tricone Drill Bit ?

Tricone Drill Bit is an perfect drilling solution for soft, medium, or hard rock formations, it is connected with the drill stem and rotates along with it, and drive cones to pressed on the rock. Each cone rotates round the axis of its leg and three cones simultaneously revolve around the bit center. The tungsten carbide inserts on the cone shell cause the formation to spall under the weight on bit and the impact load of cone rotating, the debris will be discharged out to hole by compression air. Tricone drill bits come in several different varieties, and can deal with a wide range of different rock formations. It is important to know the type of formation you are drilling in when selecting a drill bit.

All of our bits are manufactured according to strict standards, set forth by the American Petroleum Institute (API). And classified according to characteristics set forth by the International Association of Drilling Contractors (IADC).

How to read an IADC Code properly

| First Digit | TOOTH |

| 1 | Steel tooth bits for Soft Formation |

| 2 | Steel tooth bits for Medium Formation |

| 3 | Steel tooth bits for Hard Formation |

| 4 | TUNGSTEN CARBIDE INSERT BITS For varying formation hardness with 4 being the softest and 8 the hardest. |

| 5 | |

| 6 | |

| 7 | |

| 8 | |

| Second Digit | FORMATION |

| 1 | 1,2,3 and 4 are further breakdown of formation with 1 being the softest and 4 the hardest. |

| 2 | |

| 3 | |

| 4 | |

| Third Digit | BEARING/SEAL TYPE |

| 1 | Standard open bearing roller bit |

| 2 | Standard open bearing roller bit, air-cooled |

| 3 | Standard open bearing roller bit with gauge protection |

| 4 | Sealed roller bearing bit |

| 5 | Sealed roller bearing bit with gauge protection |

| 6 | Journal sealed bearing bit |

| 7 | Journal sealed bearing bit with gauge protection |

| Fourth Digit | ADDITIONAL FEATURES |

| A | Air application |

| R | Reinforced welds |

| C | Center jet |

| S | Standard steel tooth |

| D | Deviation control |

| X | Chisel insert |

| E | Extended jet |

| Y | Conical Insert |

| G | Extra gage protection |

| Z | Other insert shape |

| J | Jet Deflection |

We took the following factors into consideration when designing:

Soft to medium formation tricones employ a more round cone profile and a larger cone angle. This creates a bottom hole action of gouging and scraping.

Hard formation bits employ a smaller cone angle and a flatter cone profile. This creates a bottom hole action of crushing.

Soft formation tricones employ a higher oversize angle; thus, escalating gage action and cone diameter.

Hard formation bits have very little or no oversize angle. This reduces the action on gage and also reaming of gage inserts.

Application

Tricone drill bit is the best all-purpose drill bit and can be used for many different types of rock formations, such as Soft Rock Formations (consist mainly of sand, clay, limestone or shale), Medium Rock Formations (calcites, dolomites, hard limestones, and some hard shale), Hard and Abrasive Formation (hard shale, calcites, mudstones, chert, pyrite, granite, quartzite, and cherty lime stones).

Advantage:

advantage of tci drill bit.pdf

Thread protected to prevent it damaged during transportation.

The above represents commonly available sizes and types, we do produce other sizes and types of rock drill bits which do not appear on . Please contact us for more

information.

information.