BEIJING KOREA TECHNOLOGY CASTER CO.,LTD |

|

Introduction of caster surface treatment

methods and advantages

At present, galvanized and electrophoretic methods are generally

used for caster surface treatment.

These two methods are widely used because of their obvious

advantages, as follows:

Advantages of galvanized surface treatment

1. The coating has strong toughness, and the zinc coating forms a

special metallurgical structure,

which can withstand the mechanical damage of casters during movement and use;

2. Comprehensive protection, every part of the plated parts can be

galvanized, even in the universal

wheel, caster depression, sharp corner and hidden place can be fully protected;

3. It does not affect the welding. The hardware surface can still

be welded after galvanizing treatment,

such as spot welding after assembly.

4. The treatment cost is low, and the cost of galvanizing and rust

prevention is lower than that of other

paint coatings;

5. Strong rust resistance, castors after galvanizing are not easy

to rust for many years;

6. Good reliability. The zinc coating and steel are metallurgically

combined to become a part of the

steel surface, so the durability of the coating is more reliable;

Advantages of electrophoretic surface treatment

1. Good impact resistance and artificial perspiration resistance;

2. It can electrophoretic various colors, such as black, coffee,

red, blue, green and so on. Combined

with matte ions, it can also achieve various effects such as semi dumb.

3. High strength. When baking at 150 ℃, the hardness can reach

3-4h;

4. Good leveling, strong film feeling and good film slip feeling;

5. Good adhesion and permeability, the coating is all pervasive,

and the adhesion of wet film and dry

film is strong;

6. It has good color change resistance and anti-corrosion

performance. When the baking temperature

reaches 180 ℃ - 190 ℃, the workpiece will not change color. In this way, the caster products have

long-lasting and gorgeous color and excellent corrosion resistance effect;

7. Good electrophoretic uniformity, uniform and flat paint film,

which can reach 10-25um within 30-150v,

high efficiency and low power consumption;

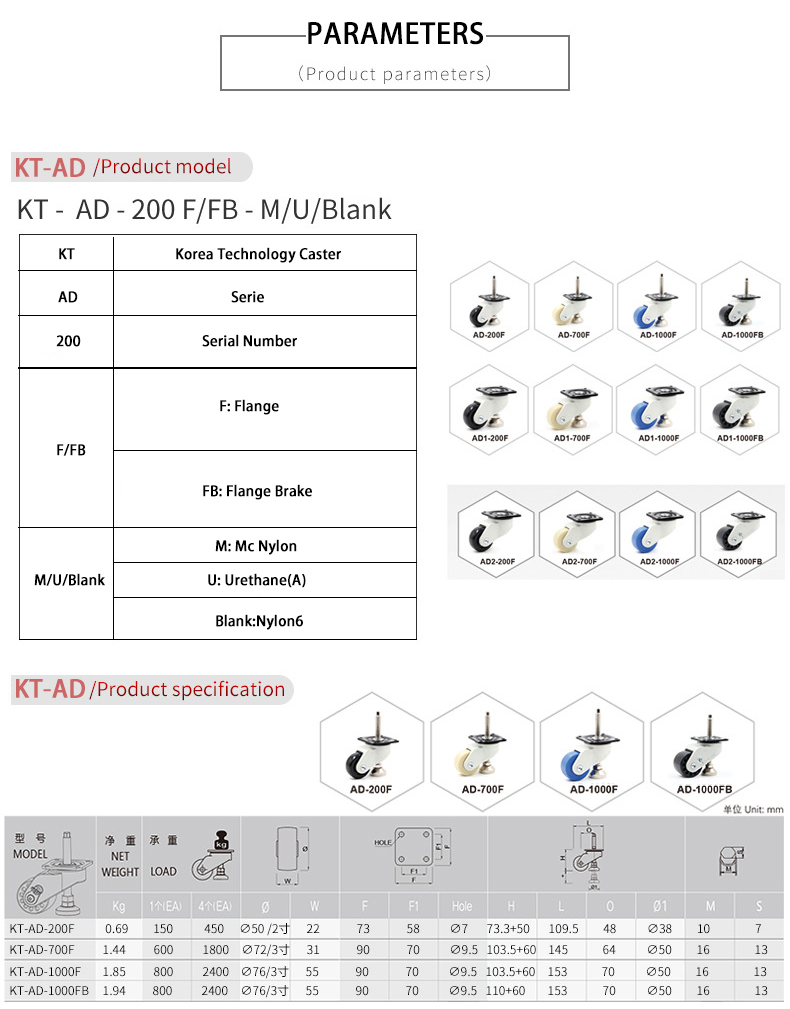

AGV Casters Parameter

| model | KT-AD1-1000FB-U |

| Net weight | 1.73KG |

| Single bearing | 800KG |

| Four load bearing | 2400KG |

| texture of material | polyurethane |

| type | Flange Brake |

| Load Height | 110+12MM |

AGV Casters Describe

AGV Casters Size

AGV Casters Material

| Name | Material | Treatment | |

| 1 | Caster Seat | SPC | Blank/Powder Coated |

| 2 | Ball | STB2 | Ni-Cr |

| 3 | Body | ALDC12 | Ivory/Powder Coated |

| 4 | Cup | ALDC12 | Ni |

| 5 | Brake | S45C | Zn Galvanized |

| 6 | Pin | S10C | Zn Galvanized |

| 7 | Wheel | PA6 | Black |

AGV Casters Scope of application

KTC (Bejing Korea Technology Caster Co., Ltd.) was founded in 2007. KTC is a modern

company specialzingin the production of multi function &high quality CASTER and

KT FOOT based on best design and design technology.

The company is headquartered in Niulanshan Industrial Zone,Shunyi District, Beijing. KTC

adopts international advanced production testing equipments, professional intelligent

production management system and professional design flow. Now the company produces

multi function & high quality production, such as KT CASTER and KT FOOT, among which

high quality of height adjusting CASTER,shockproof type CASTER, high quality of height

adjusting CASTER, shockproof type CASTER,high load CASTER and level adjusting FOOT

are widely used in the world's advanced automation equipment and semiconductor e

quipment industry.

In order to manufacture the world's highest level of products,KTC

use the best processing

technology and equipment. And KTC continuously launches world top level of new products.

KTC's s also has set up a branch in Korea, so it is favored by theusers of various fields around

the world.